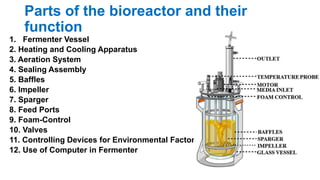

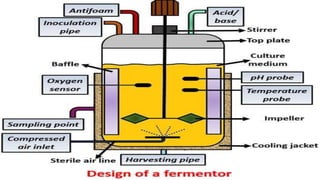

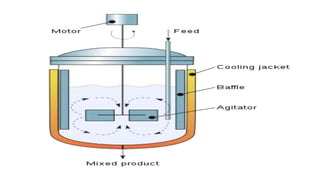

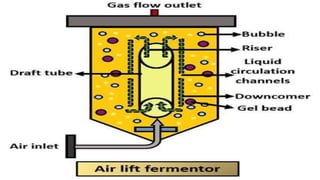

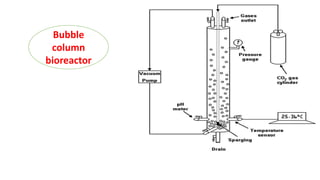

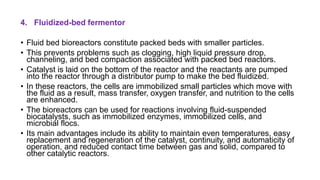

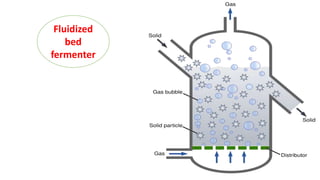

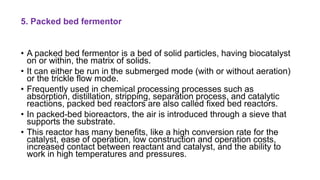

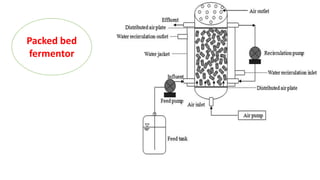

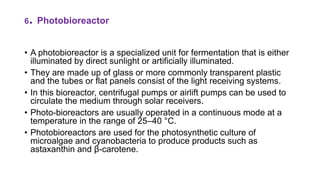

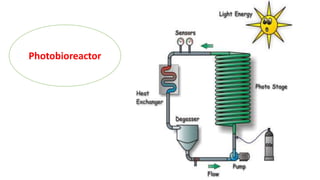

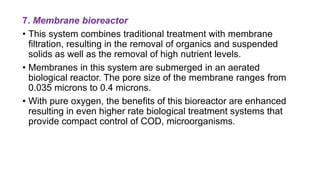

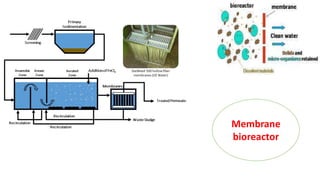

This document discusses fermentation in medicinal biotechnology. It describes fermentation as a process used to manufacture various medically important products through microorganisms or mammalian cells in a controlled environment. It outlines different types of fermentation processes including batch, continuous, and fed-batch fermentation. It also discusses various parts of bioreactors used for industrial fermentation like agitation systems, oxygen delivery systems, and controls for temperature and pH. Finally, it summarizes different types of bioreactors used in fermentation including stirred tank, airlift, bubble column, fluidized bed, packed bed, photobioreactor, and membrane bioreactors.