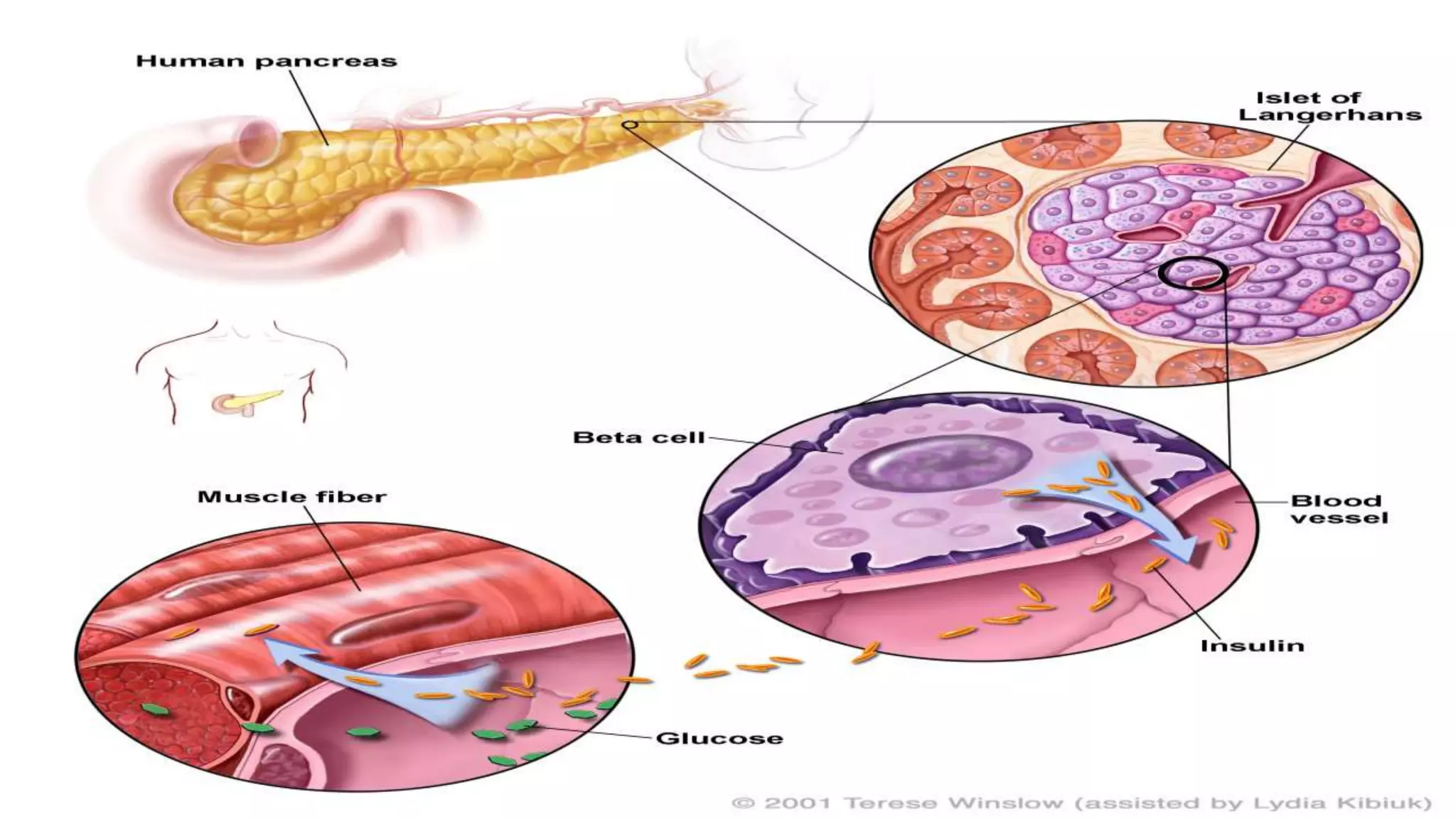

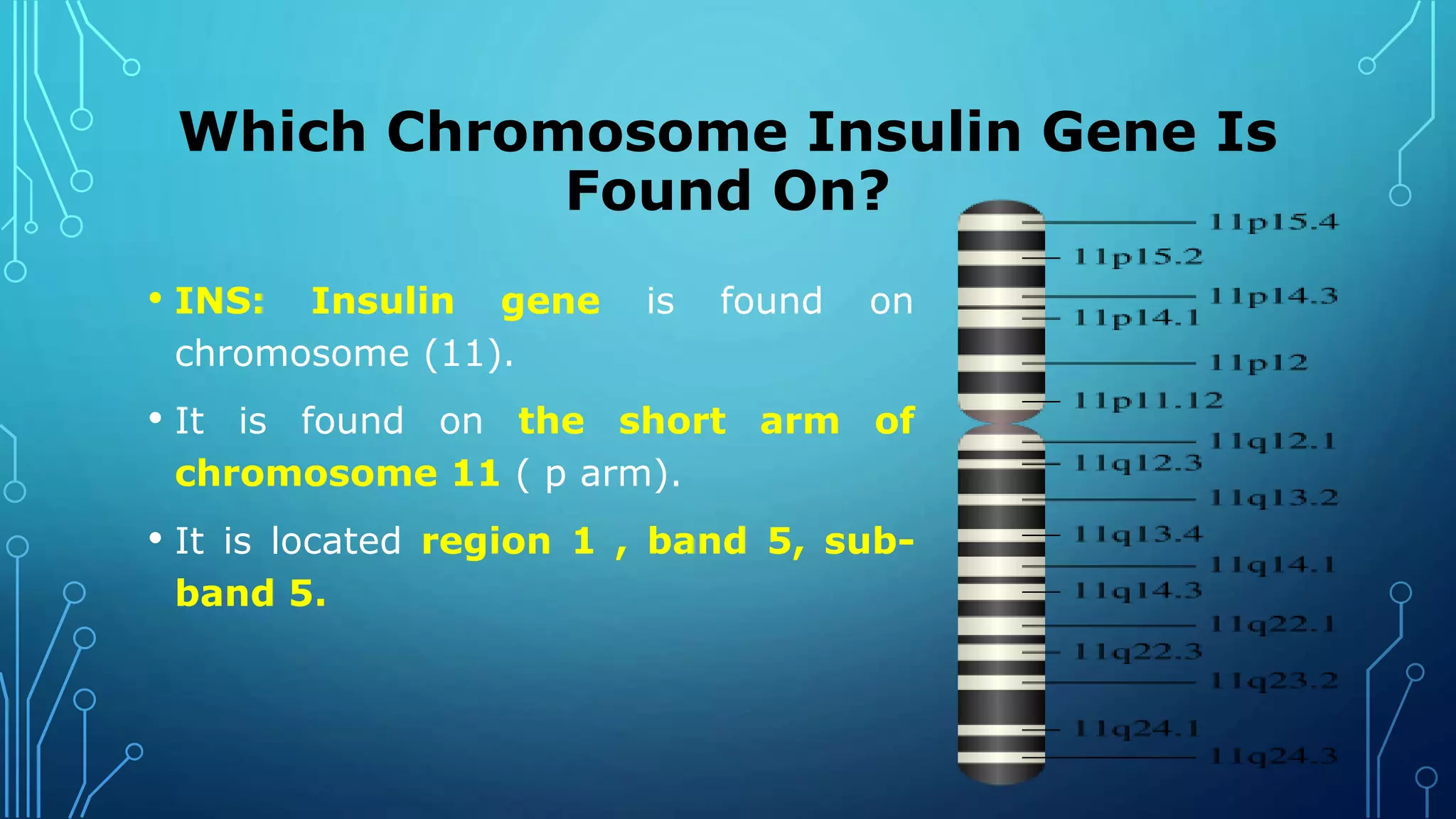

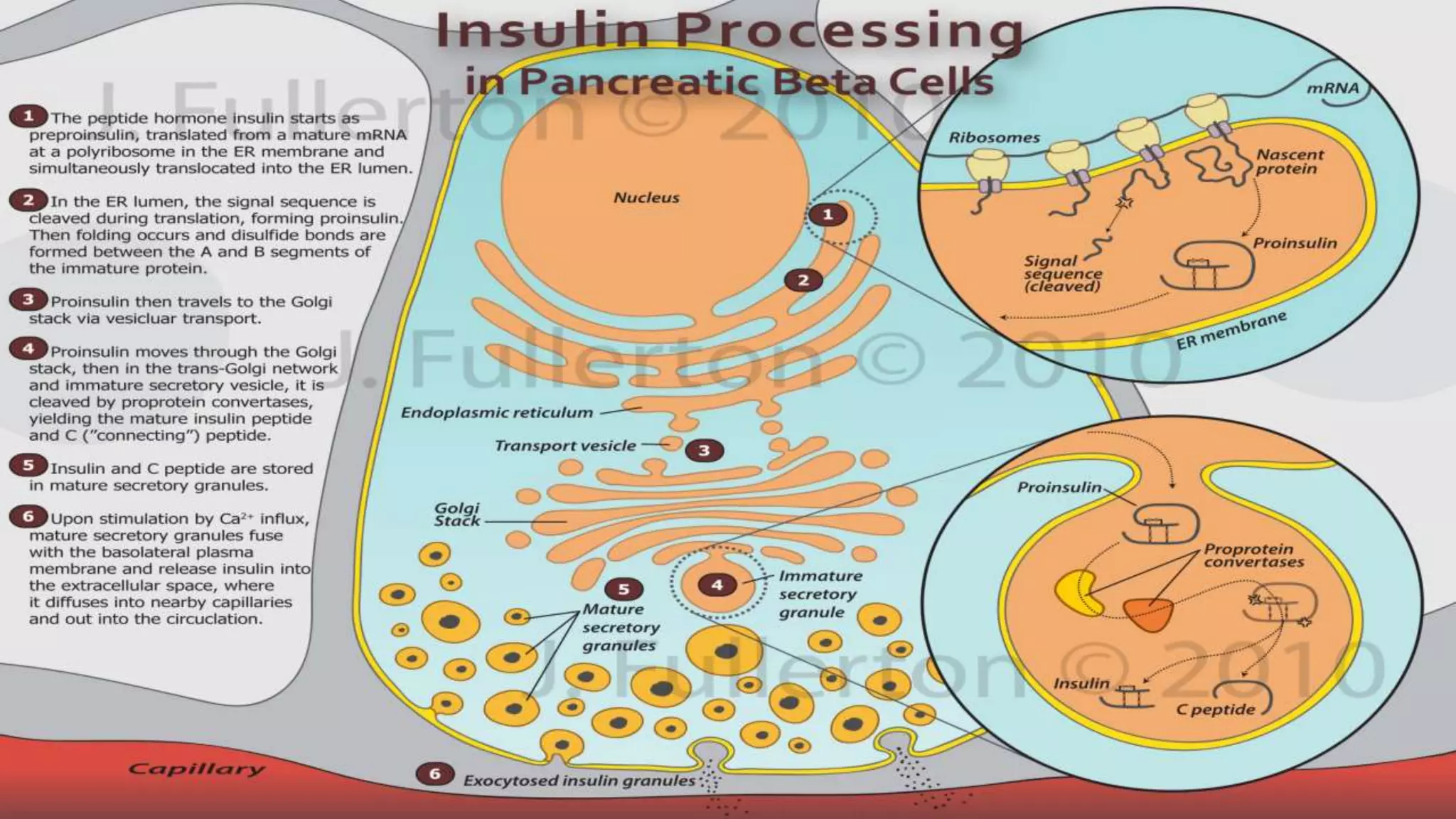

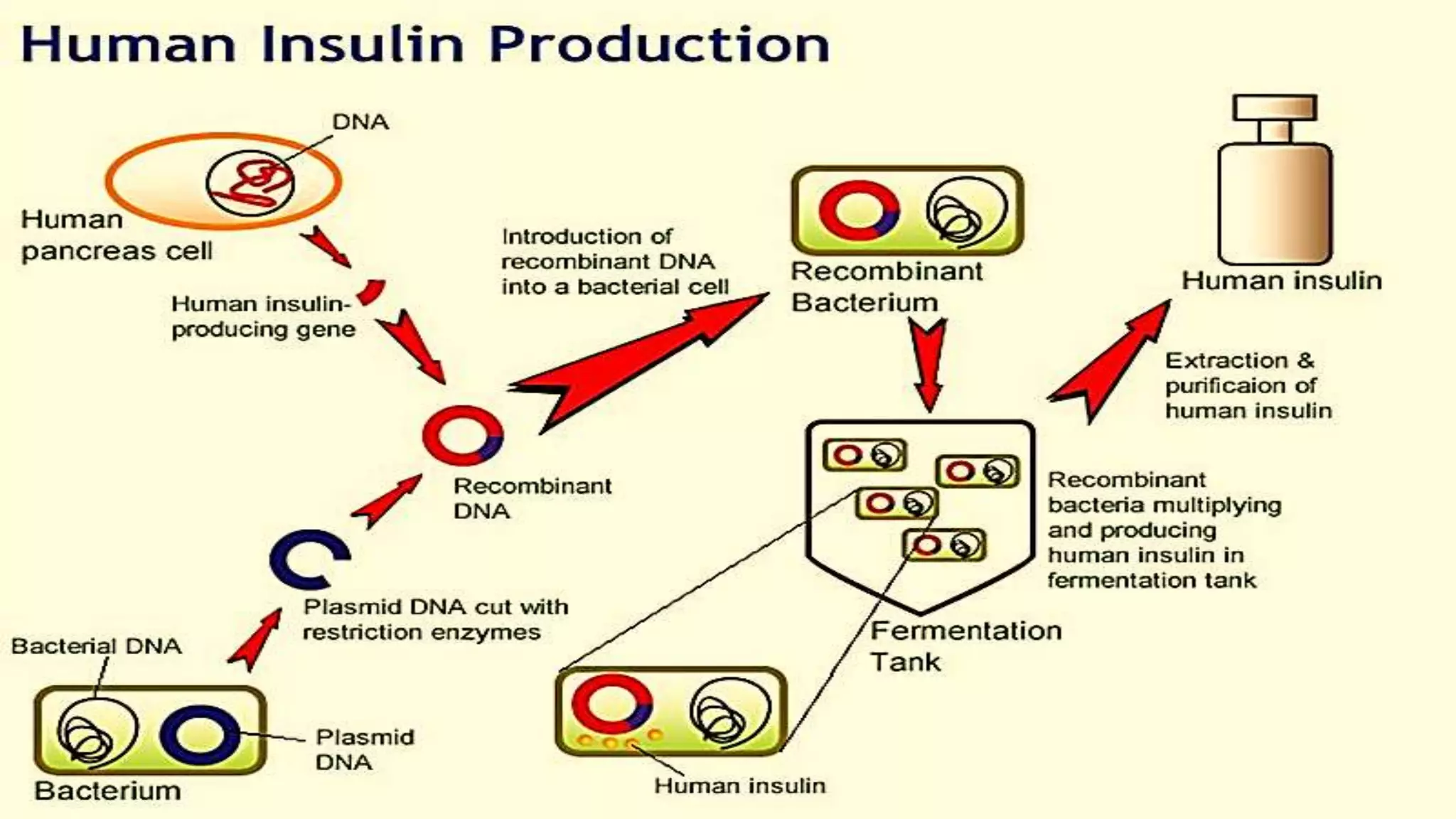

The document discusses insulin, including its structure, gene location, processing in the body, and treatment of diseases related to insulin deficiency. Insulin is produced in the pancreas and enables cells to take up glucose. The human insulin gene is located on chromosome 11. Insulin is composed of two peptide chains linked by disulfide bonds. Treatment for insulin deficiency involves injection of insulin extracted from animals or recombinant human insulin produced using biotechnology. Recombinant human insulin is made through bacterial or yeast expression systems using vectors like plasmids or yeast artificial chromosomes.