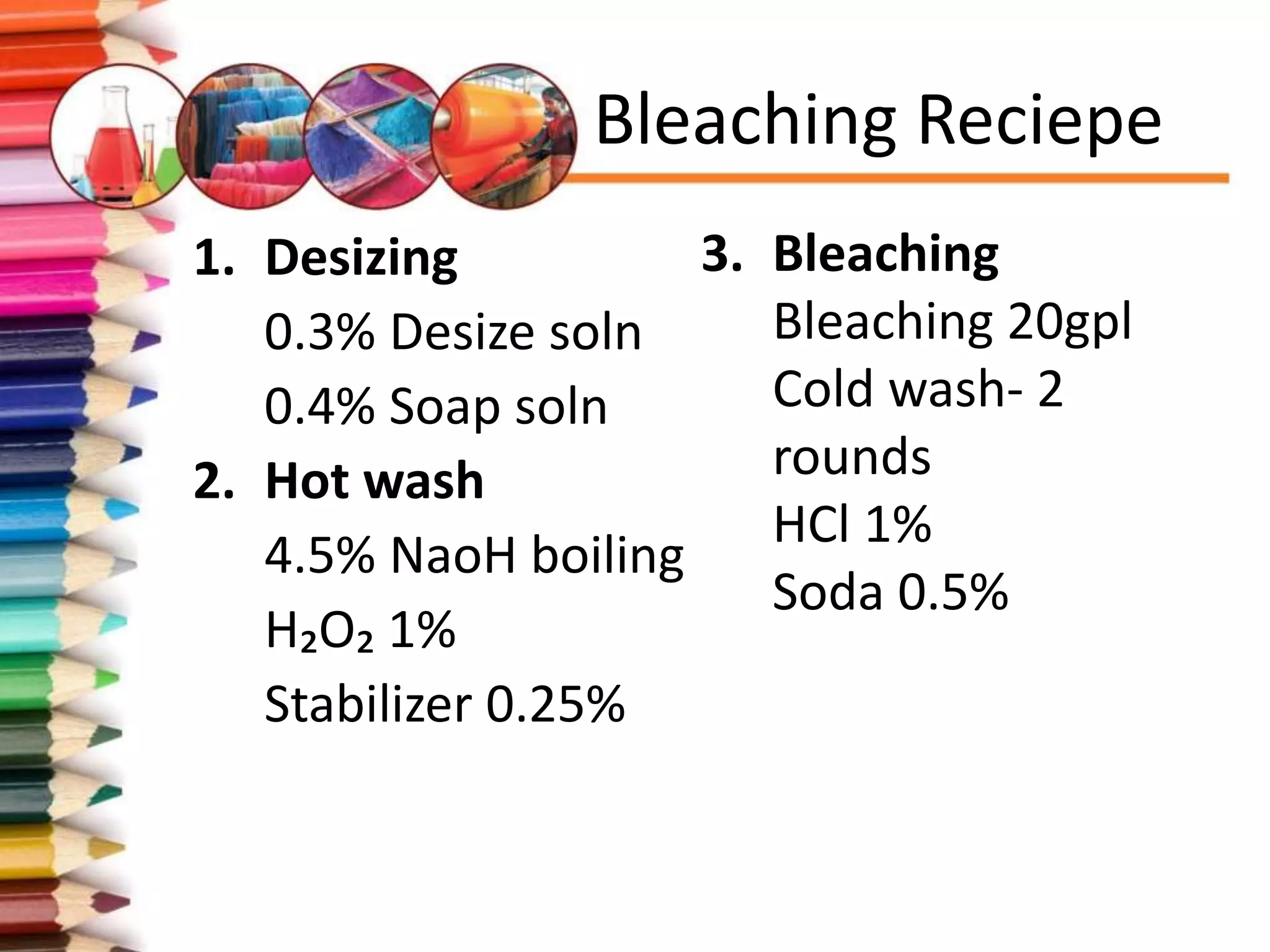

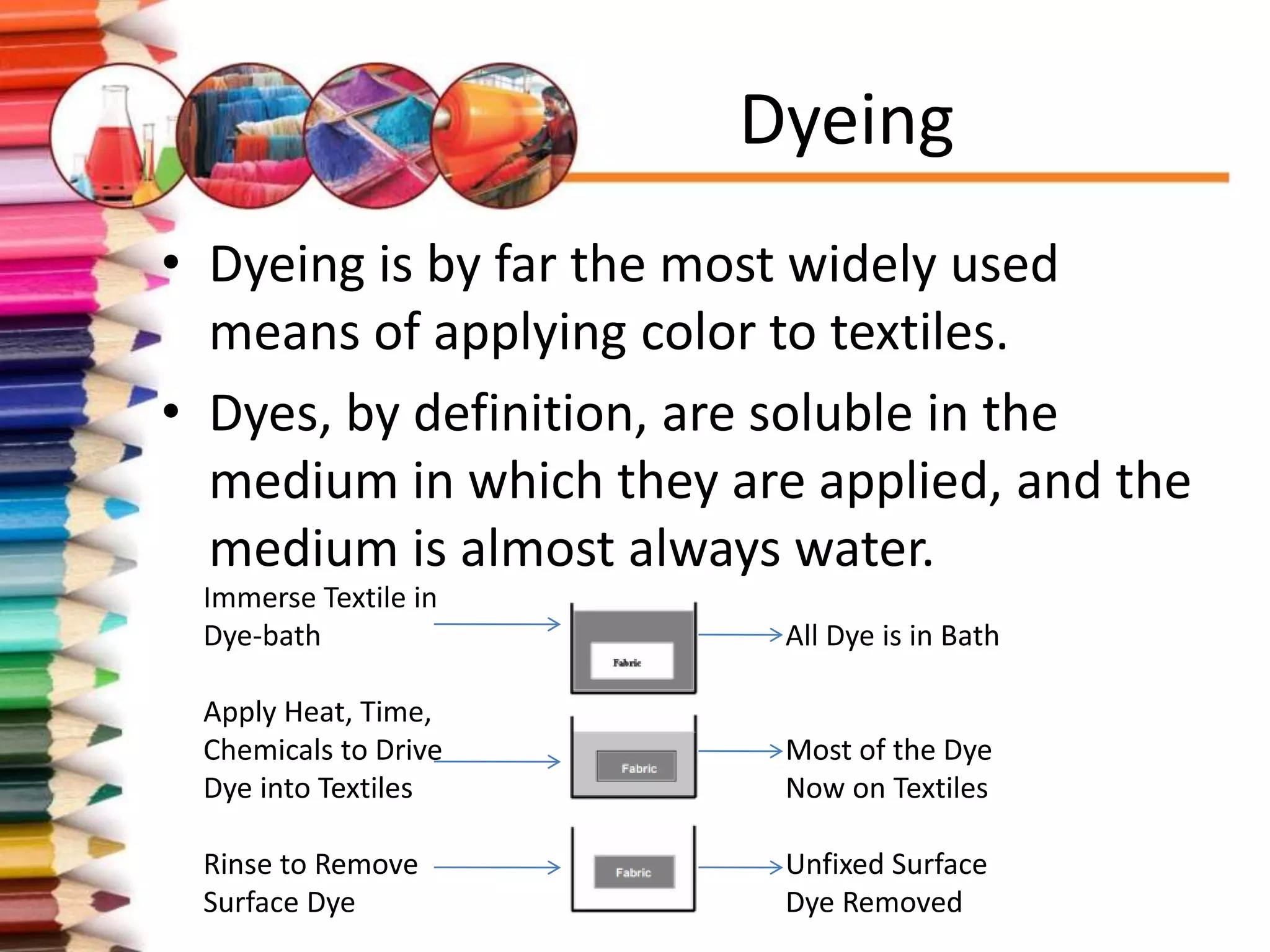

The document discusses various textile processing techniques. It begins by explaining preparatory processes like singeing, desizing, scouring, bleaching, and mercerization that are used to clean and prepare fabric for further processing. It then covers dyeing methods like reactive, vat, direct dyeing. Other topics include shrinkage control finishes and effluent treatment plants used to treat industrial wastewater. The conclusion reflects on the learning from the internship and challenges of capturing all textile processing details within a short report.