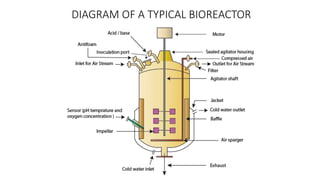

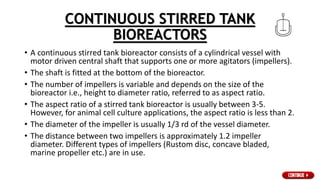

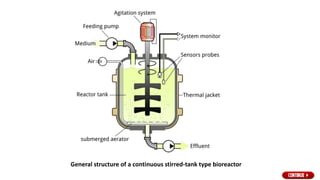

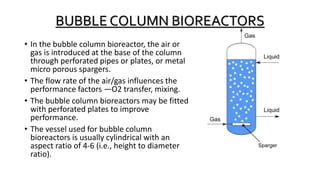

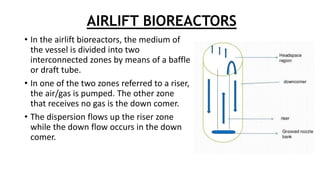

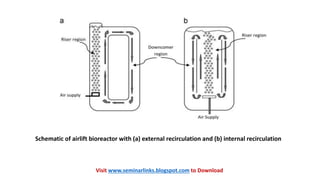

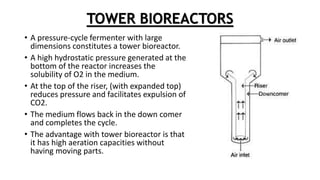

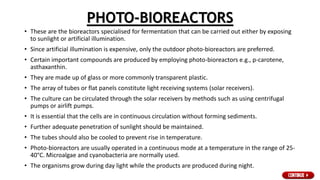

This document provides an overview of bioreactors. It begins by defining a bioreactor as a vessel that provides sterile conditions and environmental control for cell cultivation. It then describes the typical components of a bioreactor, including an agitator for mixing, a baffle to prevent vortex formation, a sparger for oxygen delivery, and a jacket for temperature control. Finally, it discusses various types of bioreactors such as continuous stirred tank, bubble column, airlift, packed bed, and photo bioreactors; and it notes that bioreactors are commonly used in food, beverage, and pharmaceutical industries.