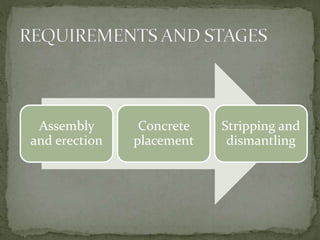

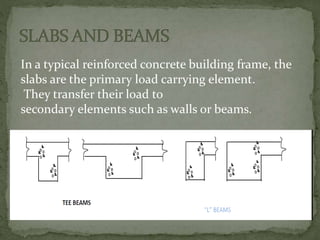

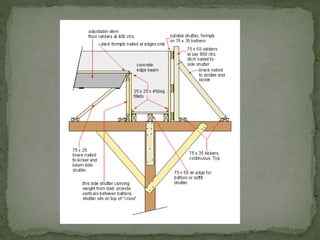

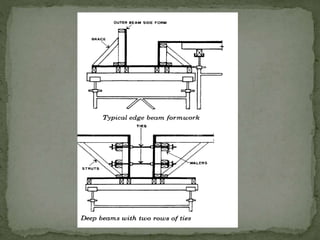

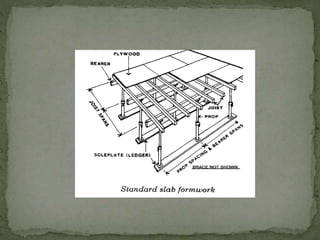

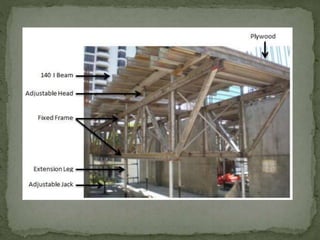

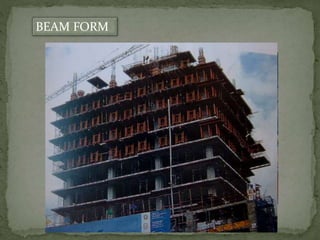

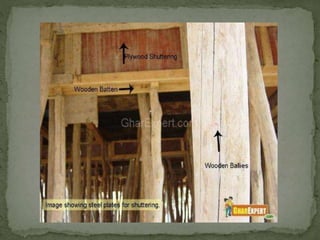

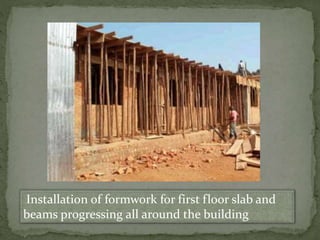

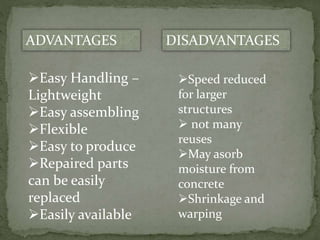

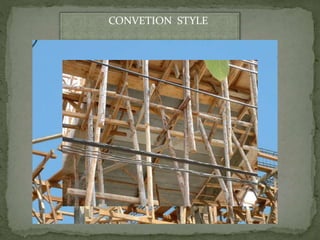

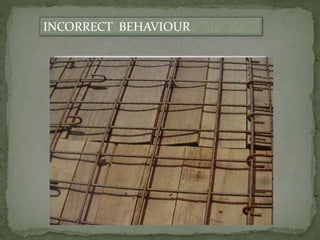

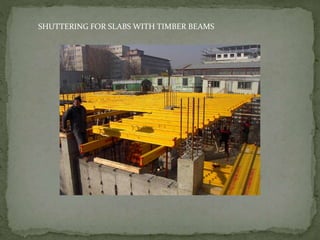

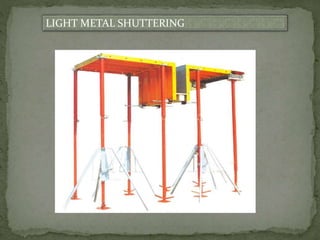

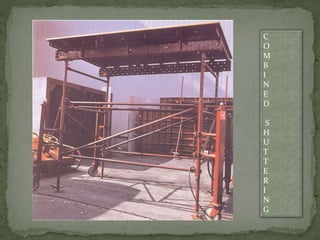

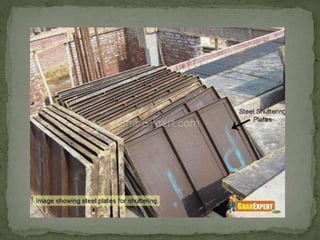

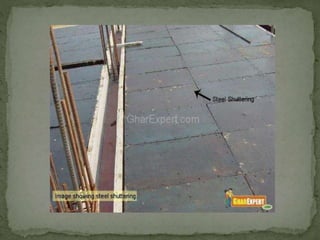

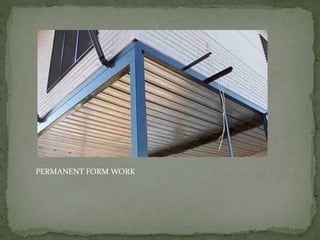

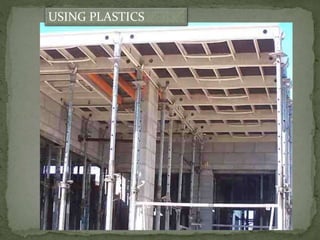

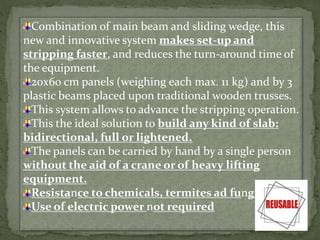

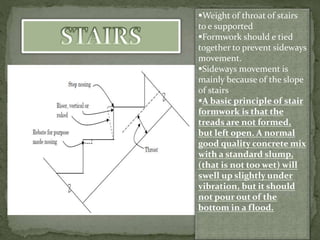

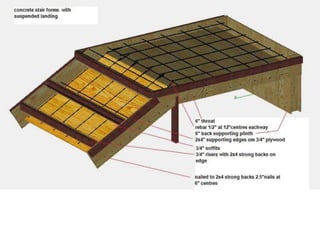

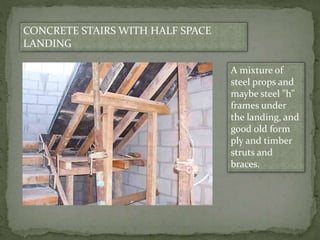

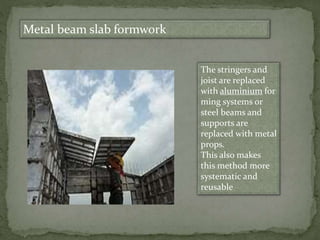

Formwork is used to mold concrete into desired shapes for slabs, beams, stairs, and other structures. It is made from various materials like wood, plywood, steel, aluminum, and plastics. Proper formwork design and installation is important for quality, safety, and cost-efficiency. Formwork must be assembled correctly, have concrete properly placed, and then stripped at the right time. Different formwork techniques exist for slabs, beams, stairs, and other elements. Factors like reusability, weight, cost, and construction speed influence the choice of formwork material and system.