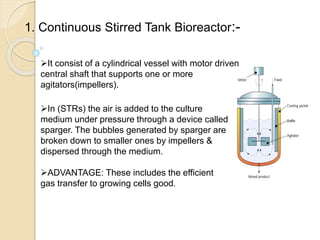

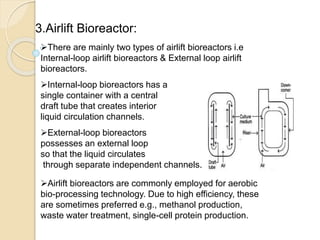

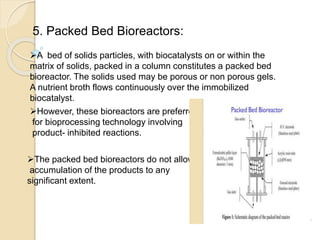

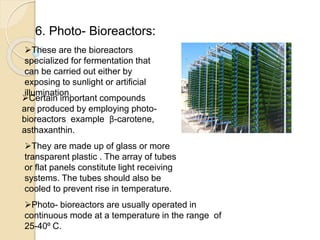

The document presents a seminar on bioreactors as part of a biotechnology skill enhancement program. It outlines various types of bioreactors, including continuous stirred tank, bubble column, airlift, fluidized bed, packed bed, and photo-bioreactors, detailing their functions, advantages, and applications in fermentation and bio-processing. The presentation emphasizes the importance of bioreactors in food processing, waste treatment, and the production of specific compounds.