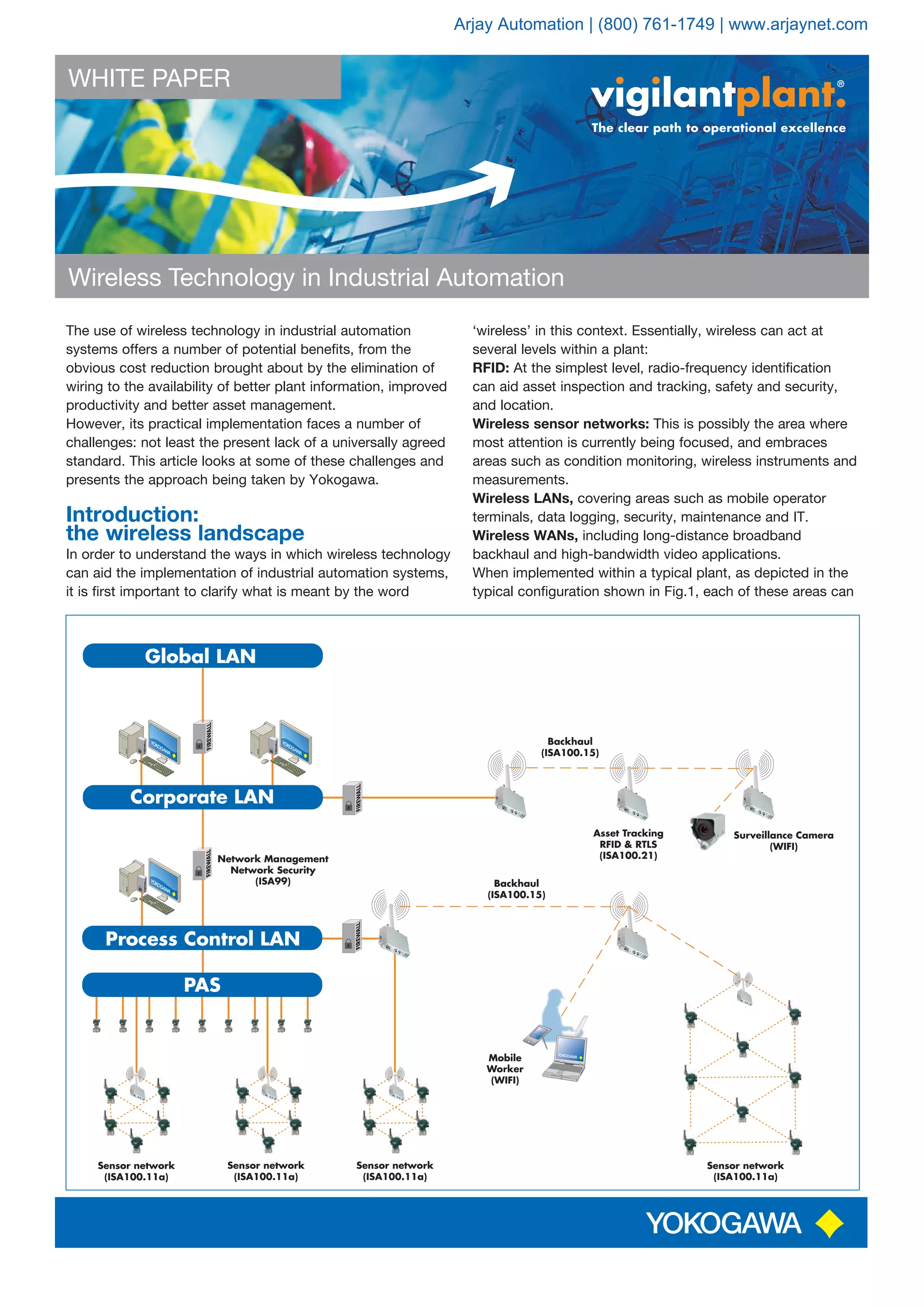

This document discusses the benefits and challenges of implementing wireless technology in industrial automation, highlighting cost reductions, improved productivity, and better asset management through wireless sensor networks. It emphasizes the need for a unified standard, currently complicated by differing protocols like WirelessHART and ISA100.11a, and outlines Yokogawa's commitment to developing secure, efficient wireless solutions based on the ISA100 standard.