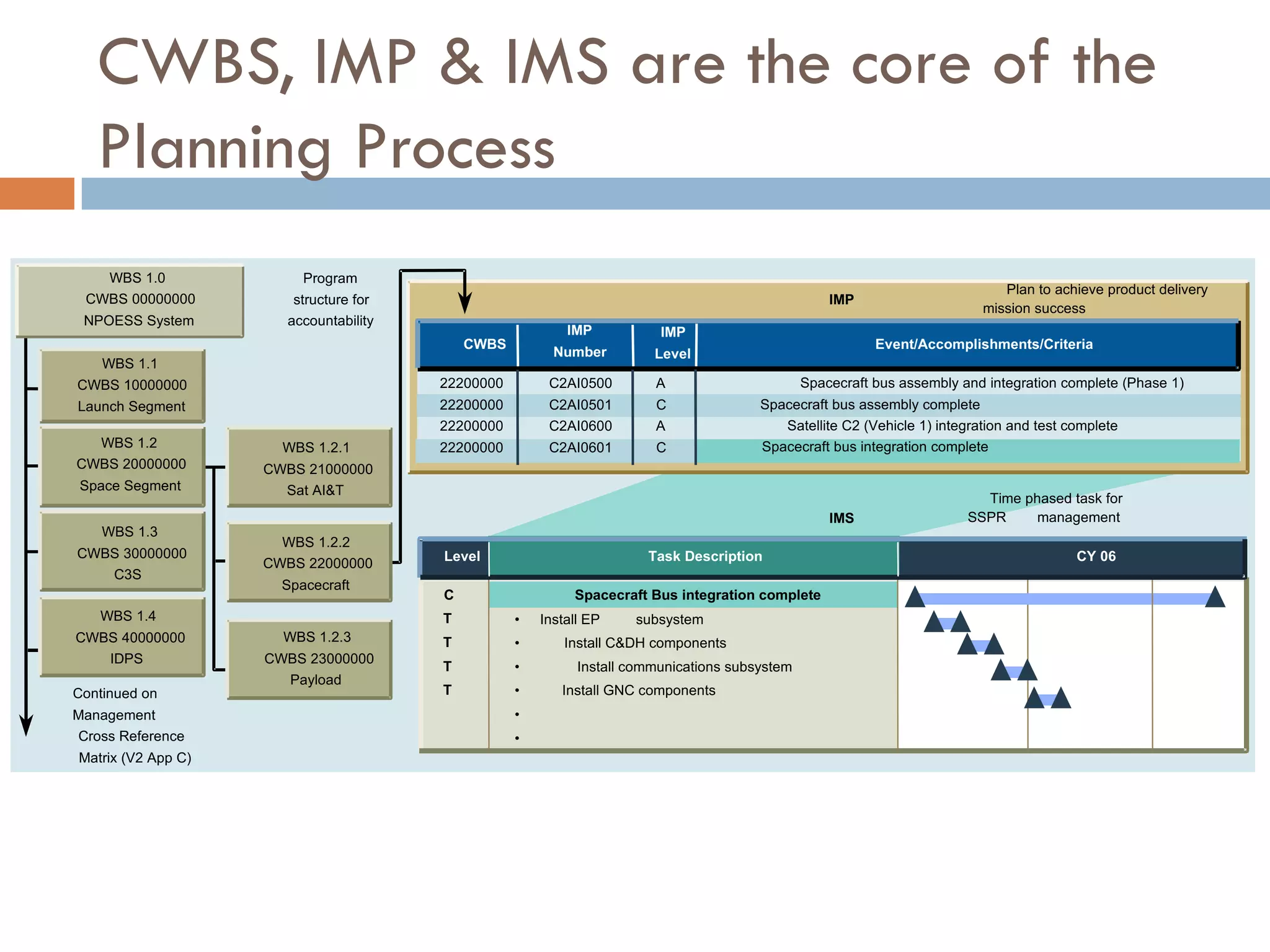

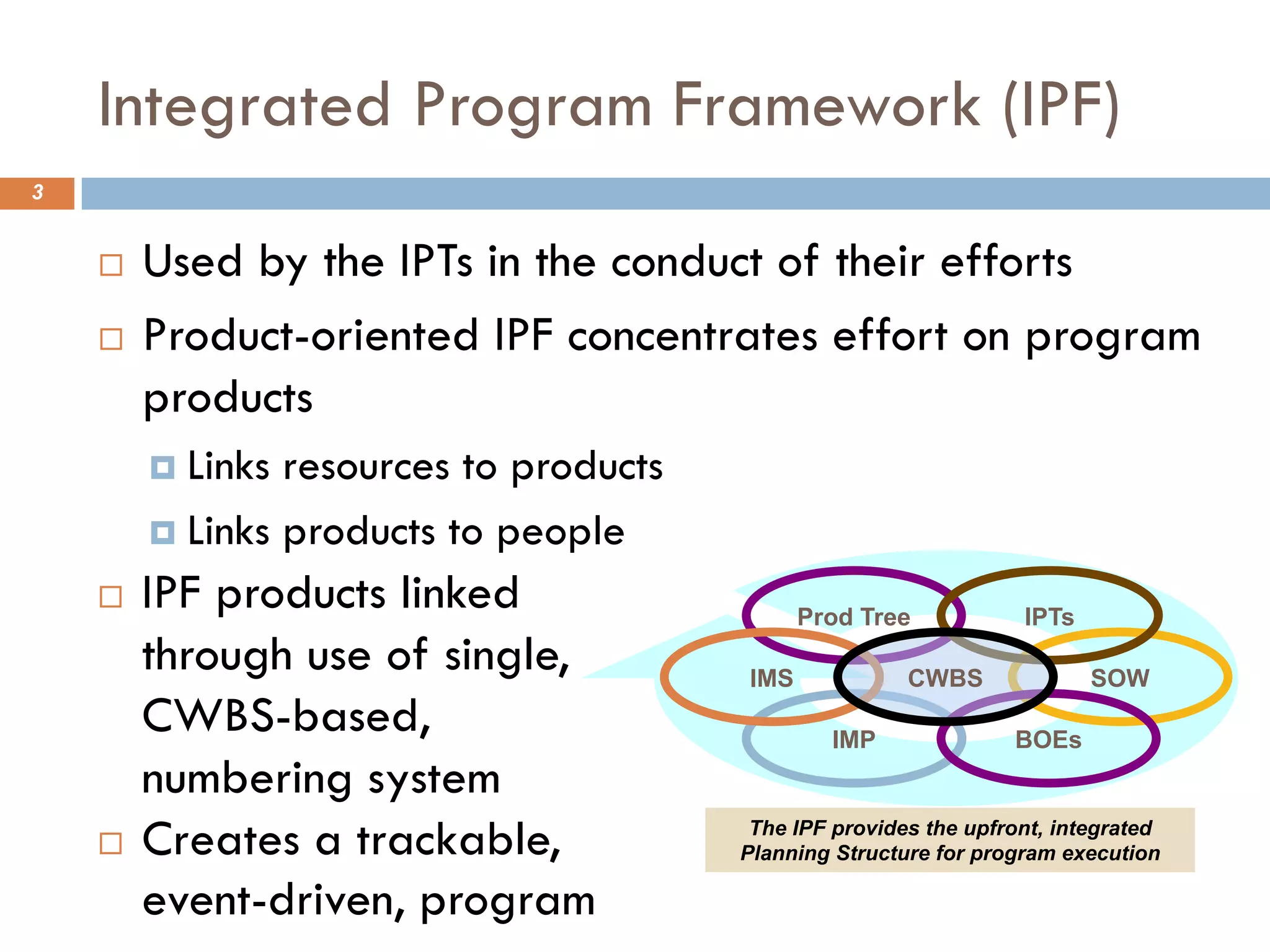

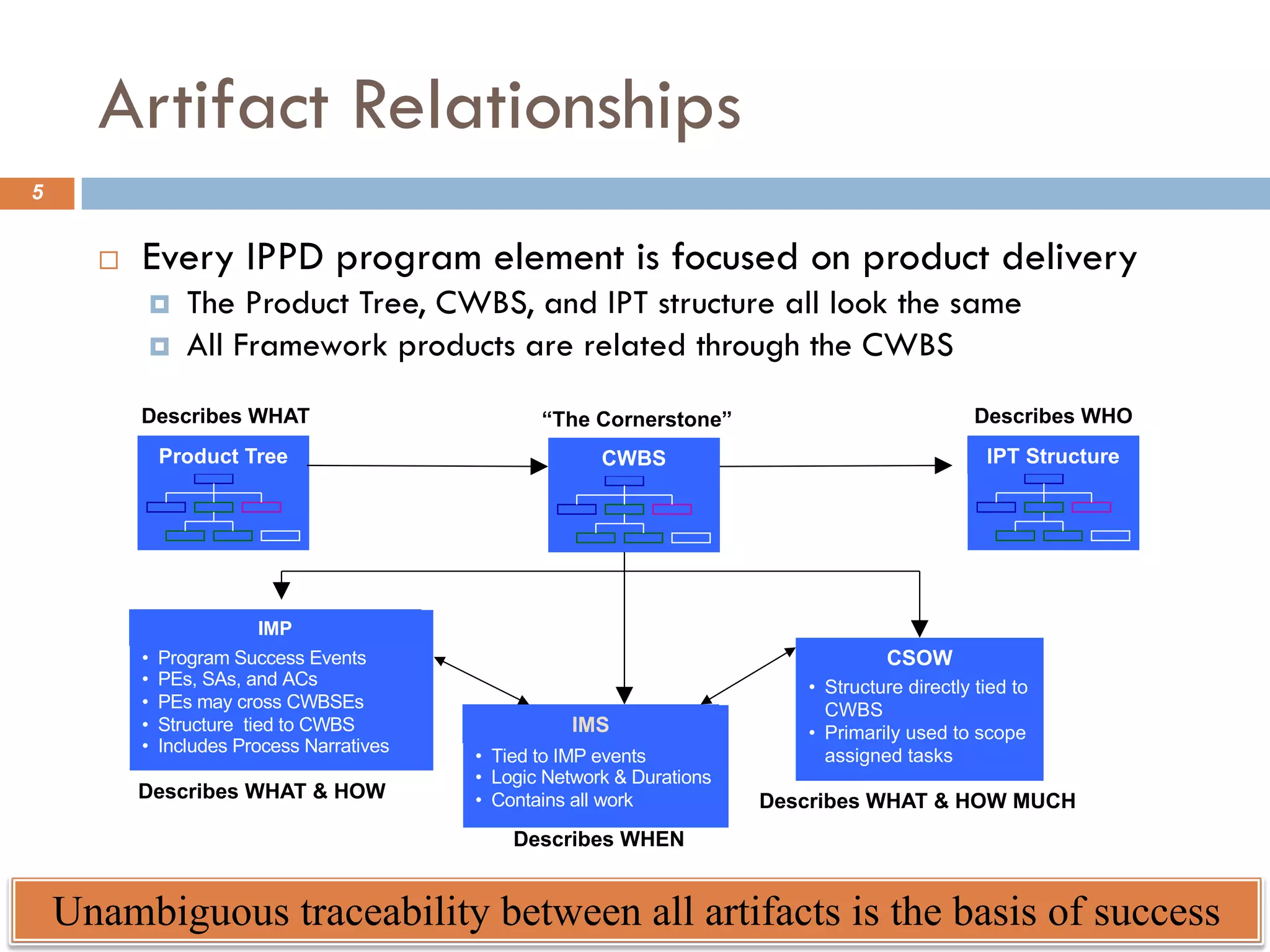

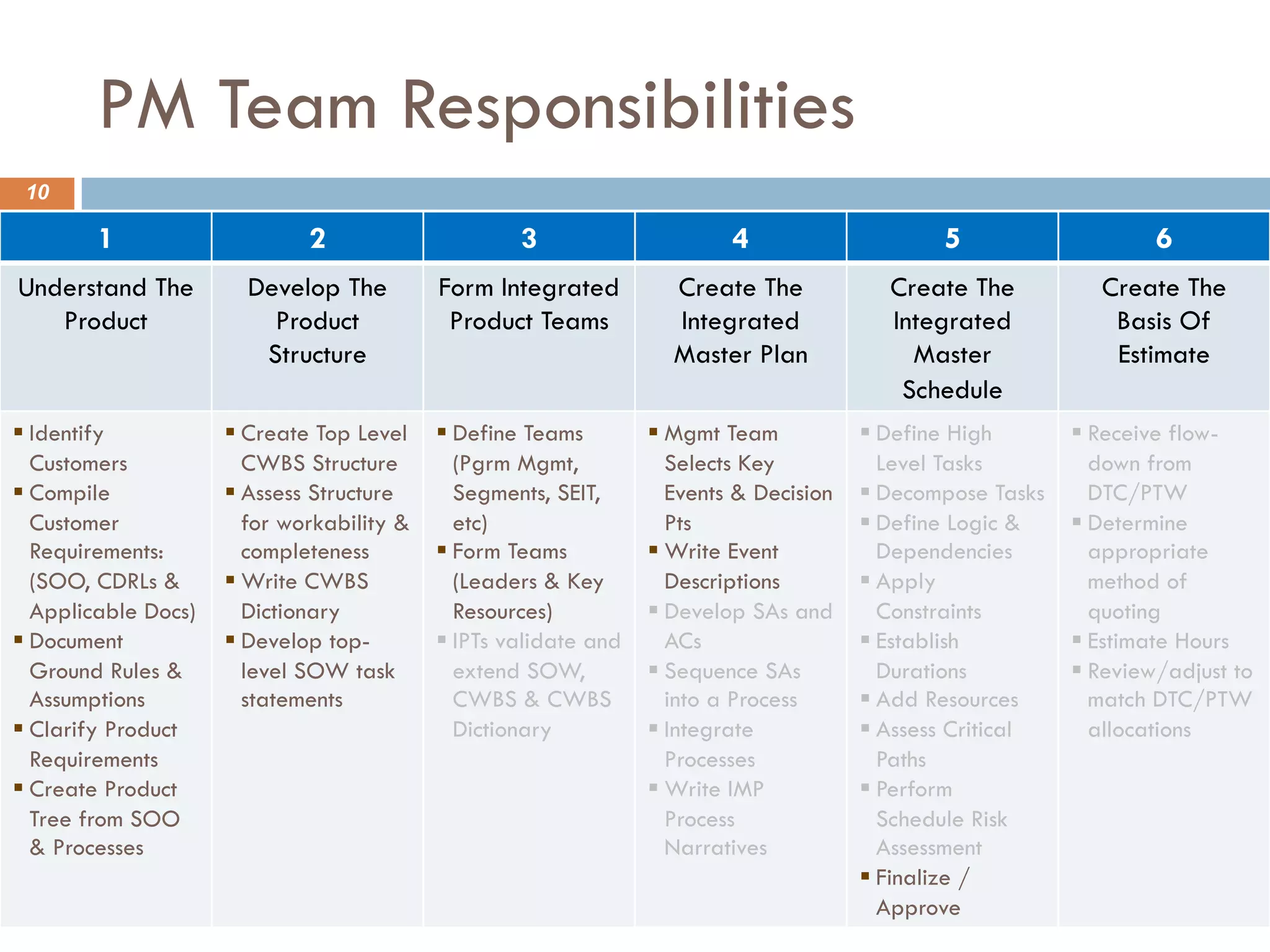

