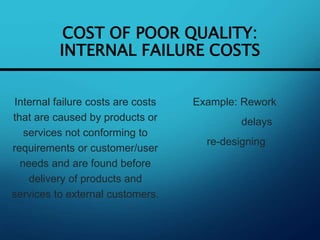

W. Edwards Deming is known as the father of quality management. He developed the Plan-Do-Check-Act cycle and his famous Fourteen Points for quality management. Joseph Juran focused on quality planning, control, and improvement through his Quality Trilogy. Philip Crosby emphasized reducing costs of poor quality and defined the Four Absolutes of quality management. Taiichi Ohno identified seven types of waste in production through developing the Toyota Production System, now known as Lean Manufacturing.