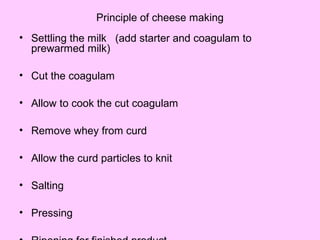

Cheese production involves several key steps:

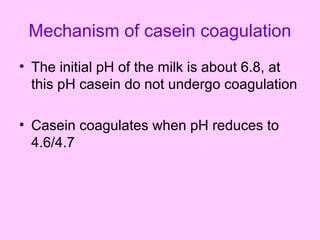

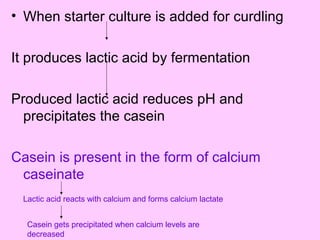

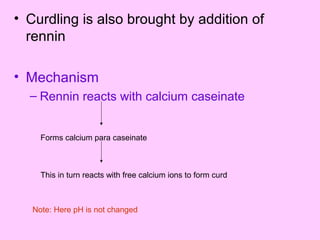

1) Curdling of milk through the addition of starter cultures or rennet, which causes casein to coagulate and separate from whey.

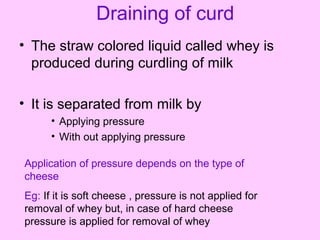

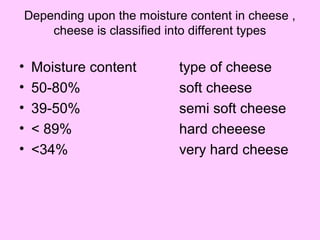

2) Draining the curd to remove moisture and separate whey.

3) Salting the curd, which acts as a preservative and controls moisture.

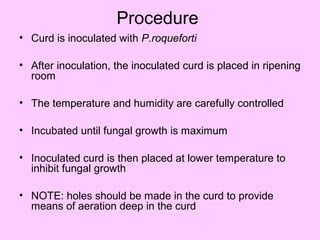

4) Ripening the curd through bacterial or mold cultures, during which flavor and texture develop.

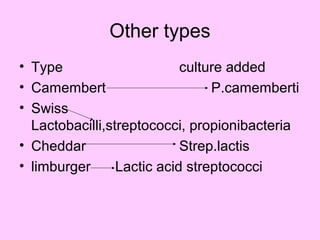

Different cheeses are produced by varying the cultures, temperatures, and other conditions during the production process.