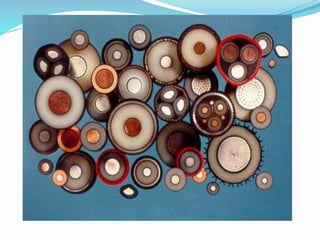

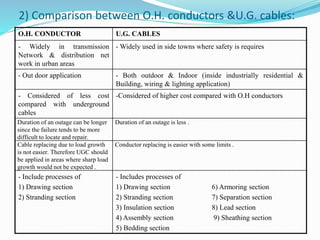

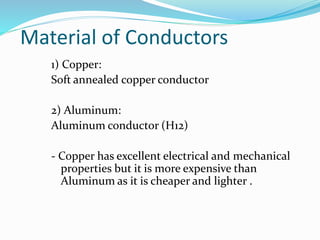

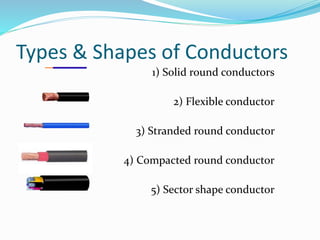

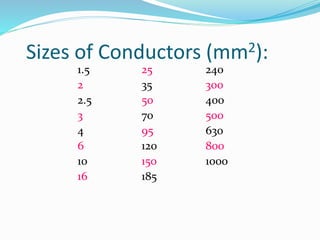

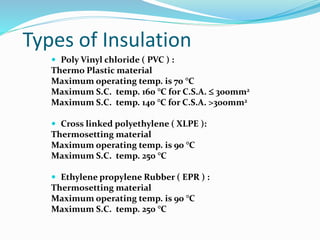

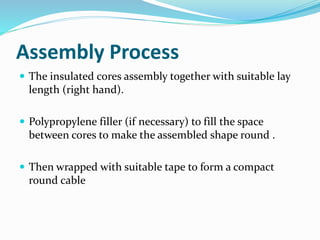

This document provides an overview of low voltage power cables. It discusses cable design principles including voltage ratings, conductor materials and sizes, insulation types, core identification, assembly processes, bedding, armoring, sheathing, and relevant standards. The key points are that low voltage cables operate between 300/500V and 600/1000V, use copper or aluminum conductors, and common insulation materials are PVC, XLPE, and EPR. Cores are typically identified by color and the document outlines the assembly, bedding, armoring, and sheathing processes. Finally, common international and national standards for low voltage cables are listed.

![Voltage Grades of L.V. Cables:

300/500 V [Both sheath & non-sheath cable (insulated

wires)]

450/750 V [non-sheathed cables (insulated wires)]

600/1000 V or 0.6/1 kV (Sheathed cables)](https://image.slidesharecdn.com/cablecourse-221119041634-8329c2a1/85/Cable-Course-pptx-20-320.jpg)

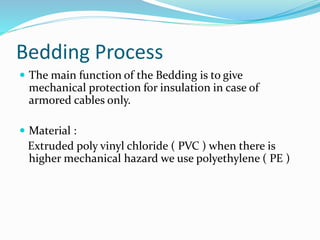

![In case of mechanical hazard we can use

polyethylene materials such as

High Density Polyethylene [HDPE]

Medium Density Polyethylene [MDPE]

Linear Low Density Polyethylene [LLDPE]](https://image.slidesharecdn.com/cablecourse-221119041634-8329c2a1/85/Cable-Course-pptx-31-320.jpg)