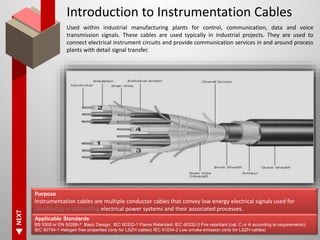

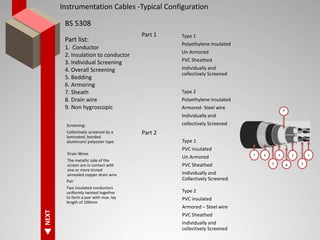

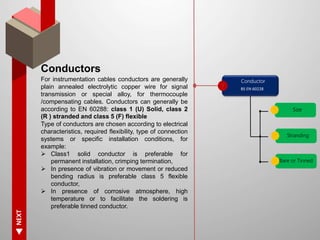

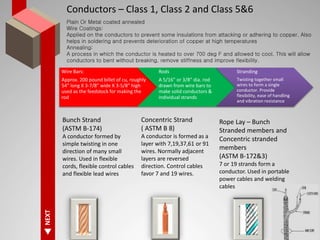

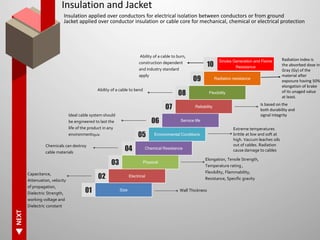

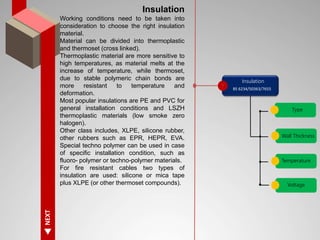

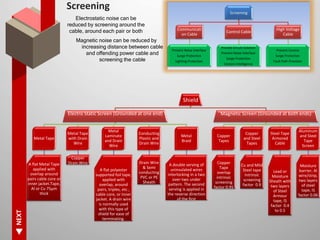

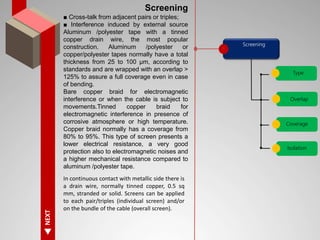

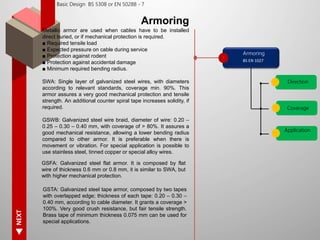

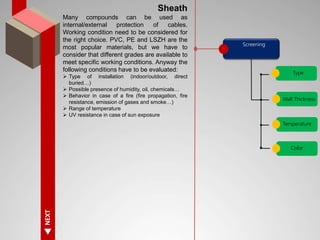

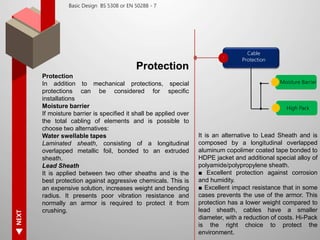

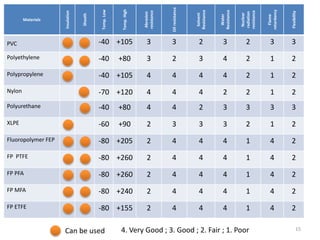

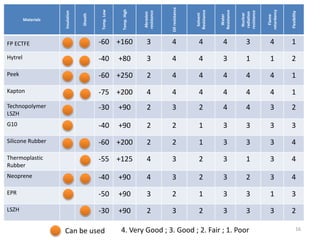

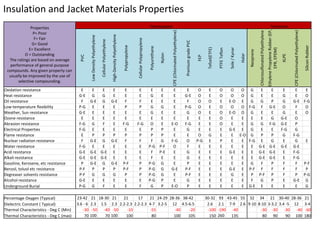

This document provides information on instrumentation cables, including their purpose, applicable standards, typical configurations, conductor types, insulation, screening, armoring, sheathing, and protection. Instrumentation cables are multiple conductor cables that convey low energy electrical signals for industrial processes. They are commonly used in industrial projects to connect electrical instrument circuits and provide communication services around process plants. The document discusses cable components, materials, and specifications according to various standards like BS 5308.