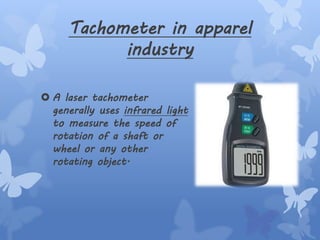

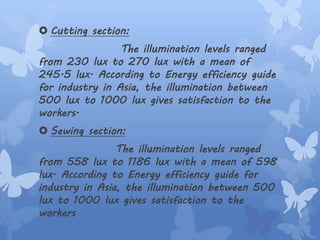

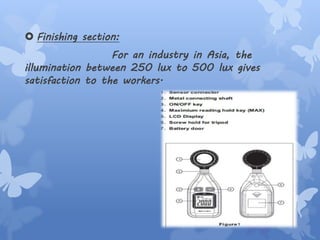

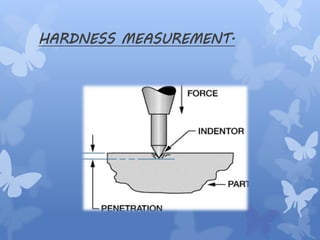

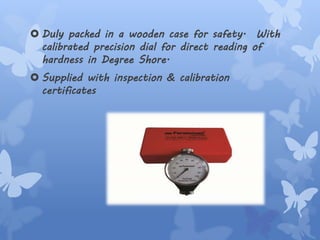

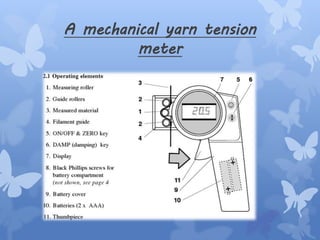

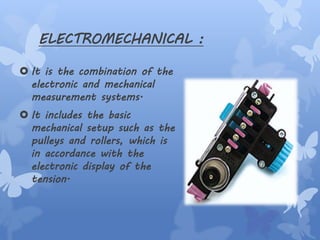

This document discusses various measurement instruments used in the apparel industry, including tachometers, lux meters, yarn tension meters, and package hardness testers. It provides details on how each instrument works and its applications. Tachometers measure rotational speed and are used to calculate sewing machine RPM. Lux meters measure illumination levels to ensure proper lighting for workers. Yarn tension meters measure tension during winding and weaving. Package hardness testers evaluate hardness of packages, cones, and rollers. All of these instruments help apparel companies monitor and control important production parameters.