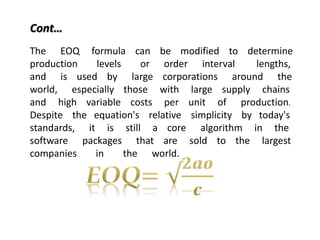

The document discusses inventory management systems and their importance in automating order fulfillment processes, exemplified by just-in-time (JIT) manufacturing strategies that minimize inventory costs. It highlights various inventory classification methods like VED analysis for critical parts and ABC classification based on consumption value, as well as Activity-Based Costing (ABC) to allocate indirect costs to products. Overall, the document emphasizes the significance of efficient inventory management in manufacturing and logistics.