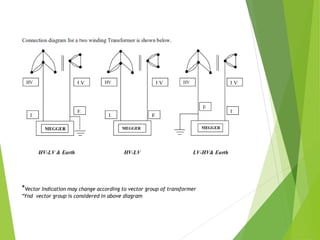

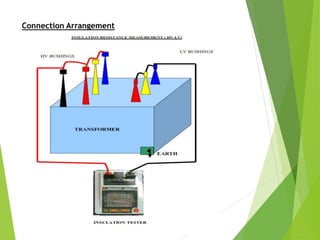

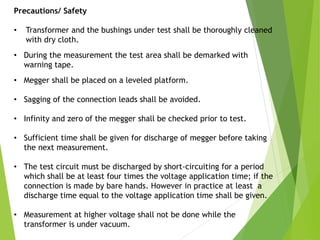

Insulation resistance testing measures the resistivity of transformer insulation to verify acceptability and detect damage. The test involves measuring insulation resistance values at specific time intervals and calculating the polarization index. Acceptable polarization index values indicate good insulation dryness and condition, while lower values suggest issues. Proper cleaning, connections, and safety precautions are important when performing the test.