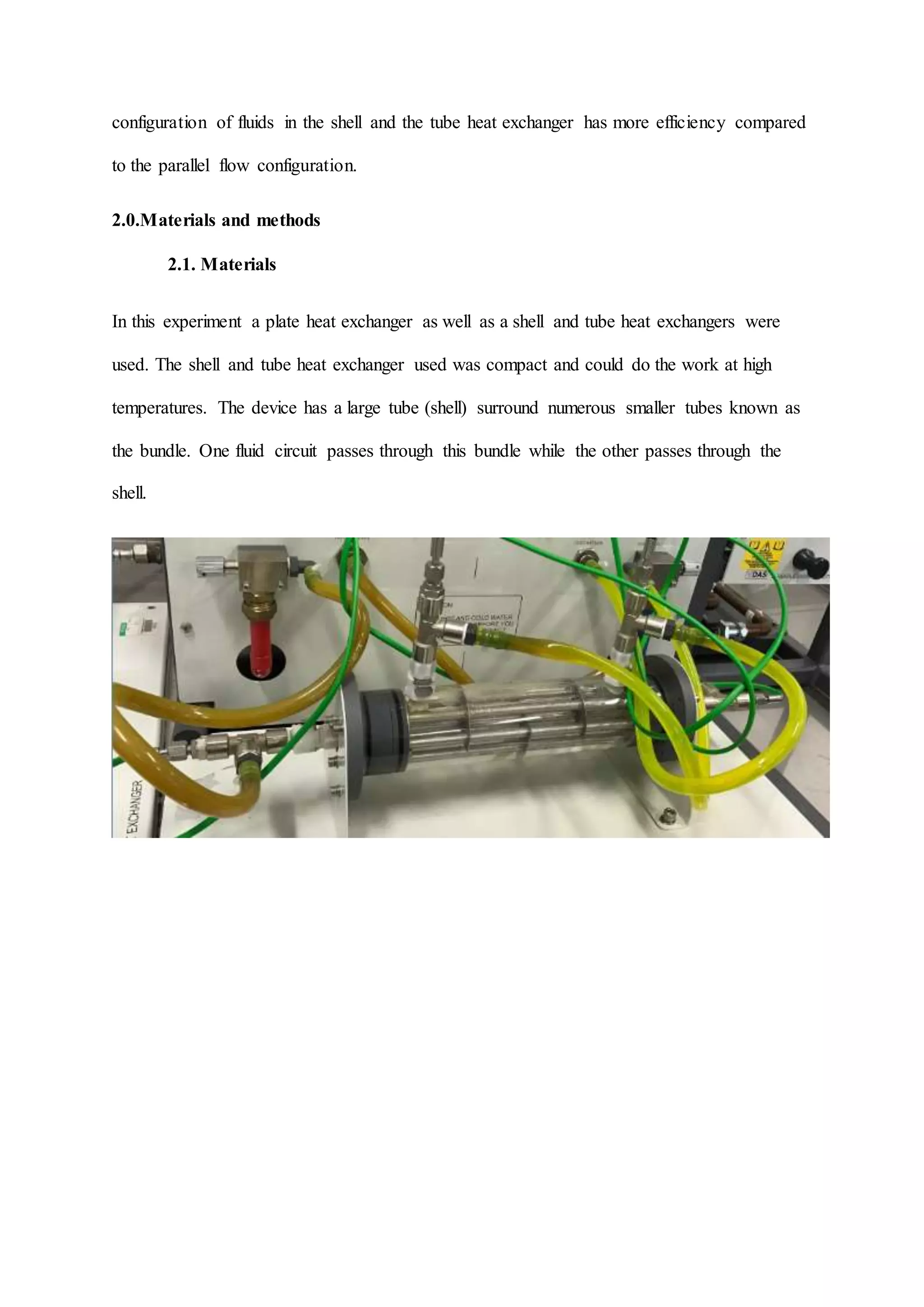

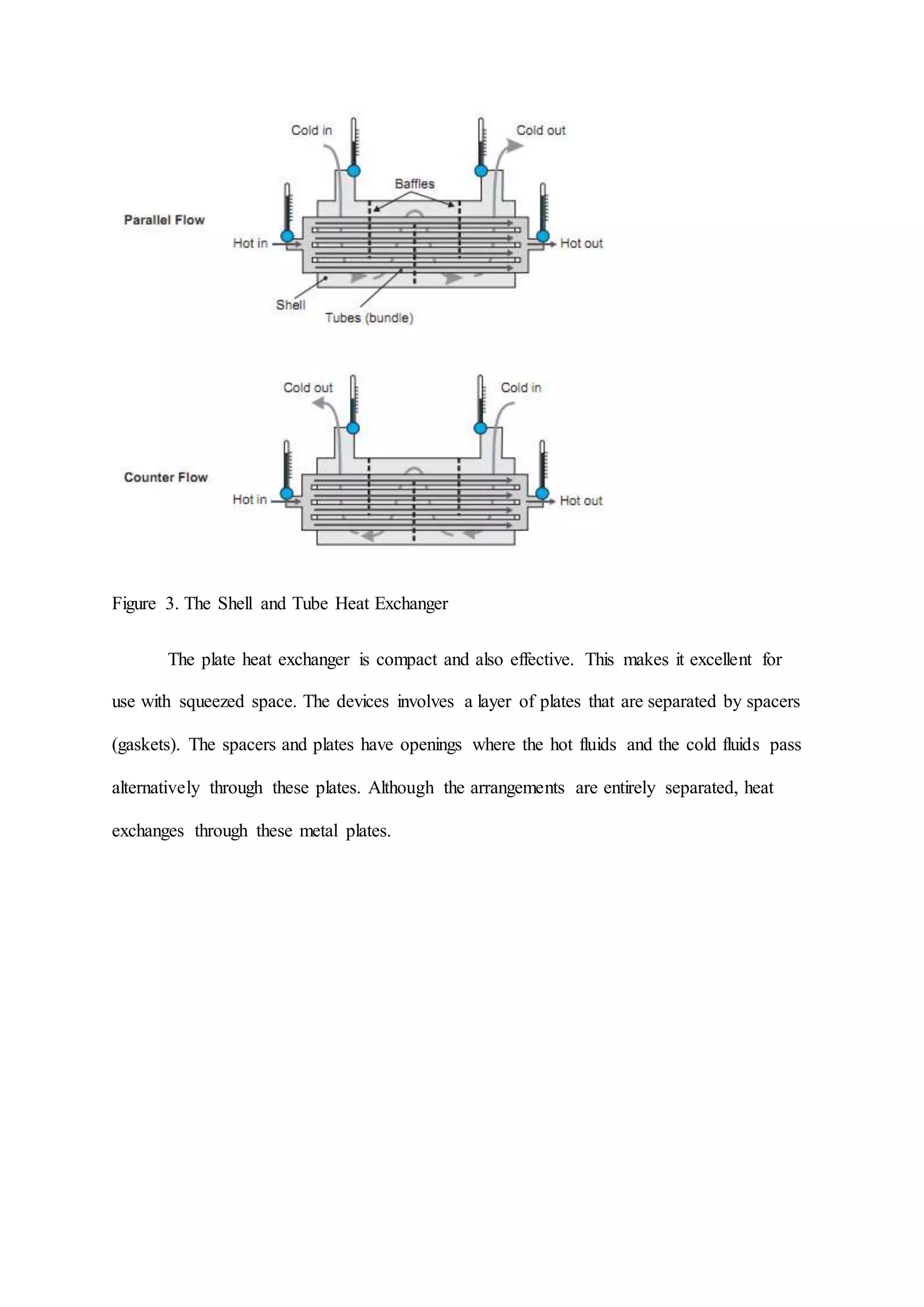

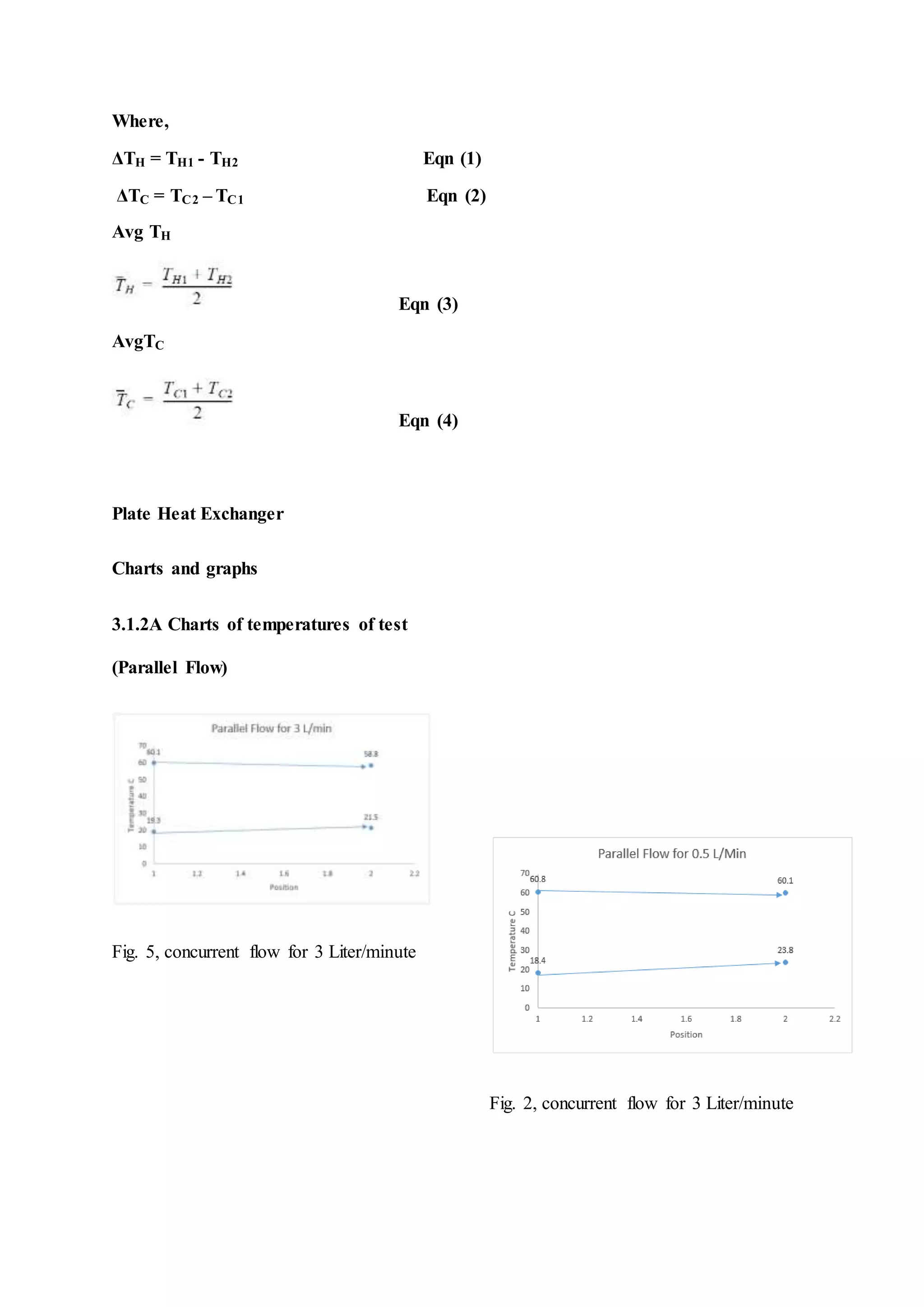

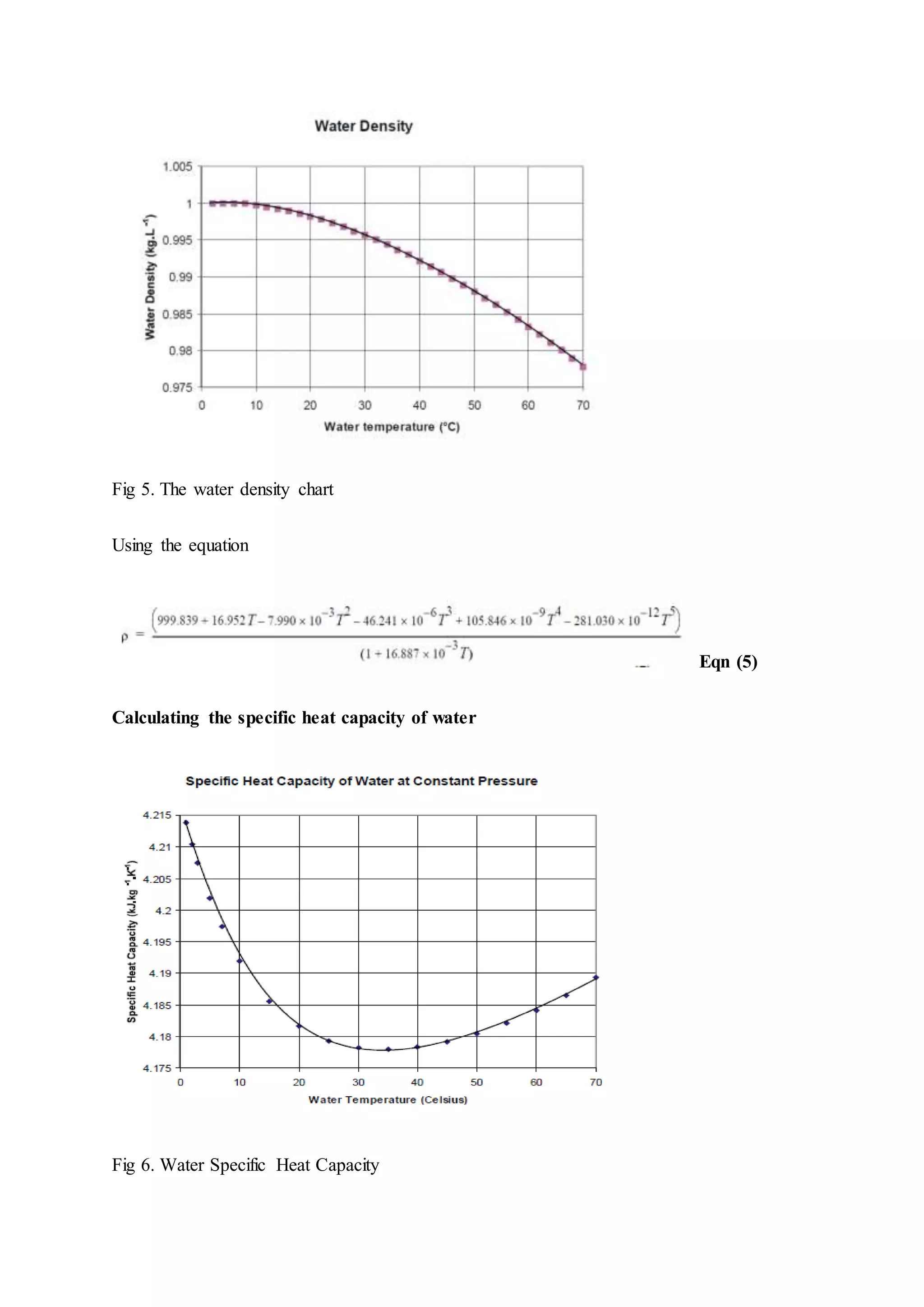

