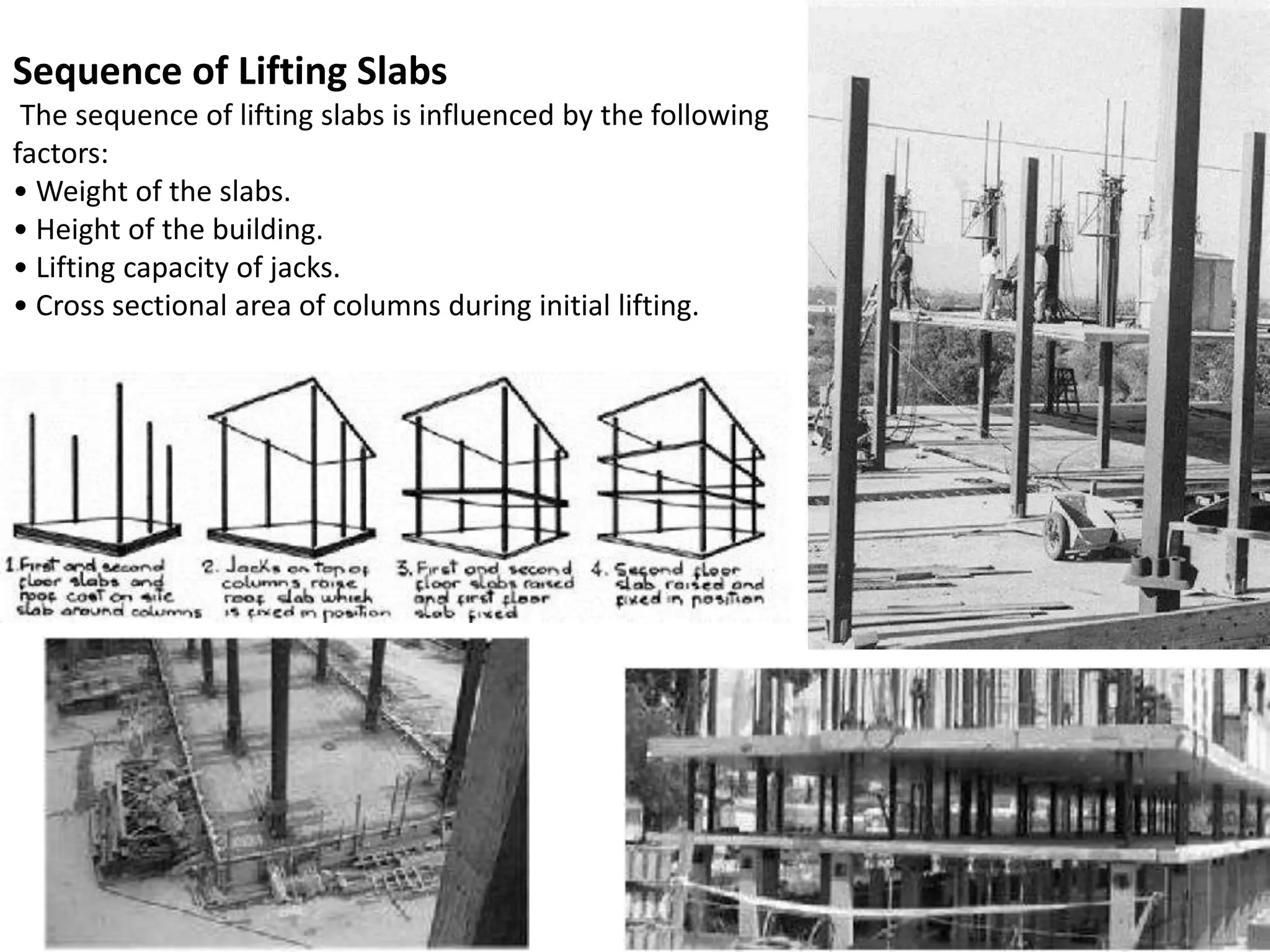

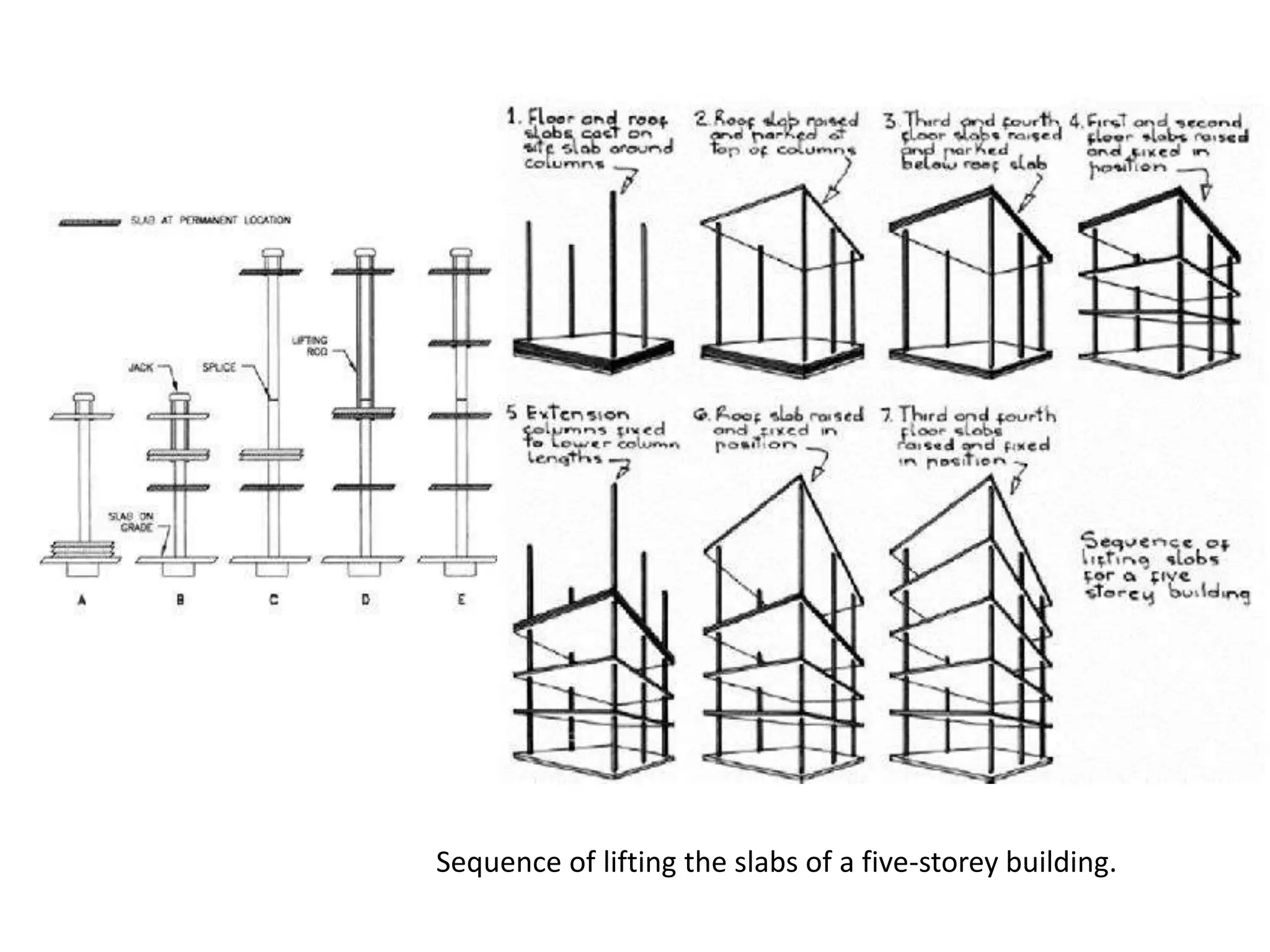

Lift slab construction is a method of building concrete structures by casting floor or roof slabs on top of previous slabs and then lifting them into place with hydraulic jacks, making it cheaper and faster than traditional cast-in-place construction. Powerful jacks lift the cured slabs into position while ensuring even lifting at all points. This method is most effective for buildings with uniform, repetitive floor plans up to around 16 stories tall.