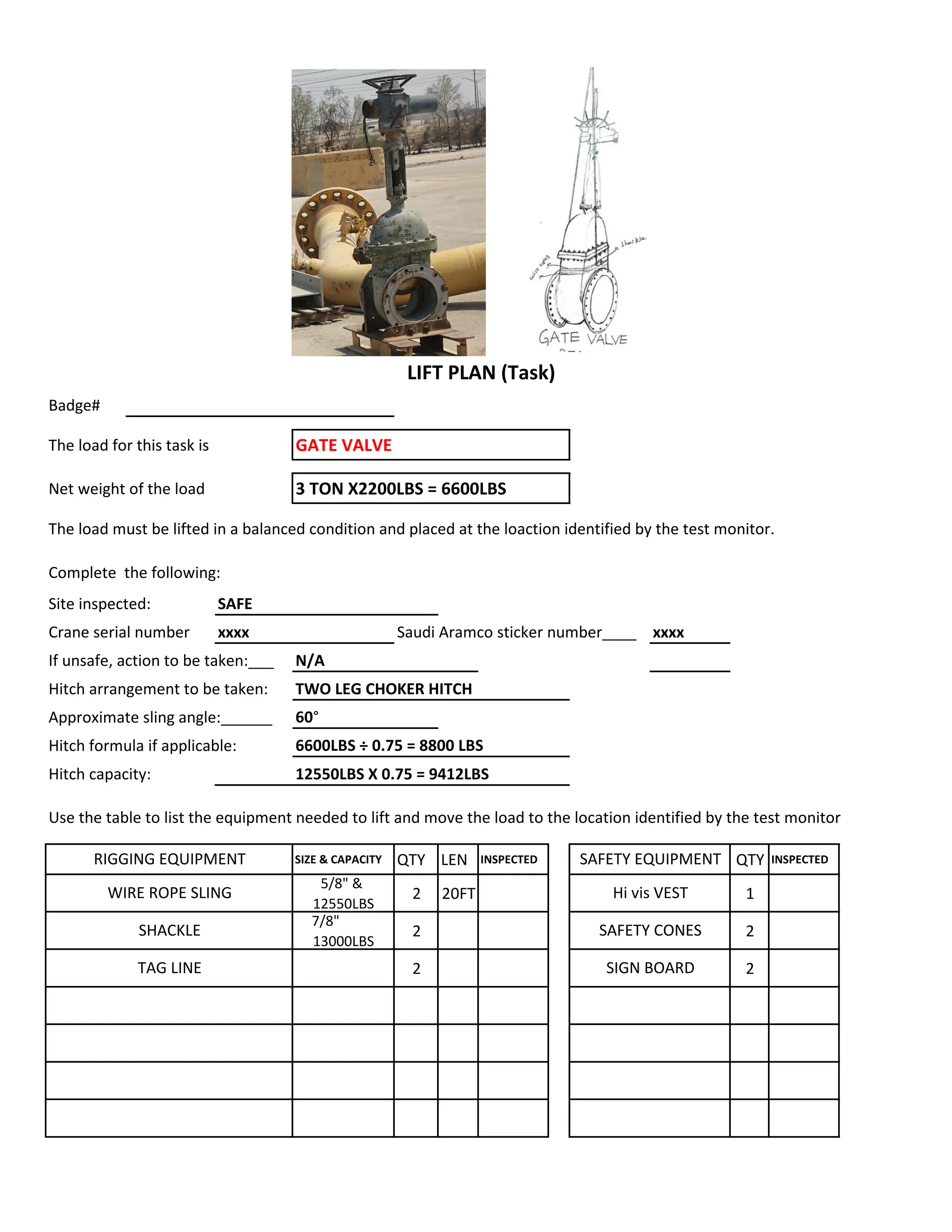

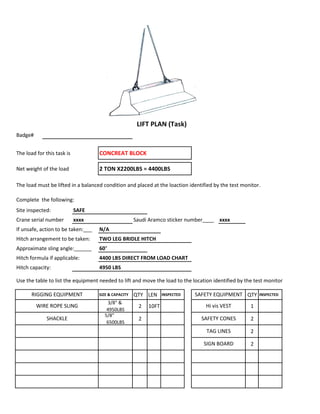

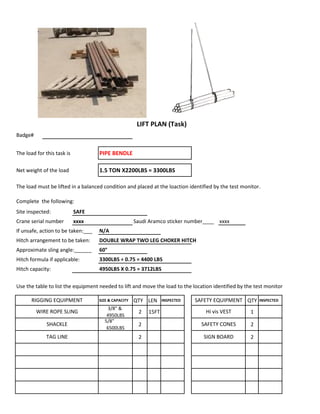

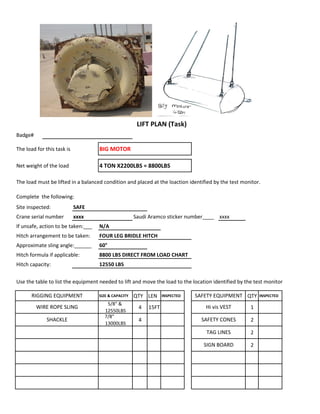

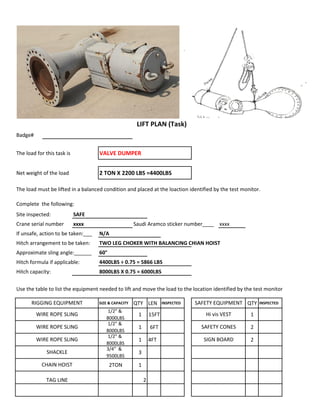

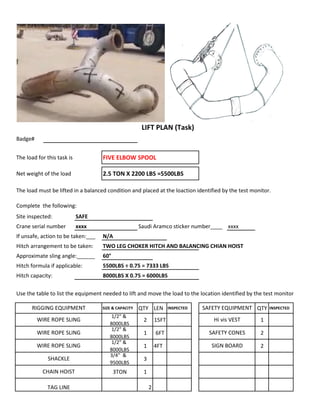

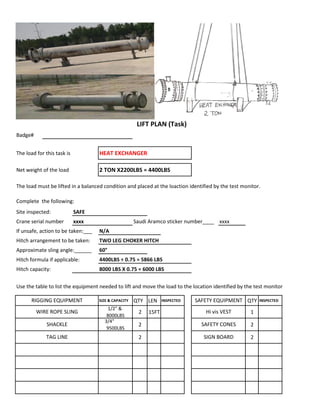

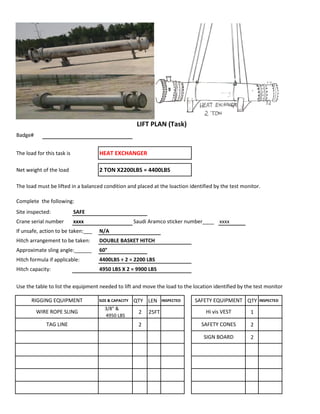

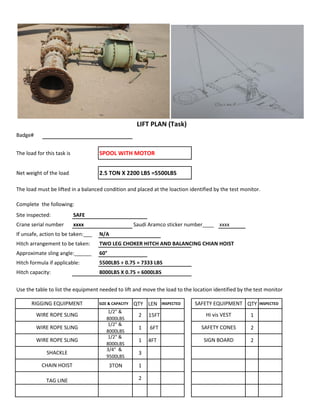

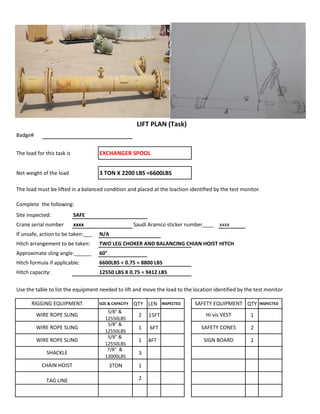

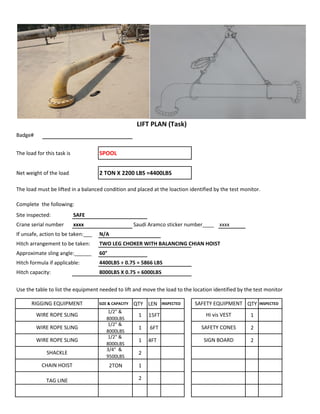

