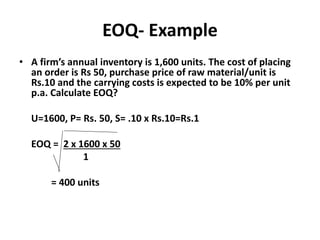

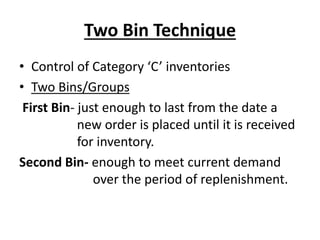

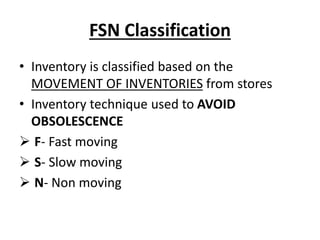

The document outlines inventory management, detailing its definition, objectives, costs, and techniques. Key methods include ABC analysis, Economic Ordering Quantity (EOQ), and Just-In-Time (JIT) inventory control, which aim to minimize costs while meeting product demand. It emphasizes the importance of managing various inventory classifications to optimize stock levels and reduce risks of obsolescence.