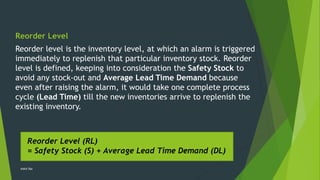

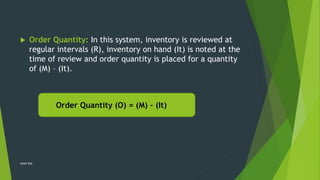

The document discusses inventory models, specifically the fixed reorder quantity system and the fixed reorder period system, which help businesses optimize inventory levels and manage ordering processes. It explains key concepts such as reorder level, safety stock, and order quantity, along with formulas for calculating these metrics. Examples illustrate how to determine order quantities and manage inventory effectively based on demand and lead times.