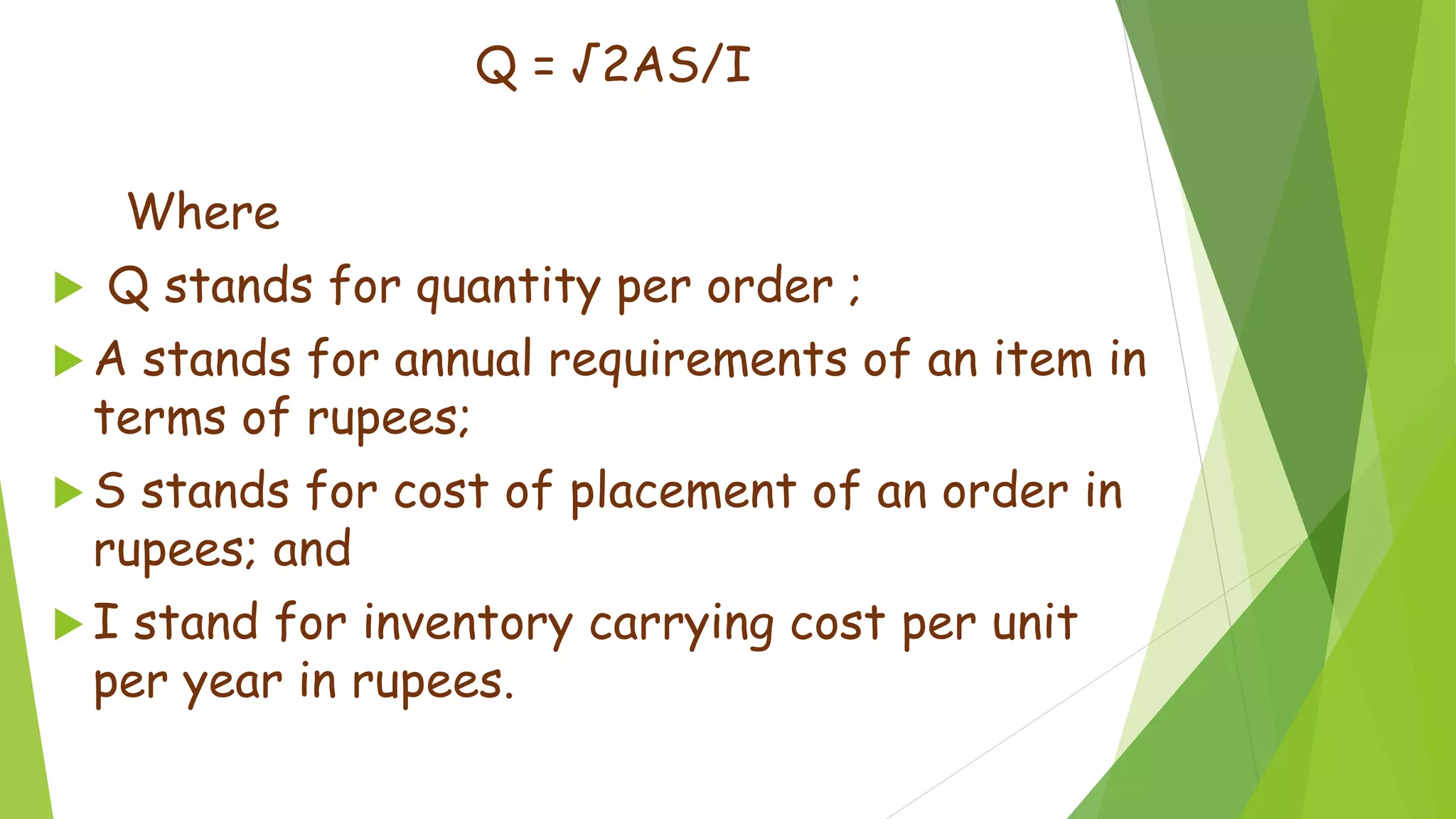

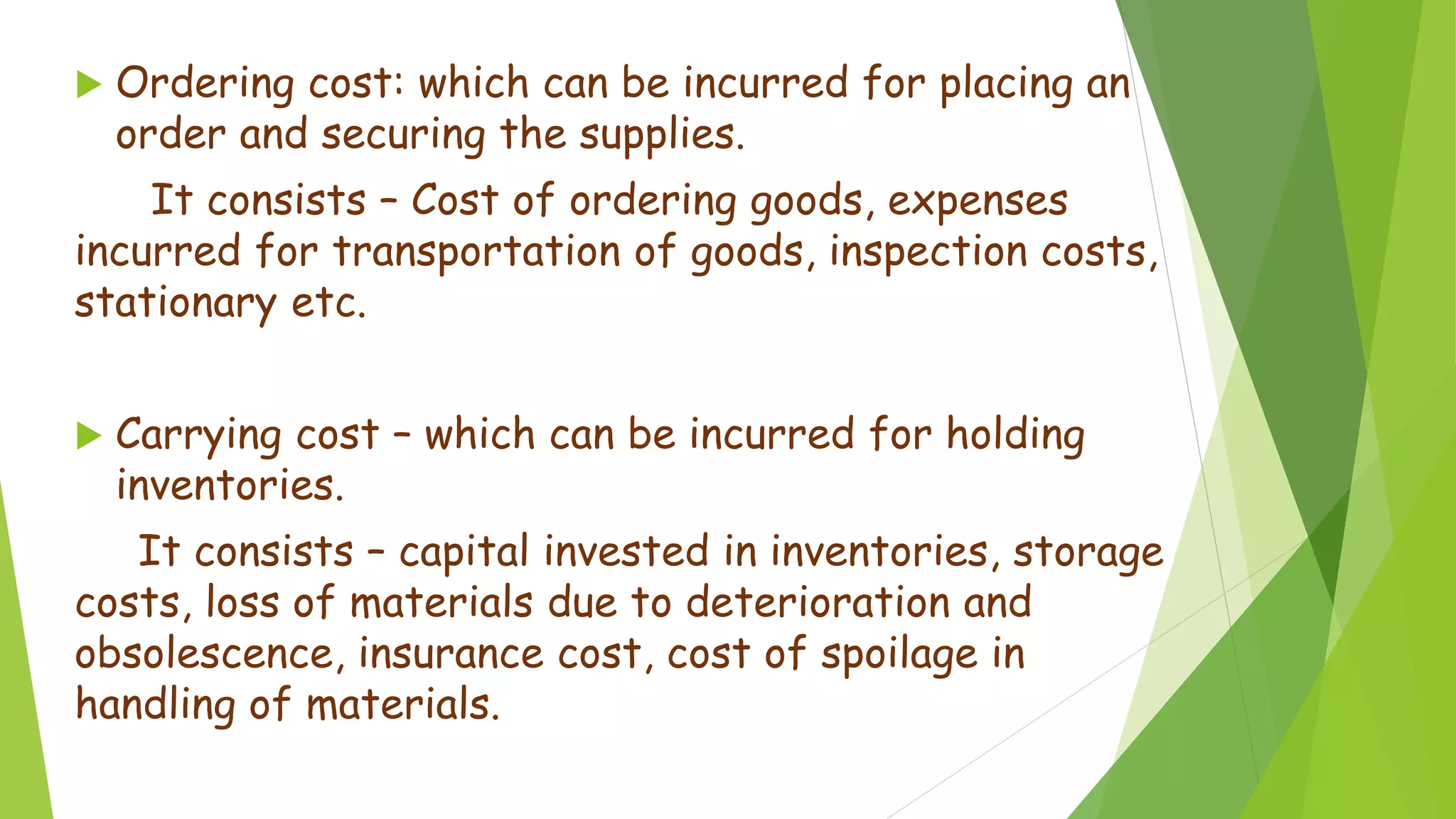

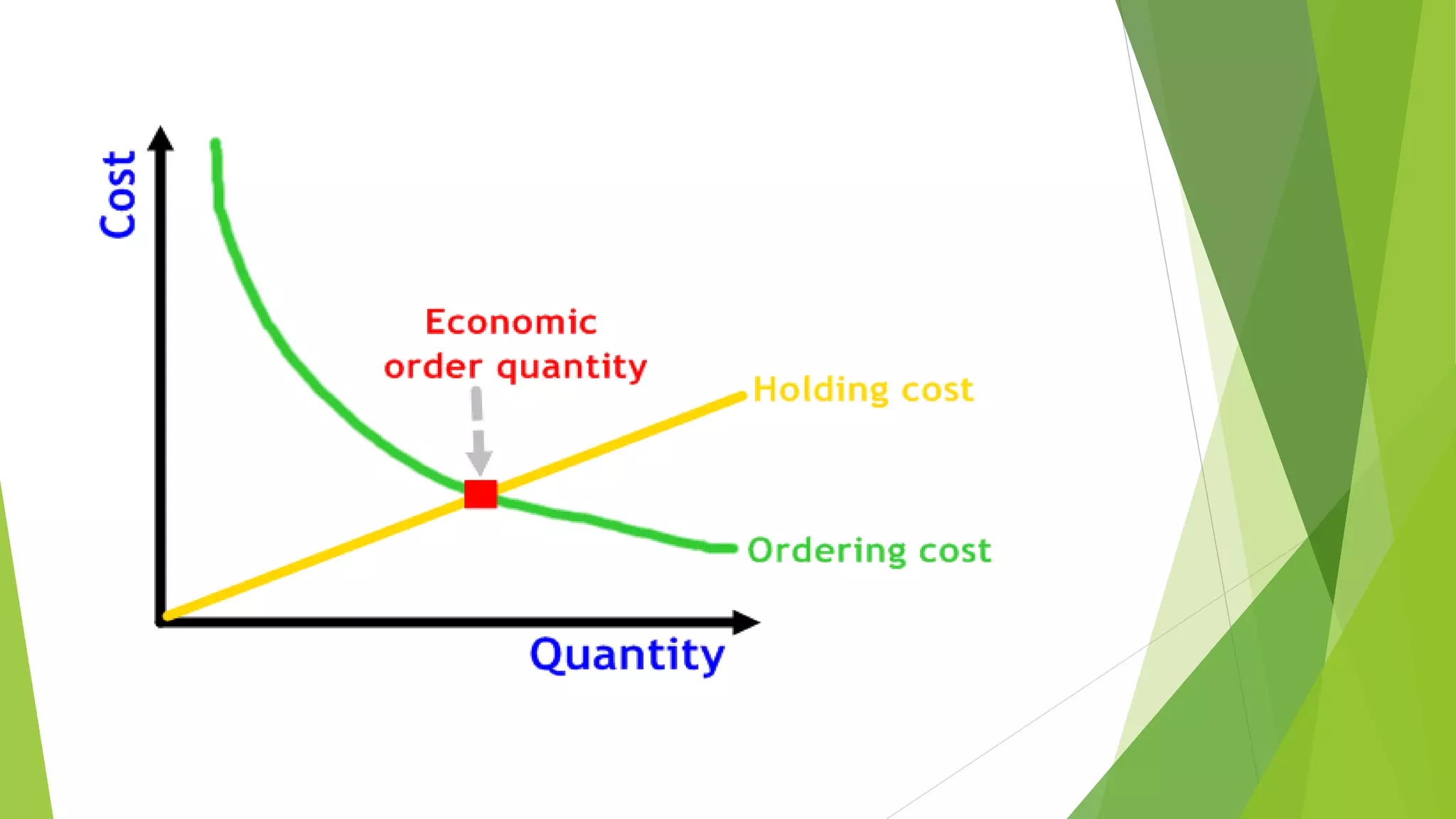

Inventory management involves controlling the ordering, storage, and use of components and finished goods. It represents a major investment for businesses. [1] Techniques for effective inventory management include determining stock levels like reordering levels and minimum/maximum amounts based on consumption rates and lead times. [2] Safety stocks are amounts held above requirements to prevent stock-outs during lead times. [3] Economic order quantity models determine optimal order sizes by balancing ordering and carrying costs.