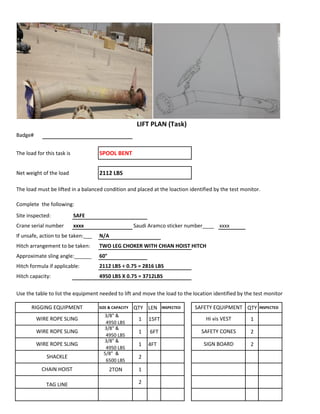

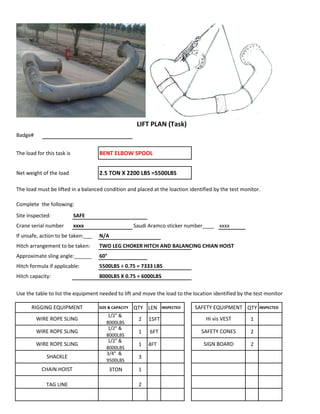

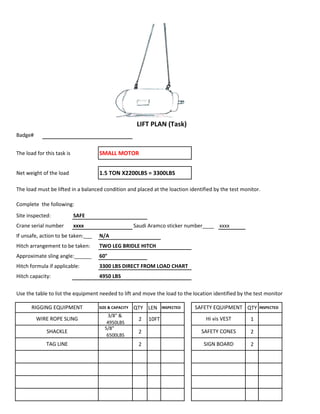

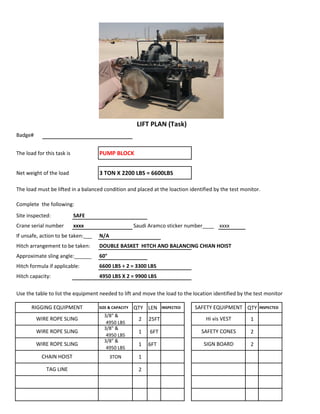

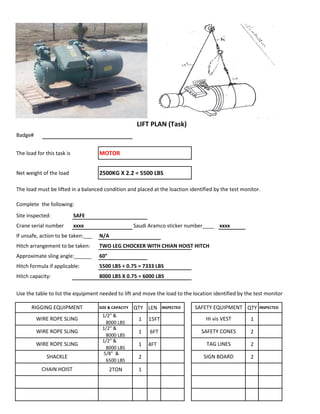

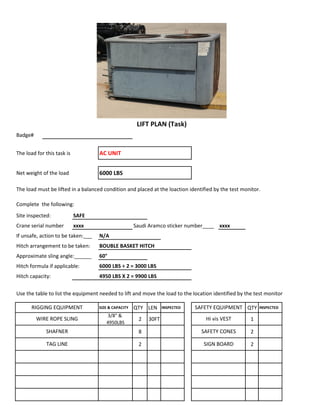

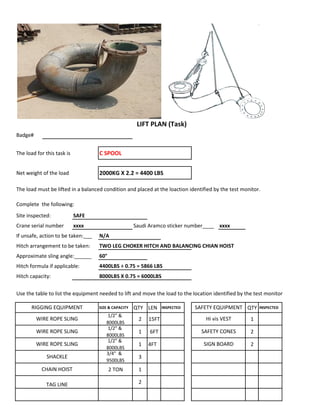

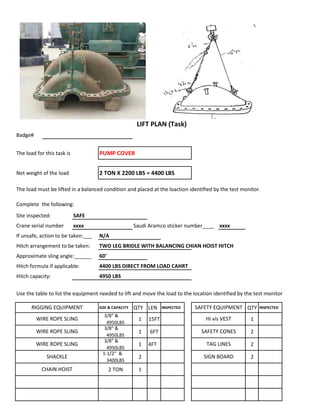

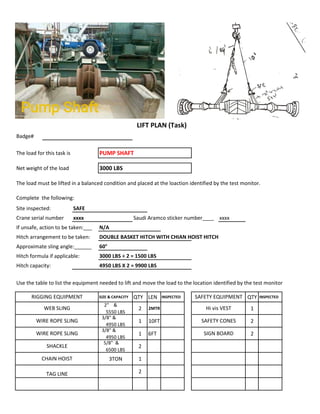

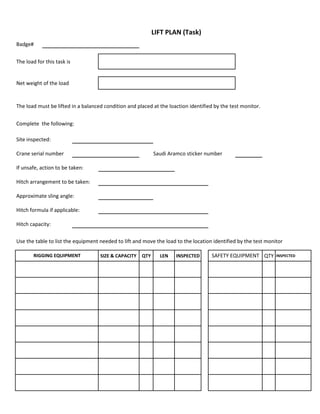

The document contains lifting plans for various loads, including a gate valve, concrete block, pipe bundle, big motor, valve dumper, five elbow spool, heat exchanger, and spool. For each load, the net weight is provided along with the required hitch arrangement, sling angle, hitch capacity calculation, and equipment needed such as wire rope slings, shackles, and safety equipment. The load must be lifted in a balanced condition and placed at the location identified by the test monitor.