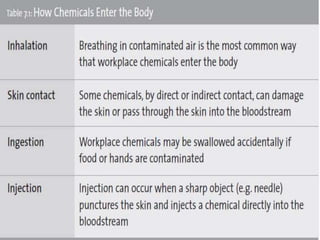

This document provides an overview of chemical safety in the workplace. It discusses common chemicals that are hazardous, how chemicals can enter the body, and the importance of risk assessment. The key steps for risk assessment are outlined, including making an inventory, collecting safety information, assessing exposure, and implementing controls. Control methods like substitution, engineering controls, administrative controls and PPE are described. Proper chemical storage, labeling, training and emergency response are important for effective chemical management.