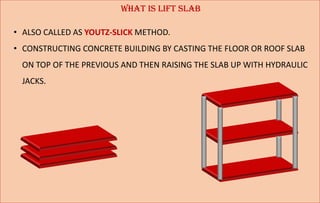

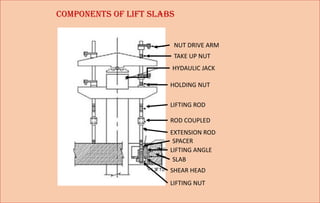

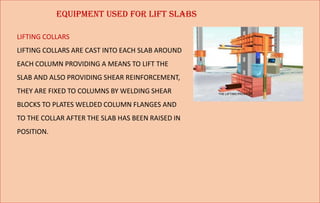

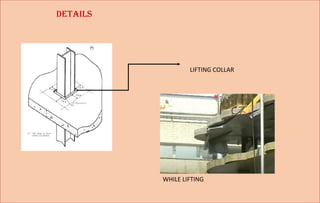

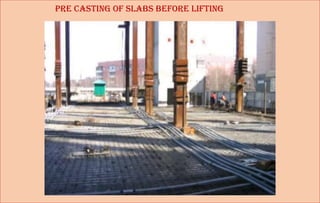

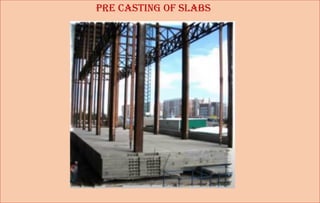

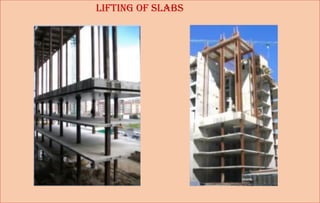

The document discusses lift slab construction, which involves casting concrete floor or roof slabs on top of previous slabs and then raising them with hydraulic jacks. This allows work to be completed at ground level instead of forming floors in place. Lift slab construction is useful for quickly creating structures with repetitive floor plans like parking ramps. Key equipment includes hydraulic jacks, lifting collars cast into each slab, and shear blocks to hold slabs in place once lifted. The process involves casting slabs, applying bond breakers, then sequentially lifting slabs using jacks as the building rises.