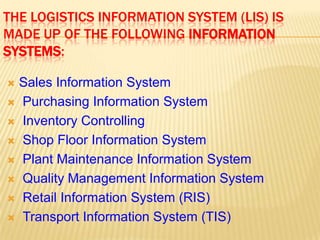

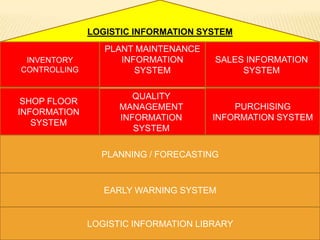

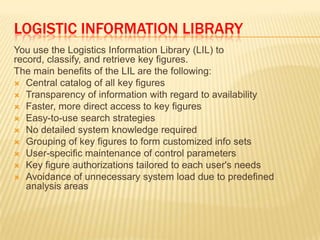

The document discusses logistics information systems and their importance. It defines logistics information systems and explains that they help achieve logistics efficiency, facilitate planning and decision making, improve competitiveness, and interface with other business information systems. The logistics information system is made up of several component information systems, including sales, purchasing, inventory, production, and transportation systems.