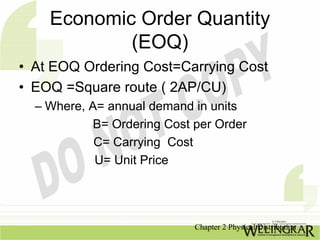

Chapter 2 covers physical distribution, defining it as the planning and control of material flows from production to end use. It discusses the components of physical distribution, including order processing, transportation, warehousing, and inventory management, and highlights the importance of balancing cost and service. Additionally, it emphasizes the relationship between physical distribution and other marketing mix variables such as product, price, and promotion.