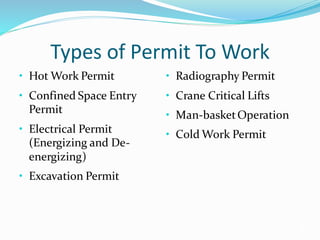

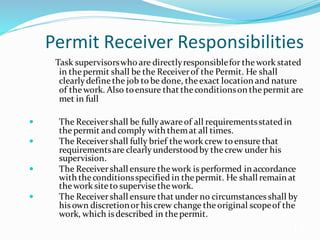

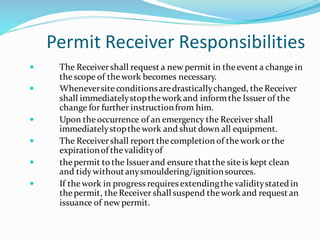

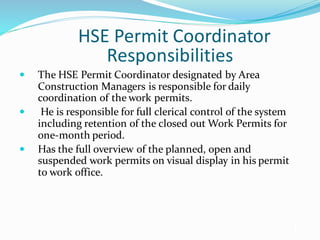

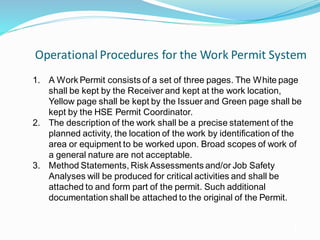

The Permit to Work (PTW) system is a formal procedure used in construction to manage access and activities, ensuring personnel safety and equipment protection. It involves various types of work permits—such as hot work, confined space, and electrical permits—each with specific safety conditions and requirements. Responsibilities are divided among permit issuers, receivers, and coordinators, all ensuring that work is conducted safely and in compliance with established protocols.