This document discusses different types of tests performed on insulators. It describes three main categories of insulator tests: type tests, sample tests, and routine tests. Type tests are designed to determine if a particular insulator design is suitable for its intended purpose. Sample tests are conducted on a few insulator samples and include tests like puncture voltage, porosity, mechanical loading, and electro-mechanical stress. Routine tests are shorter tests done on all manufactured insulators to check for defects. Examples given are mechanical load and corrosion resistance tests.

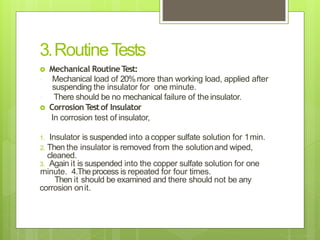

![1. Type Test.

These tests are done to determine whether the particular design is suitable

for the purpose.

(a) Withstand Test:

Specified voltage is applied.

Flashover or puncture should not occur. [otherwisepermanently

damaged].

The test is repeated five times for eachpolarity.

(b) Dry One-minuteTest

The insulator (dry) at prescribed voltage should be gradually brought up

and maintained for onemin.

There shall not be puncture or flash-over during the test.

(c) Dry flash-overtest:

The voltage shall then be increased gradually until flash-overoccurs.

This is repeated ten times. There shall be no damageto theinsulator.](https://image.slidesharecdn.com/testsoninsulators-180224154442/85/Tests-on-insulators-6-320.jpg)