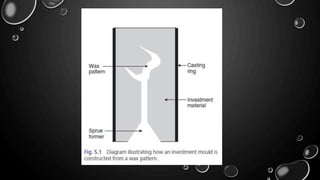

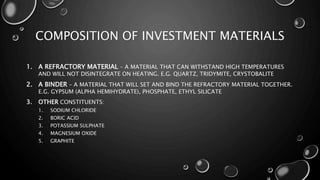

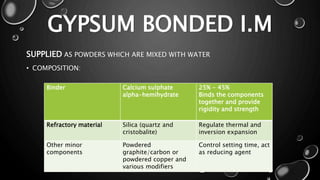

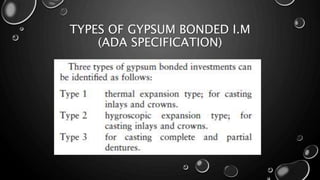

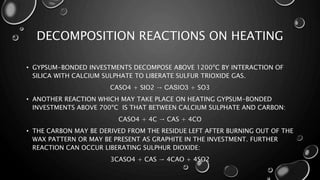

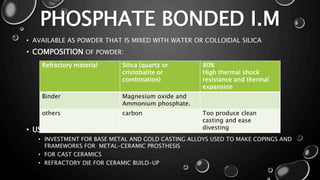

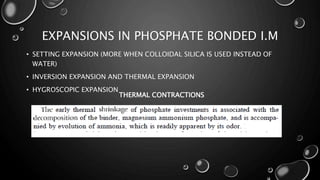

This document provides information on investment materials used for casting dental restorations and appliances. It discusses the requirements, composition, types based on binder, and expansions of different investment materials including gypsum-bonded, phosphate-bonded, and silica-bonded investments. Key points covered include the refractory and binder components of investments, setting and thermal reactions, and how their properties compensate for casting shrinkage. References are provided for further reading on dental materials.