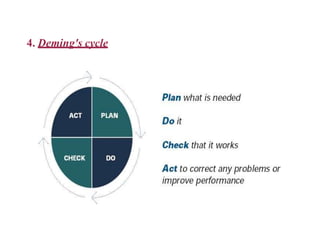

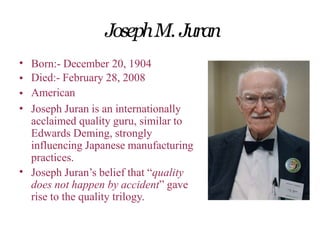

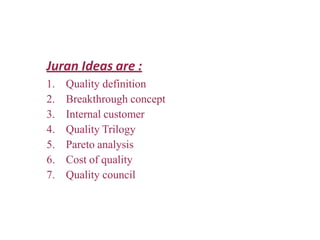

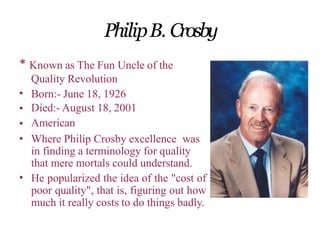

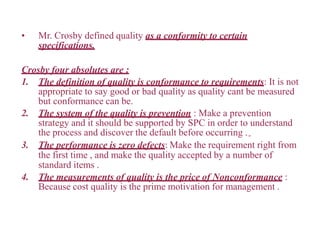

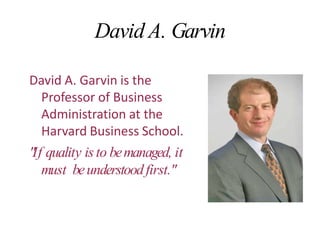

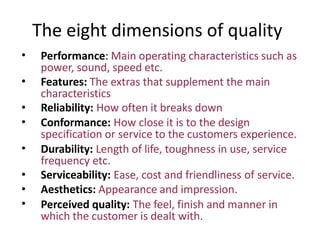

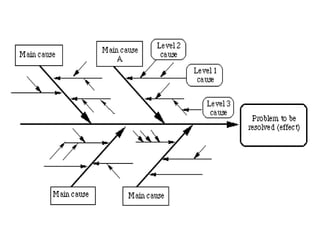

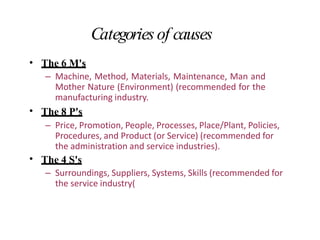

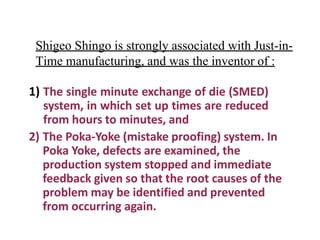

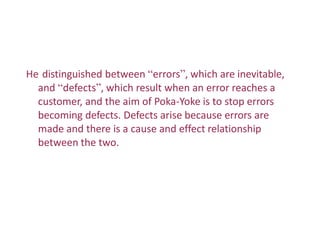

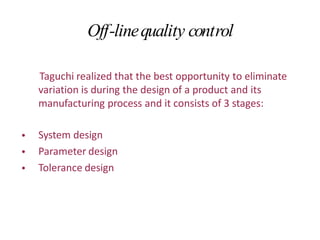

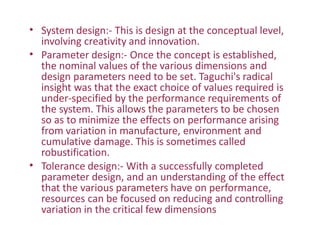

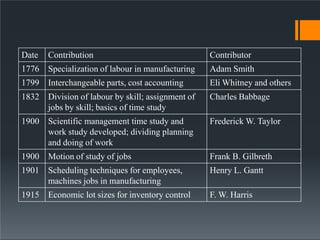

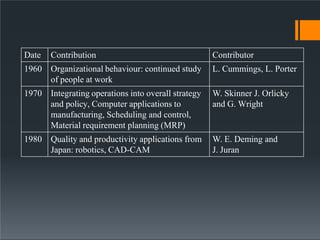

There are eight quality management gurus discussed in the document: W. Edwards Deming, Joseph M. Juran, Philip B. Crosby, Armand Vallin Feigenbaum, Kaoru Ishikawa, David A. Garvin, Shigeo Shingo, and Genichi Taguchi. Each guru made important contributions to total quality management. Deming focused on statistical process control and continuous improvement. Juran emphasized quality planning, control, and improvement. Crosby defined quality as conformance to requirements and introduced the concept of quality costs. Feigenbaum defined total quality management. Ishikawa developed quality control tools like cause-and-effect diagrams. Shingo invented just-in-time manufacturing