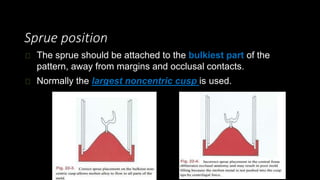

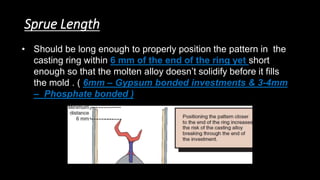

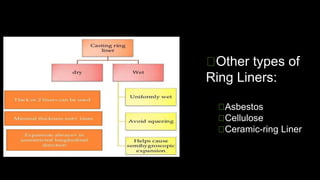

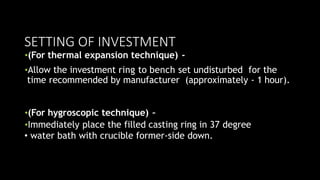

This document provides details on dental casting procedures. It discusses the steps involved, including making a wax pattern, attaching a sprue and crucible former, investing, burnout to remove the wax, casting using various machines to inject molten metal, recovering the casting from the mold, finishing and polishing. Key steps are wax pattern formation, attaching the pattern to a sprue and crucible, investing in refractory material, burning out the wax, melting and injecting dental alloys using different casting methods, and finalizing the surface.