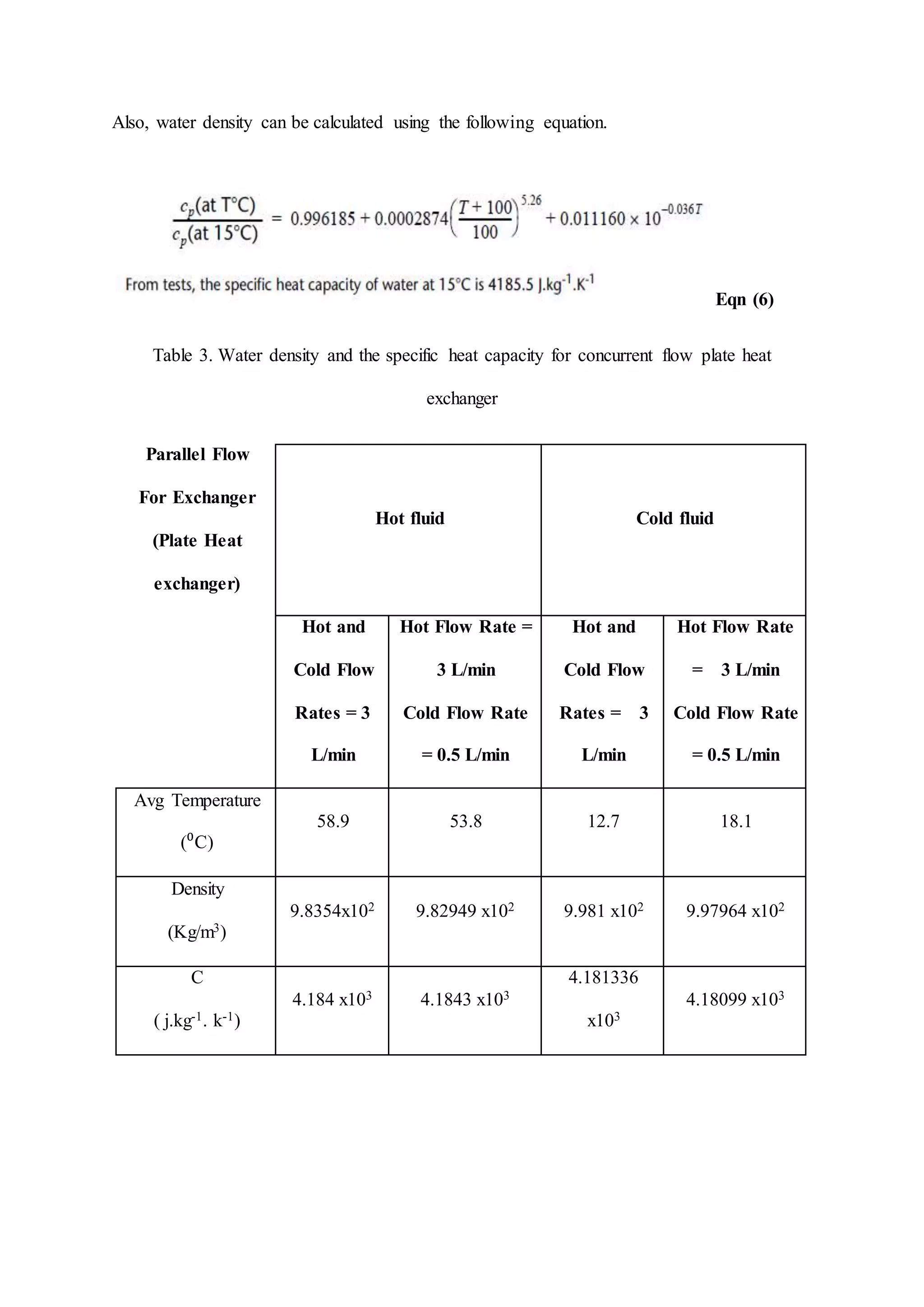

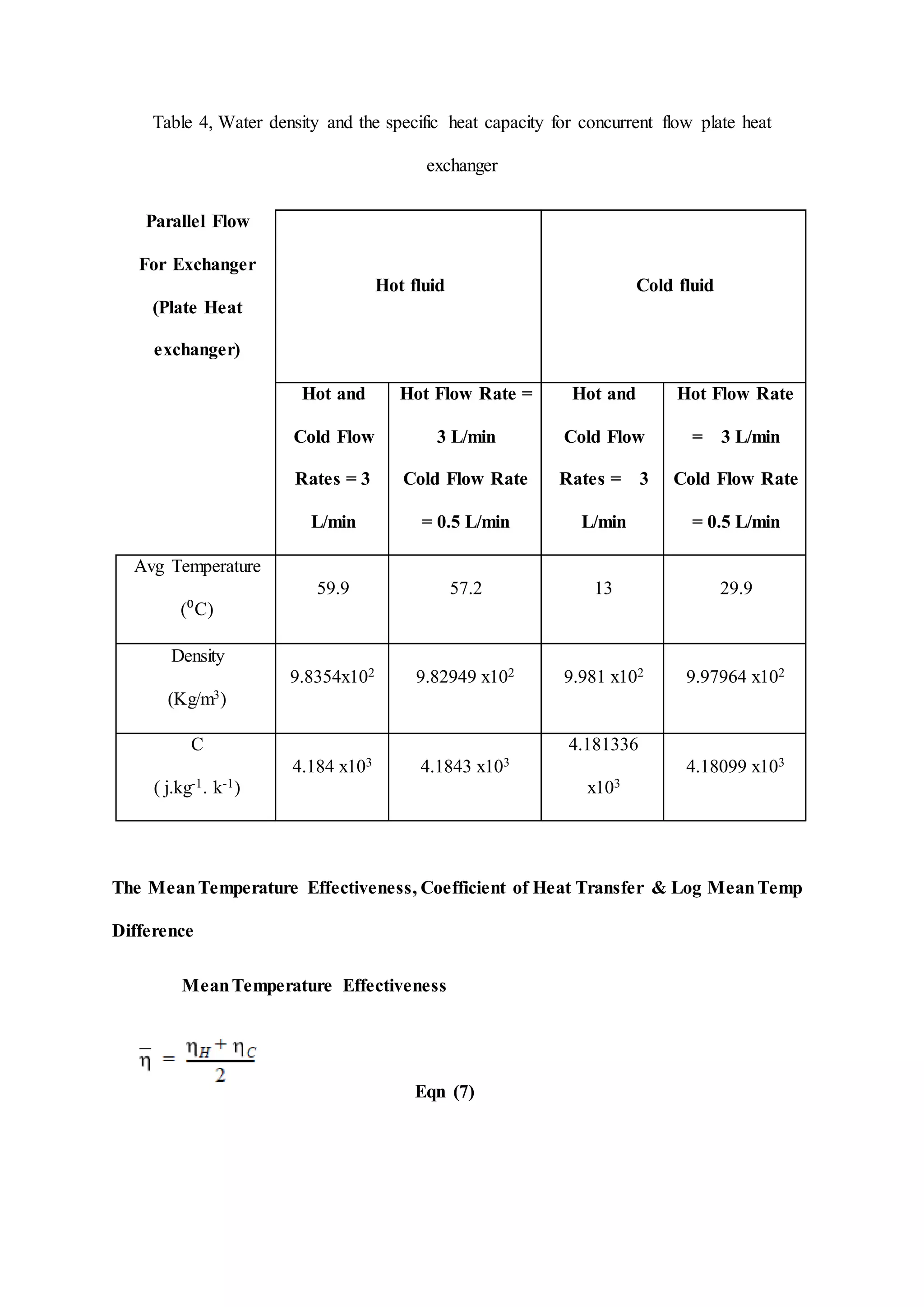

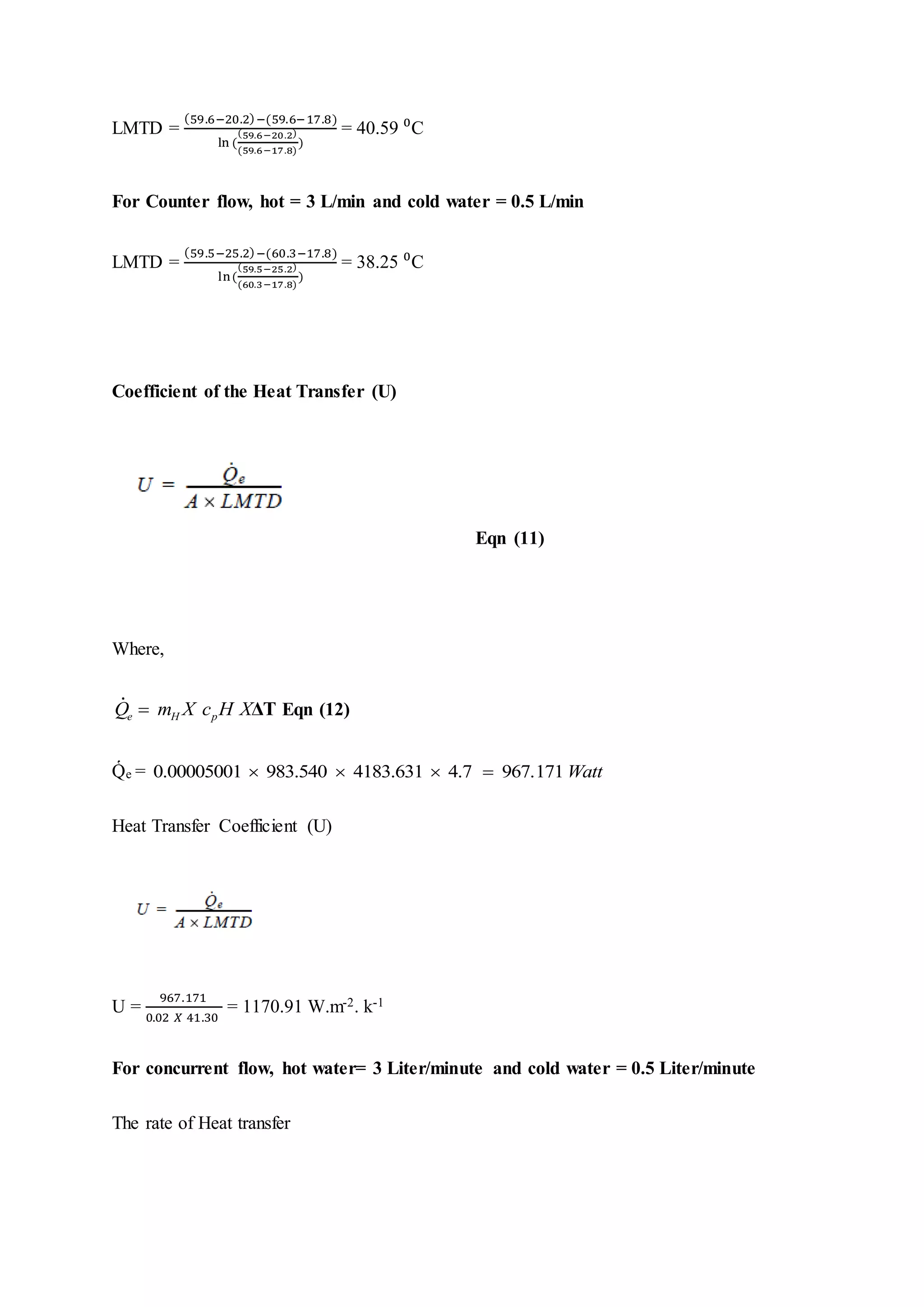

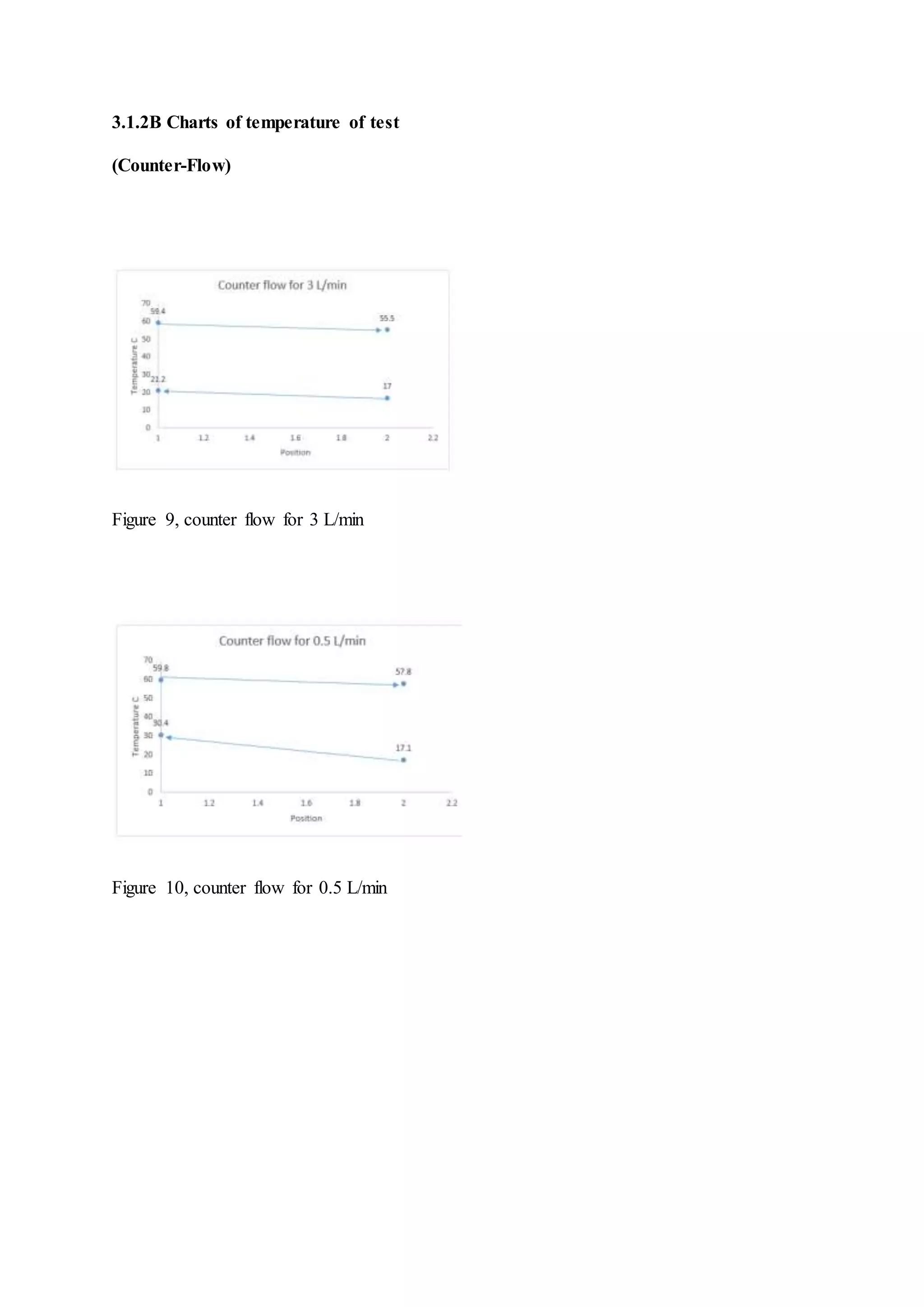

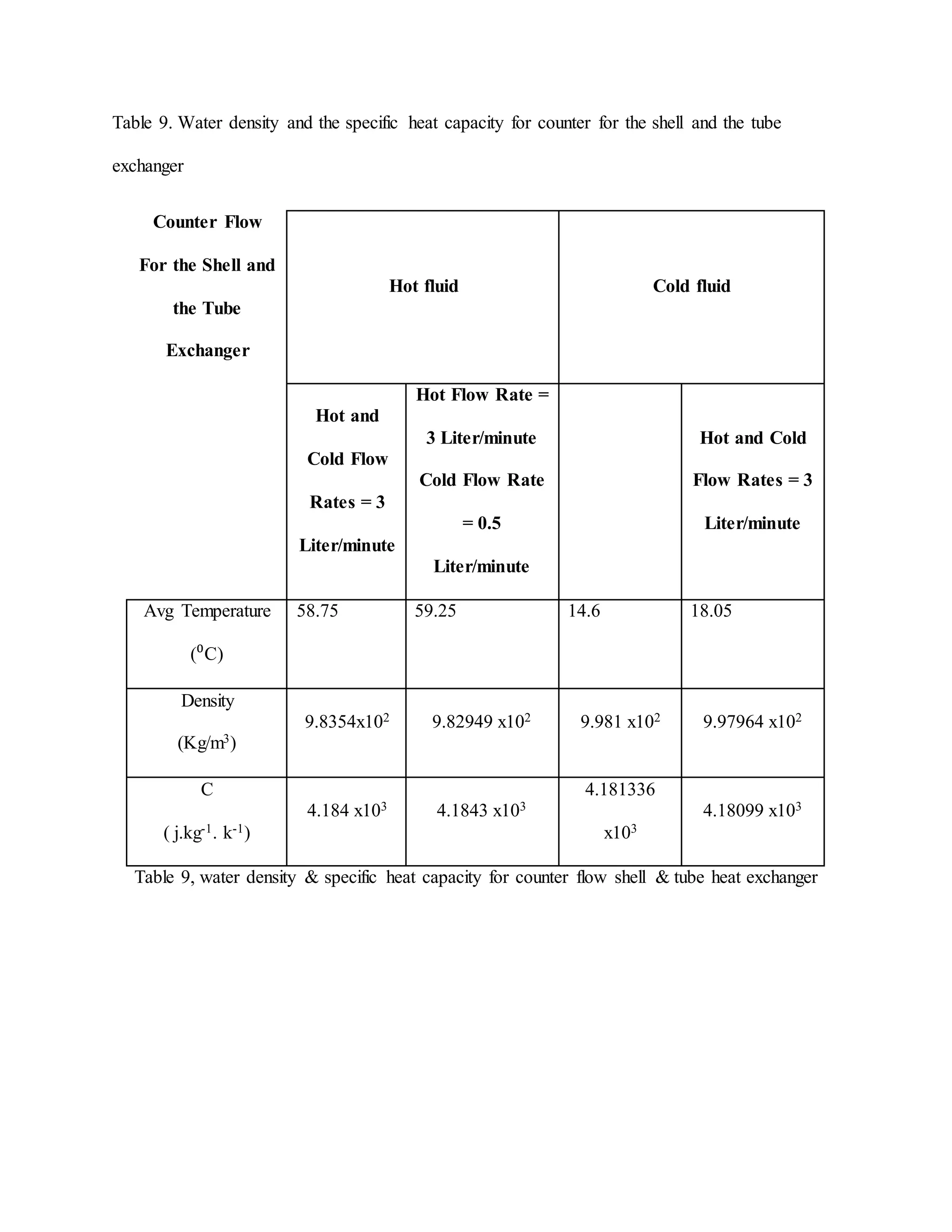

