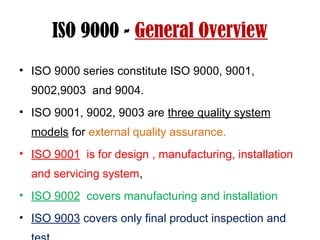

The document provides an overview of ISO 9000 quality management standards. It discusses key aspects of ISO 9000 including its objectives to ensure customer satisfaction, prevent errors, and improve productivity. It also summarizes the prerequisites of a quality system including having a quality policy, management, and system in place. The document then explains the quality loop and various sections of the ISO 9001:2000 standard, addressing elements, management responsibility, and product realization. It concludes by outlining the six-phase strategy to successfully implement a quality management system which includes investigating the current system, analyzing it, designing a new system, developing it, implementing it, and maintaining it.

![ISO 9000 - The Philosophy

• Basically, there are two mindset approaches to ISO 9000 registration.

• First, to view the ISO 9000 series as a set of standards which needs to

be addressed sooner or later.

– This first approach is invariably and primarily motivated by a

commercial/marketing/business set of convictions.]

• The other approach sees the ISO 9000 standards as something more

than just a model for quality assurance.

– This philosophy will more often than not see in ISO 9000 an

opportunity to improve managerial style.

– Most experts speak of ways in which the various ISO 9000 models

can help a company reduce internal cost and/or increase efficiency.](https://image.slidesharecdn.com/iso9000-pvcgmprollno-150703171233-lva1-app6892/85/Iso9000-pvcgmp-roll-no-01-12-320.jpg)