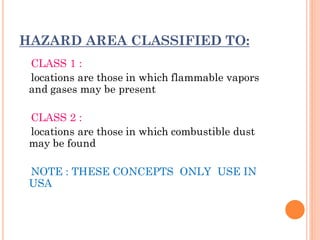

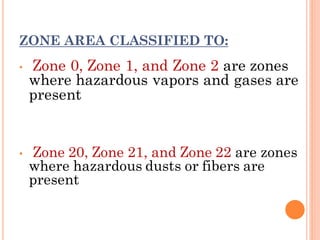

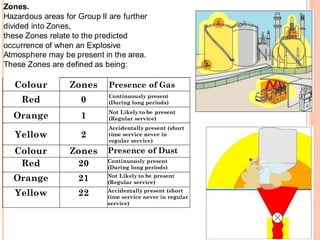

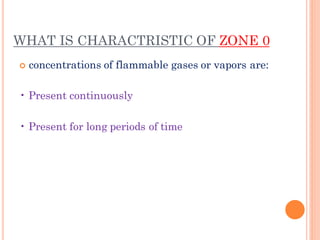

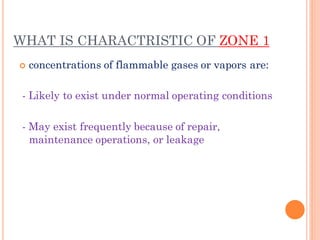

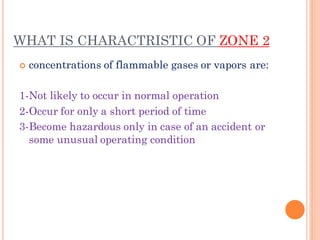

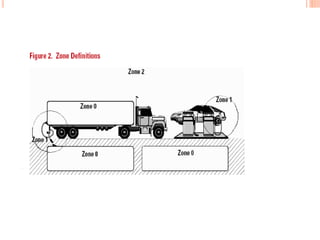

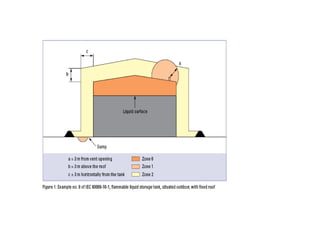

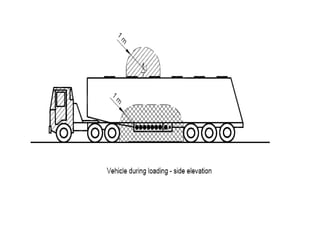

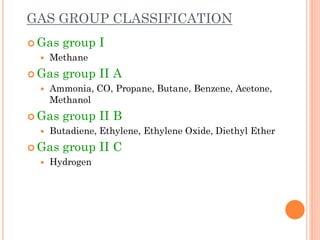

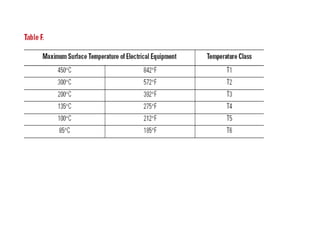

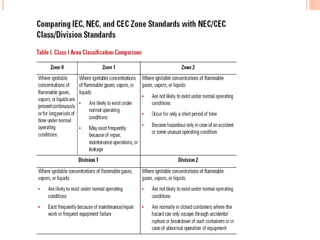

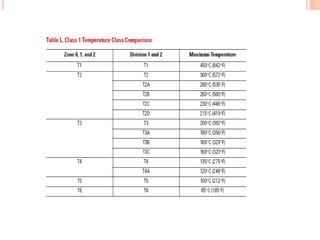

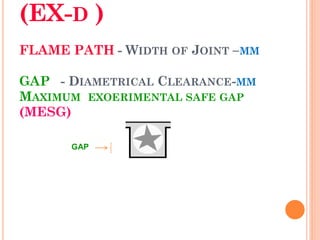

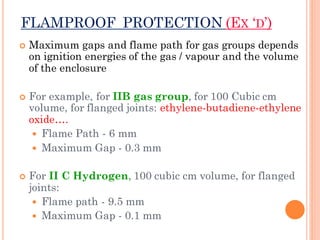

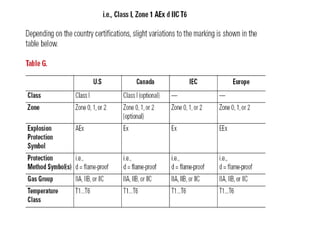

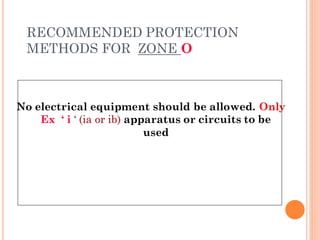

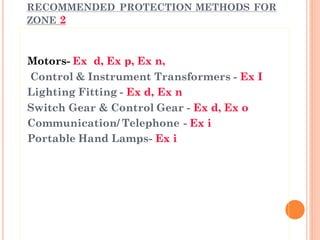

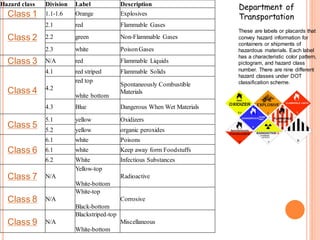

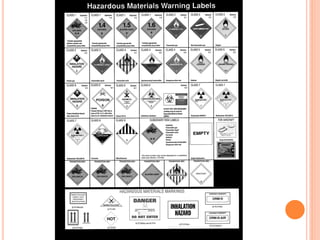

The document outlines classifications for hazardous locations, detailing class and zone designations for areas where flammable gases, vapors, or combustible dust may be present. Specific protection methods for electrical equipment in these areas are provided, including flameproof and intrinsically safe measures. Additionally, it describes various hazard classes and their corresponding labels used for transporting hazardous materials.