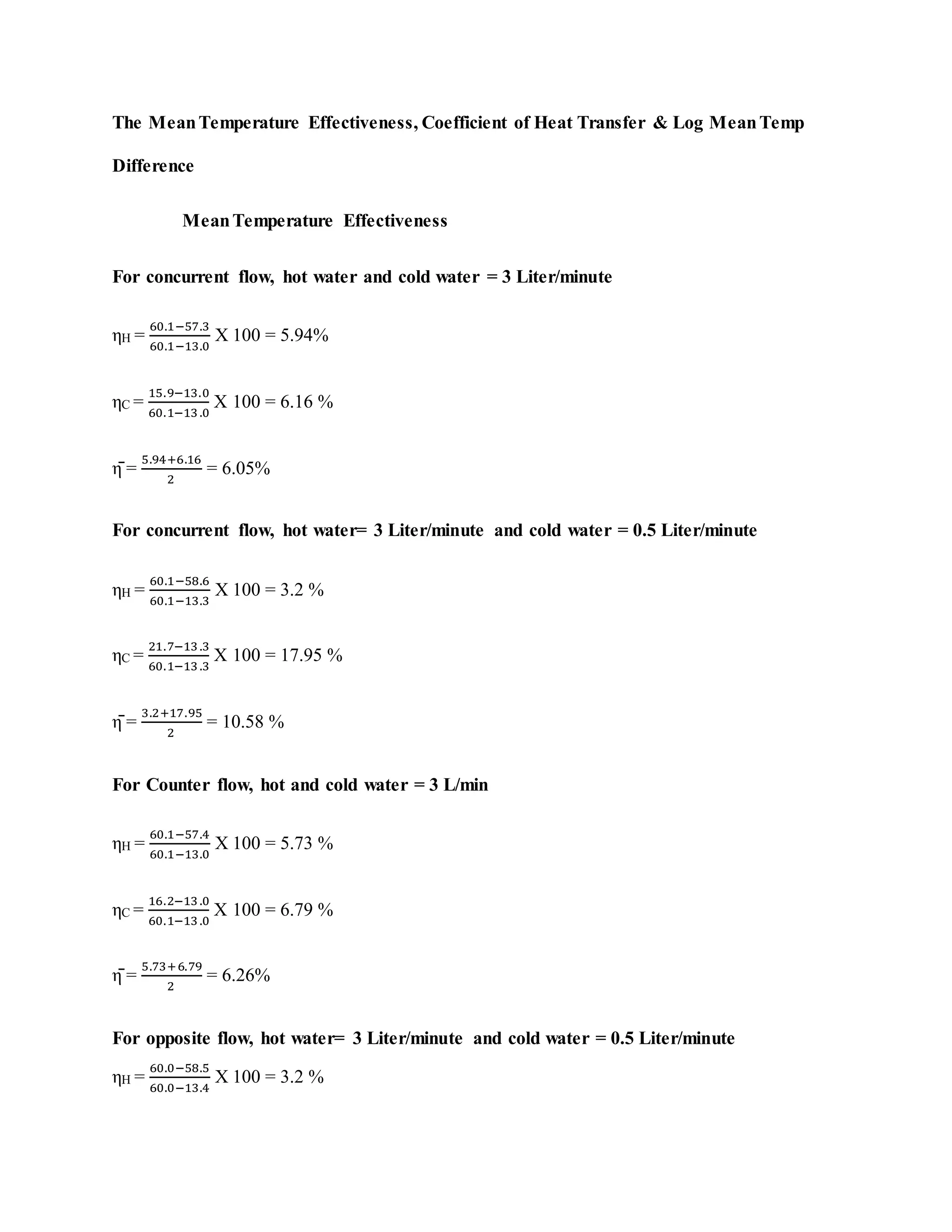

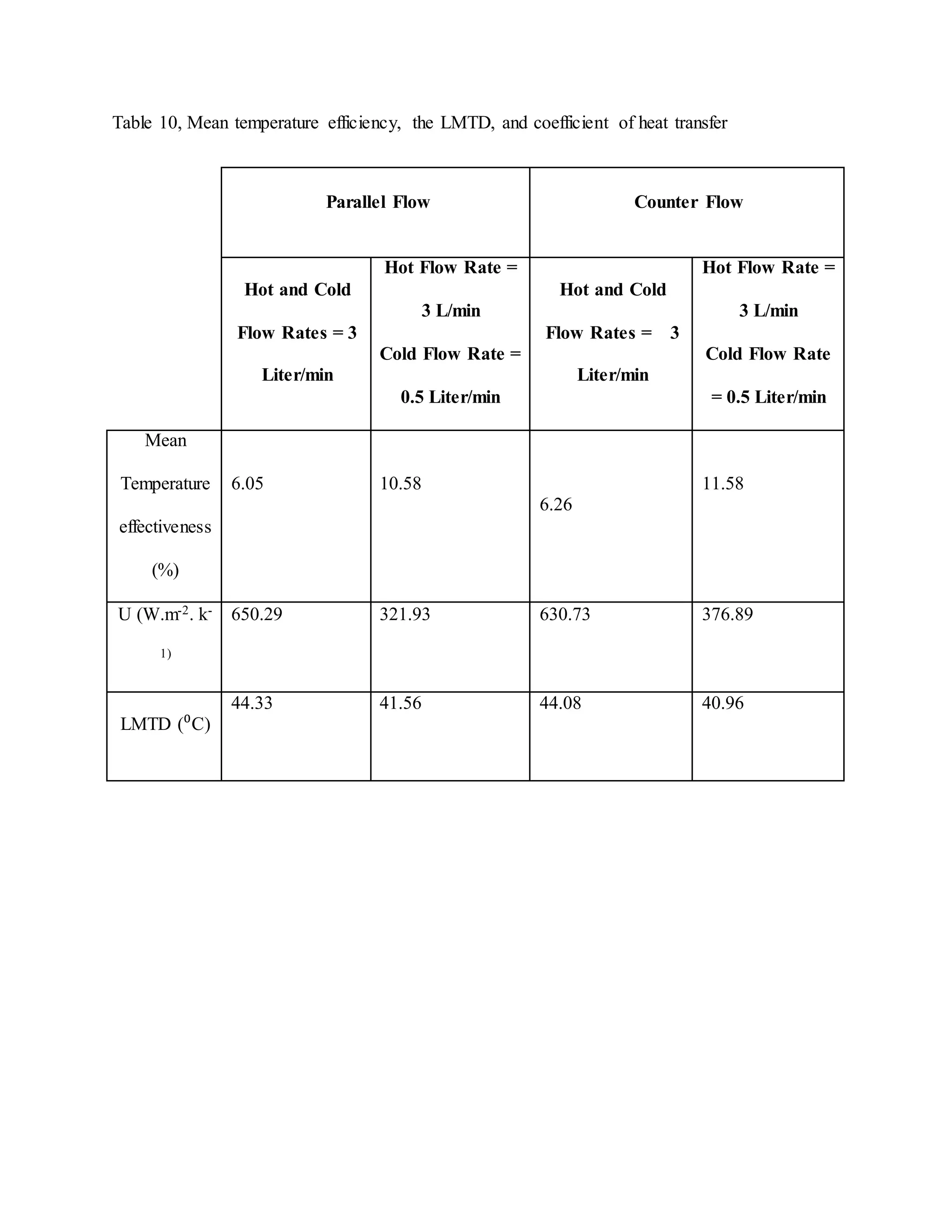

The document describes heat exchangers and experiments conducted using a shell and tube heat exchanger and a plate heat exchanger. It discusses three types of fluid flow - parallel, counter, and cross-flow. Experiments were conducted with both exchangers under parallel and counter-flow configurations. Temperature and flow rate data was collected and used to calculate effectiveness, heat transfer coefficients, and log mean temperature difference. The results showed that the counter-flow configuration had higher effectiveness compared to parallel flow in both exchangers.

![References

Kakaç, S., & Ishii, M. (1983). Advances in Two-Phase Flow and Heat Transfer: Fundamentals

and Applications Volume II. Dordrecht: Springer Netherlands.

Kirklin, P. W. (1992). Aviation fuel: Thermal stability requirements ; [papers presented at the

symposium held in Toronto, Ontario, Canada on 26 June 1991]. Philadelphia, Pa.](https://image.slidesharecdn.com/heatexchangerlab-2-190225142638/75/Heat-exchanger-lab-2-30-2048.jpg)