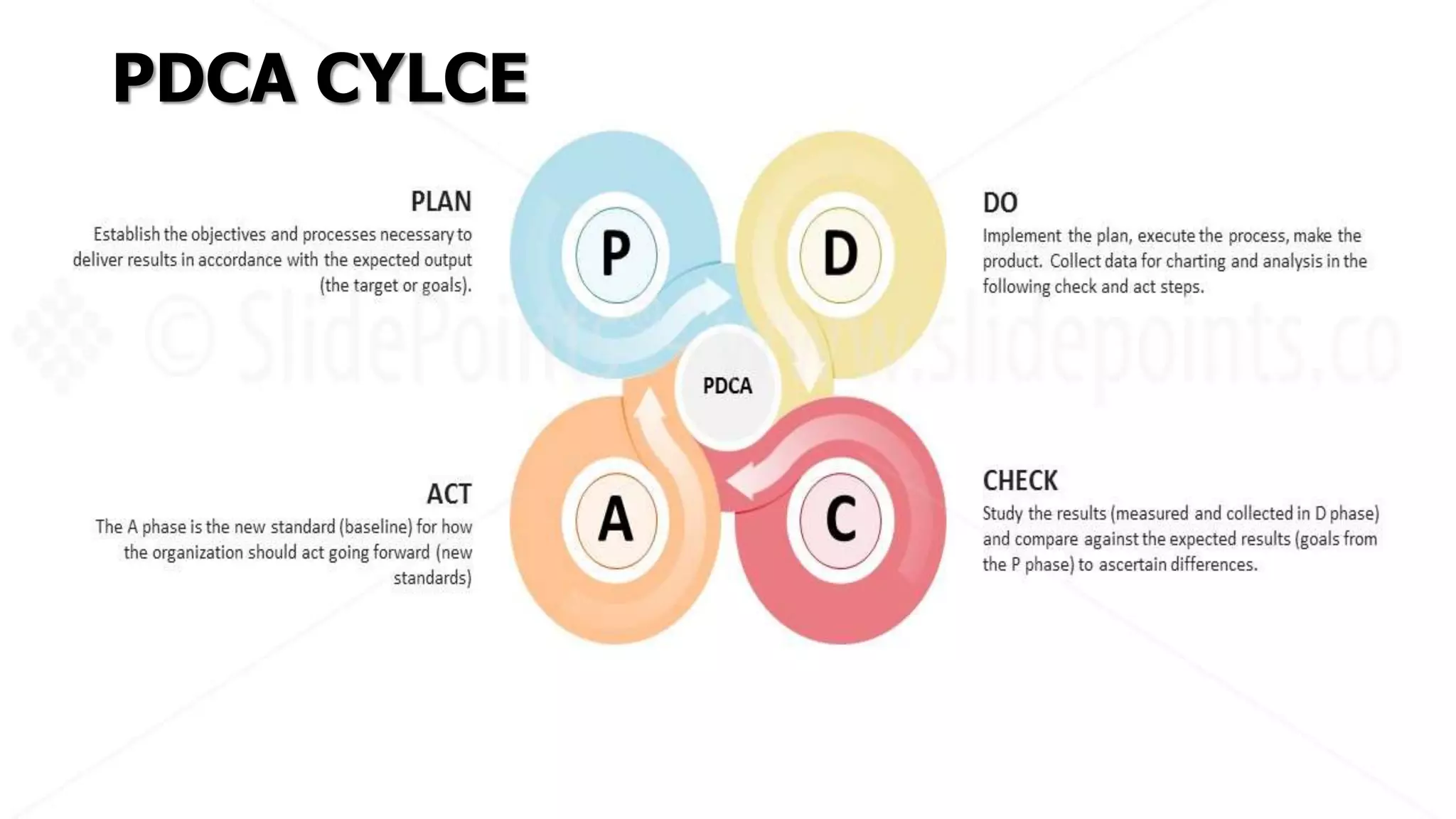

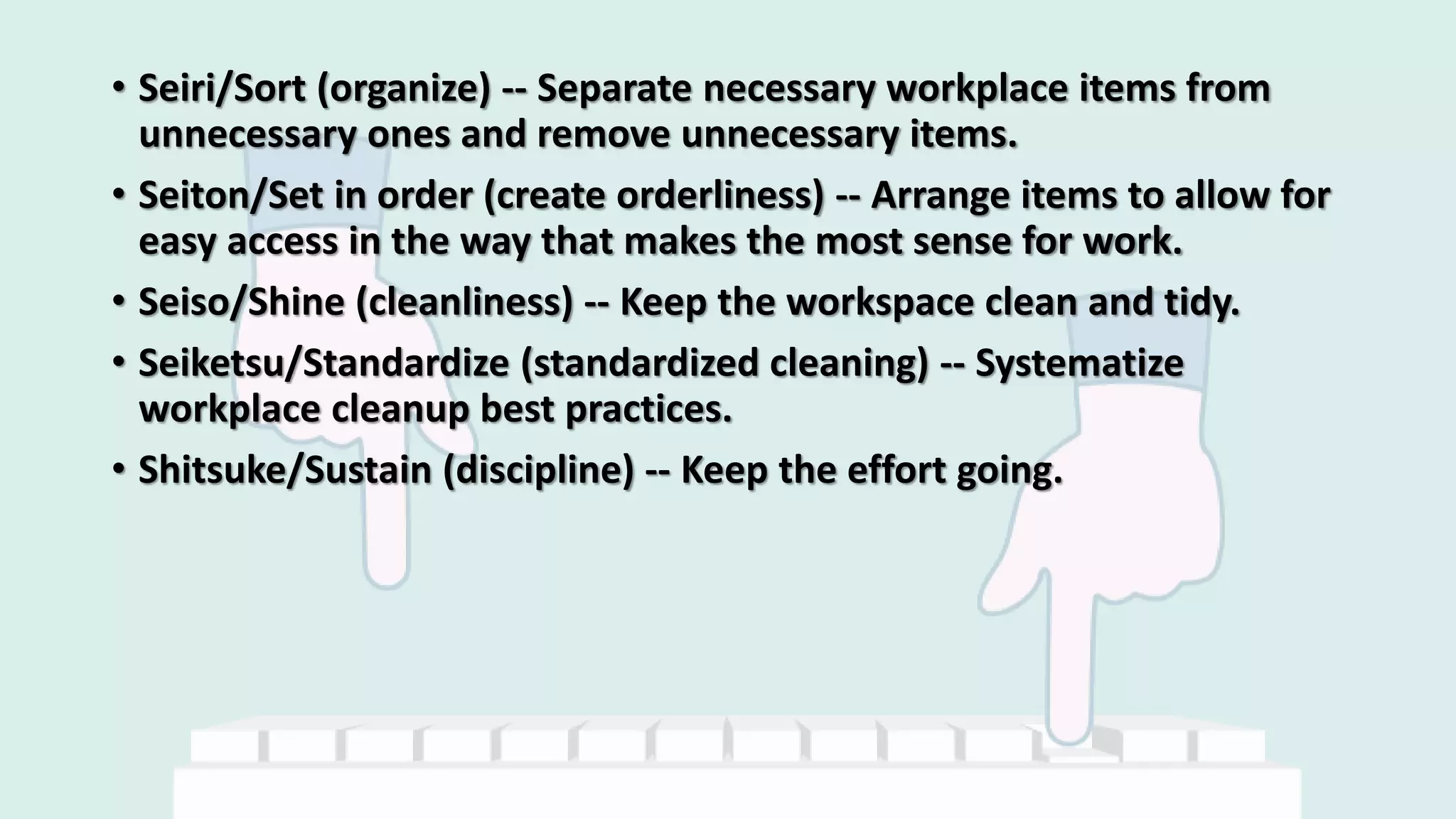

Kaizen, meaning 'good change' in Japanese, is a continuous improvement methodology central to lean manufacturing that originated post-World War II in Japan. It focuses on gradual enhancements in processes to reduce defects and waste, boost productivity, and foster worker engagement, while employing tools like the 5S framework and the PDCA cycle. Although kaizen has proven effective in various organizations, it may face challenges in cultures resistant to change and in sustaining initial excitement from short-term events.