The document discusses the adequacy of 1kV for ESD protection in IoT semiconductor design, outlining the evolution of ESD standards and the challenges faced in modern applications. It analyzes risks based on various IoT applications through case studies, highlighting that while 1kV is generally sufficient under controlled conditions, specific scenarios may require higher levels of protection. The necessity for tailored ESD solutions and the importance of early design phase considerations are emphasized to address evolving threats in diverse operational environments.

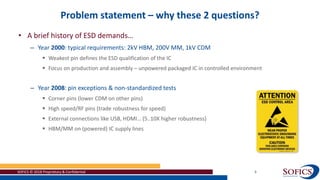

![Risk analysis – ISO 31000

SOFICS © 2018 Proprietary & Confidential 10

• Risk assesment matrix

– Identify threats

– Assess vulnerability

– Determine likelihood

– Determine impact

– Define risk and mitigation

Impact

RISK

Negligible

[1]

Minor

[2]

Serious

[3]

Critical

[4]

Catastrophic

[5]

Likelihood

Extremely

unlikely

[A]

None Trivial Low

Below

moderate

Moderate

Remote

[B]

Trivial Low

Below

moderate

Moderate Tolerable

Occasional

[C]

Low

Below

moderate

Moderate Tolerable Substantial

Reasonably

possible

[D]

Below

moderate

Moderate Tolerable Substantial Major

Frequent

[E]

Moderate Tolerable Substantial Major Intolerable](https://image.slidesharecdn.com/2018-09-27soficsatiotworkshop-slideshare-200227111230/85/IoT-workshop-Is-1kV-Also-Enough-for-IoT-ESD-Protection-Do-Current-Test-Methods-and-Models-Apply-10-320.jpg)

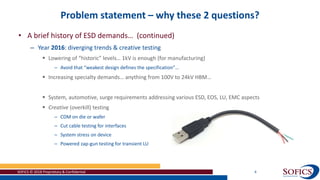

![Risk analysis – adequate protection

SOFICS © 2018 Proprietary & Confidential 15

Impact

RISK Negligible

[1]

Minor

[2]

Serious

[3]

Critical

[4]

Catastrophic

[5]

Likelihood

Extremely

unlikely

[A]

None Trivial Low

Below

moderate

Moderate

Remote

[B]

Trivial Low

Below

moderate

Moderate Tolerable

Occasional

[C]

Low

Below

moderate

Moderate Tolerable Substantial

Reasonably

possible

[D]

Below

moderate

Moderate Tolerable Substantial Major

Frequent

[E]

Moderate Tolerable Substantial Major Intolerable](https://image.slidesharecdn.com/2018-09-27soficsatiotworkshop-slideshare-200227111230/85/IoT-workshop-Is-1kV-Also-Enough-for-IoT-ESD-Protection-Do-Current-Test-Methods-and-Models-Apply-15-320.jpg)

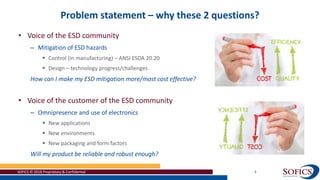

![Case 4: other networked medical devices

SOFICS © 2018 Proprietary & Confidential 26

• Likelihood and impact differ significantly between applications

– Wearable, external devices have higher likelihood of ESD events

– Life supporting devices (pacemakers) have a bigger impact if things go wrong

Impact

RISK [1] [2] [3] [4] [5]

Likelihood

[A]

[B]

[C]

[D]

[E]](https://image.slidesharecdn.com/2018-09-27soficsatiotworkshop-slideshare-200227111230/85/IoT-workshop-Is-1kV-Also-Enough-for-IoT-ESD-Protection-Do-Current-Test-Methods-and-Models-Apply-26-320.jpg)