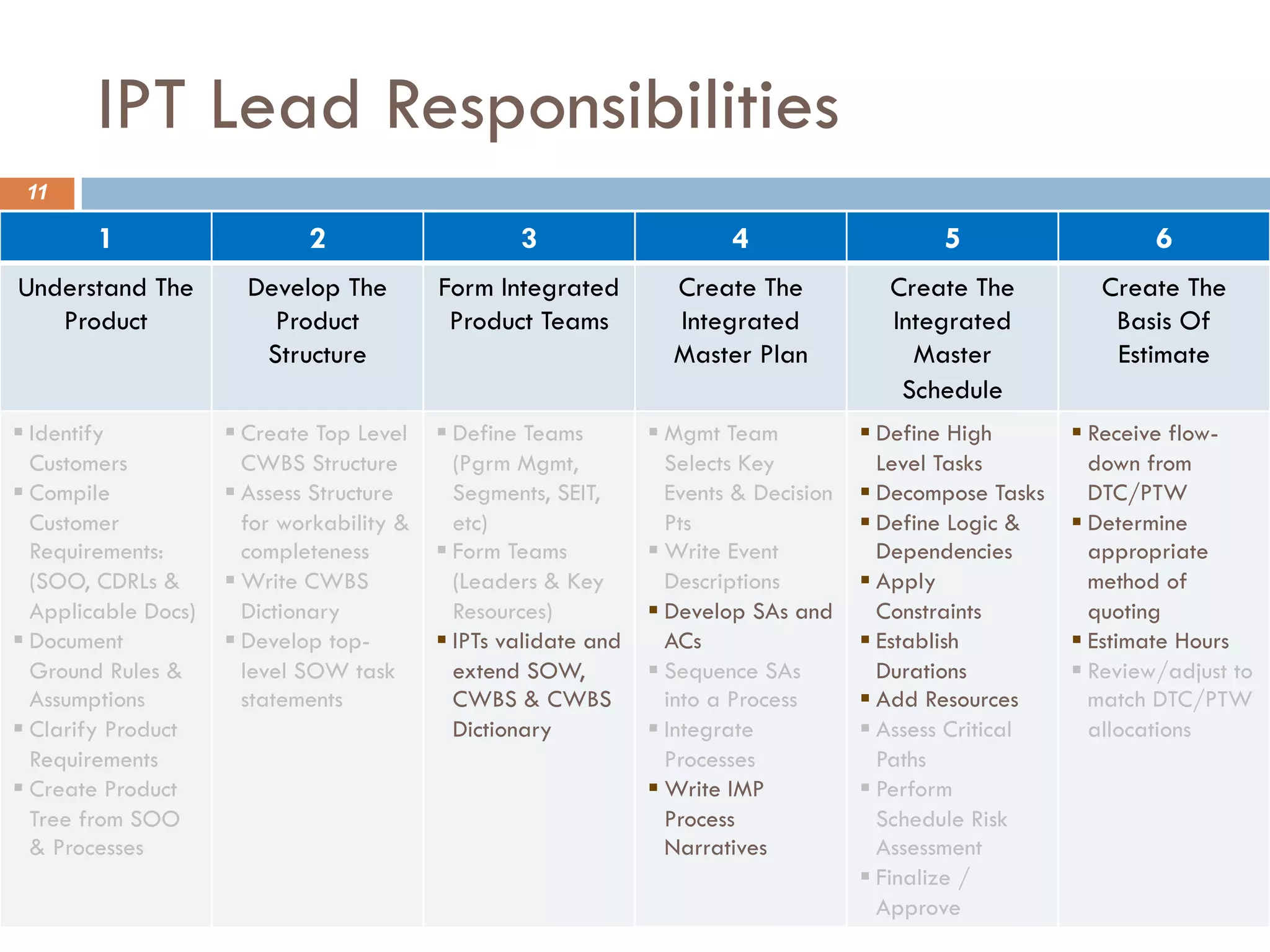

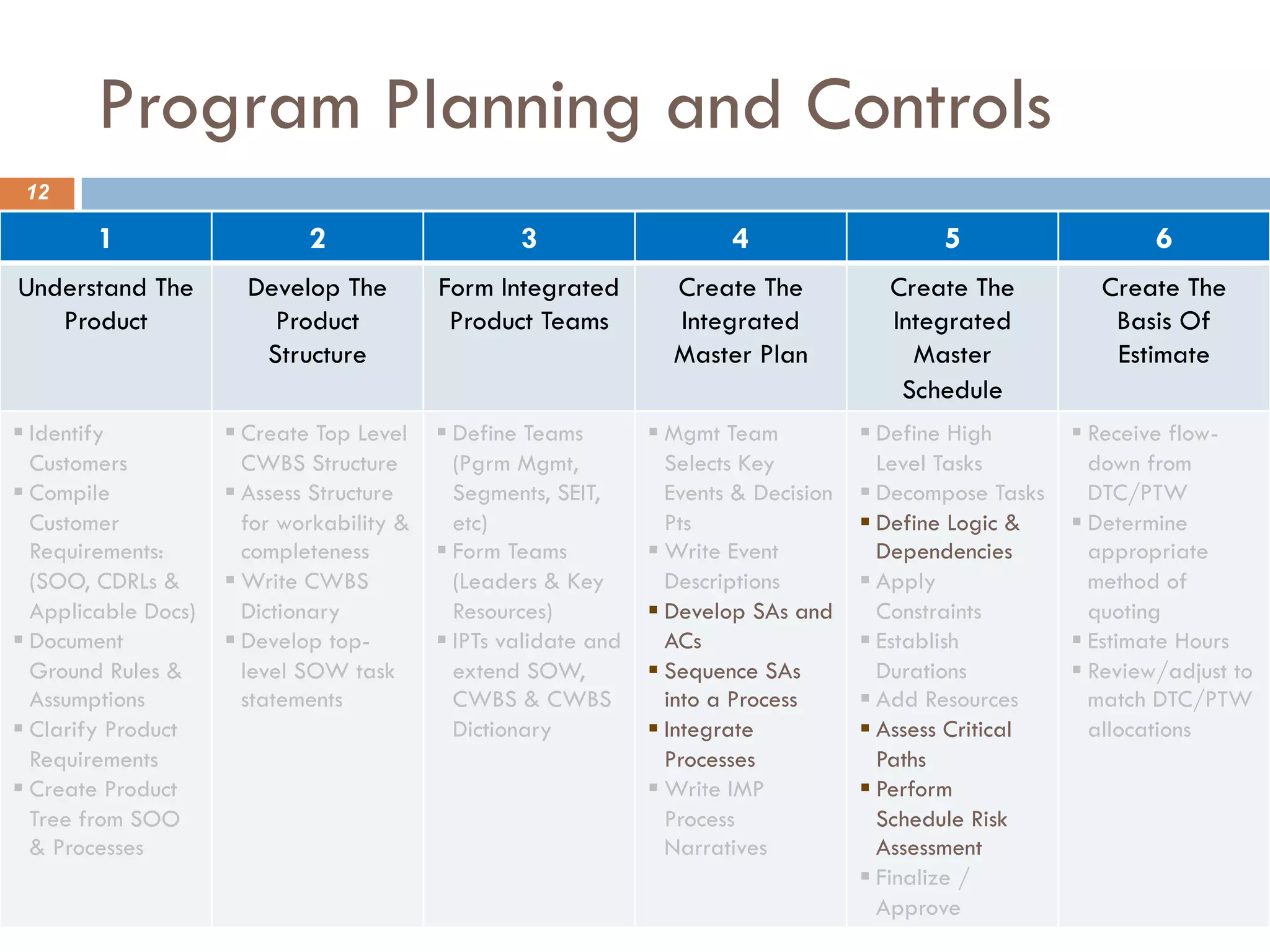

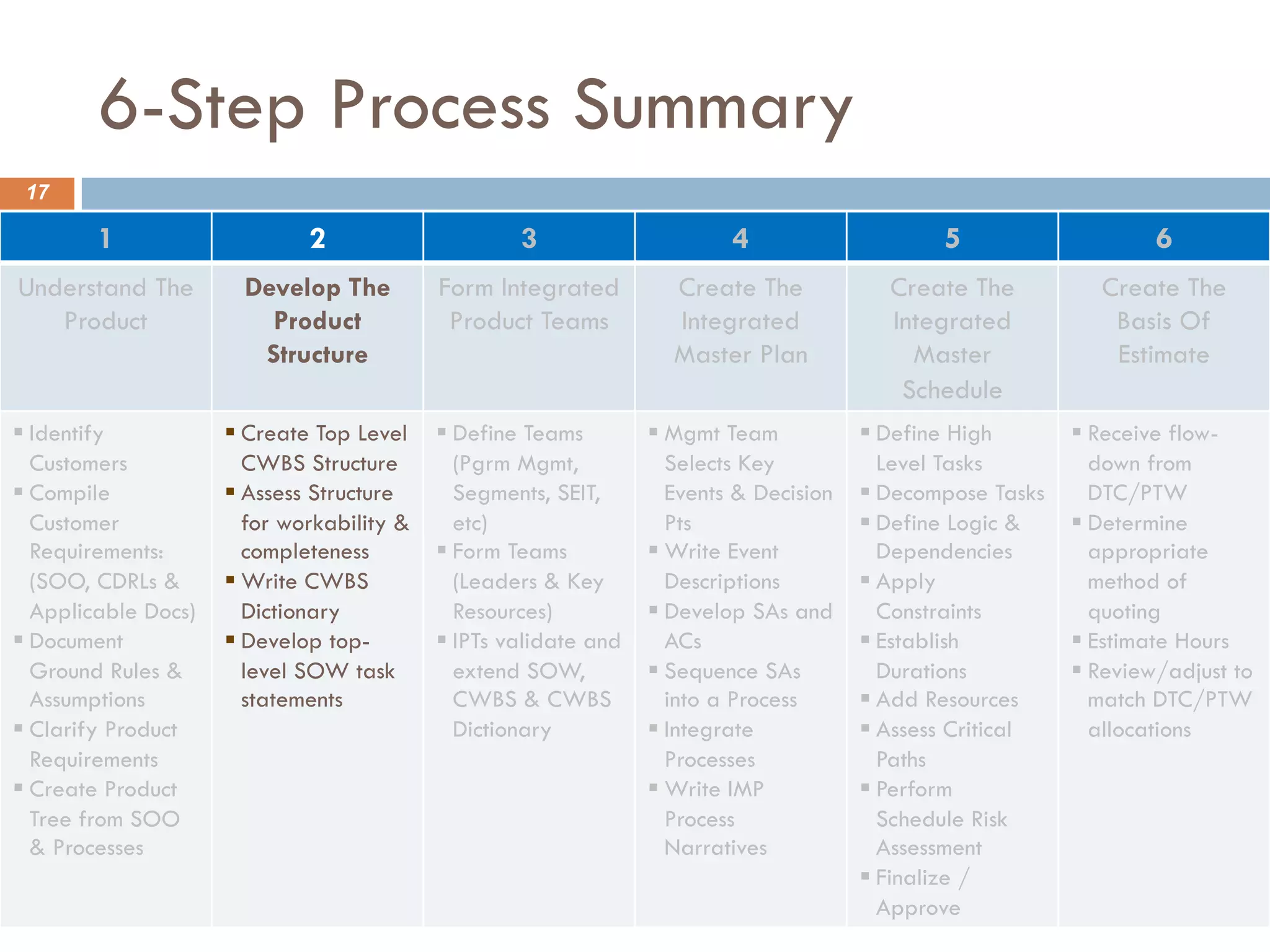

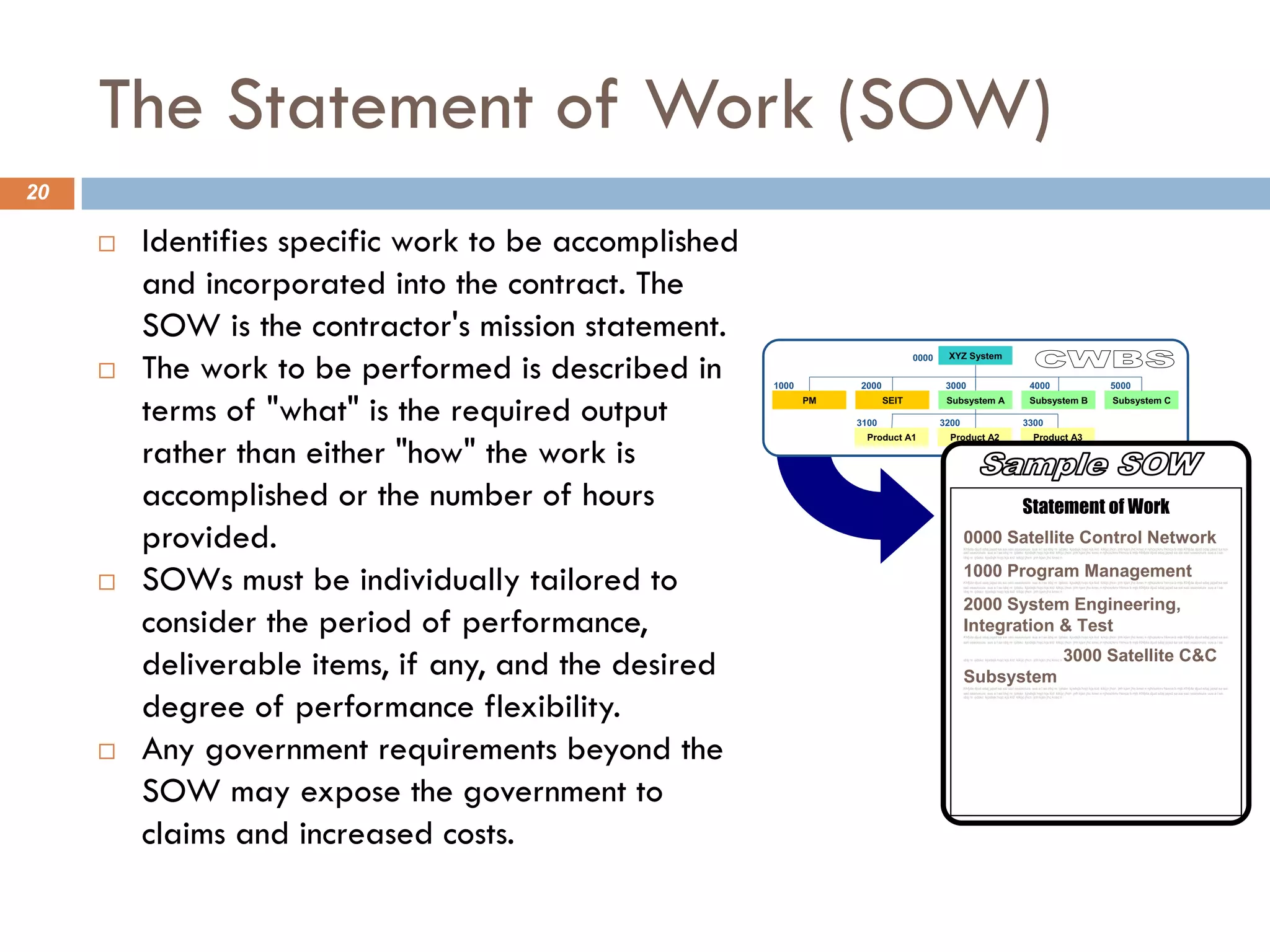

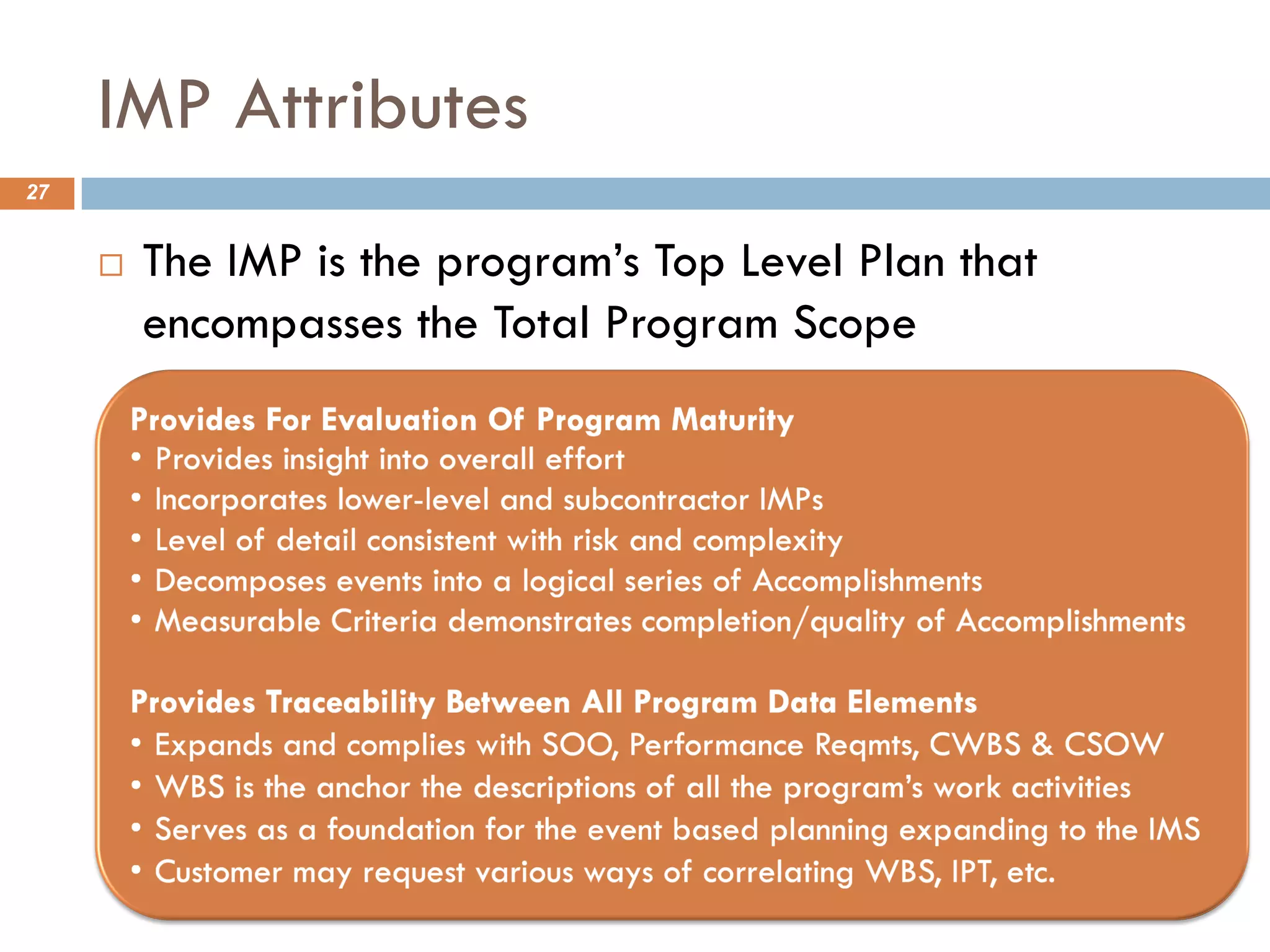

The document discusses the development of an Integrated Master Plan (IMP) as the basis for an Integrated Master Schedule (IMS) for a program. It outlines a 6-step process for developing the IMP and IMS that includes understanding requirements, developing a product structure, forming integrated product teams, creating the IMP, creating the IMS, and developing the basis of estimate. It describes artifacts like the product tree, work breakdown structure, statement of work, and their relationships. It also outlines responsibilities of the program management team, integrated product team leads, and program planning and controls.

![What Makes a Good Program Event ?

34

Some Criteria For Establishing Program / Product

Events:

¨ Customer Provided Events.

¨ Key Decisions Needed. [e.g., down-select of

competitive developments; choosing a key

implementation, such as ion thrusters vs. liquid

propulsion]

¨ Risk Mitigation Event. [e.g., completion of a critical

payload qualification].](https://image.slidesharecdn.com/cevssrcimptrainingnewformat-210302222304/75/Integrated-Master-Plan-Development-34-2048.jpg)