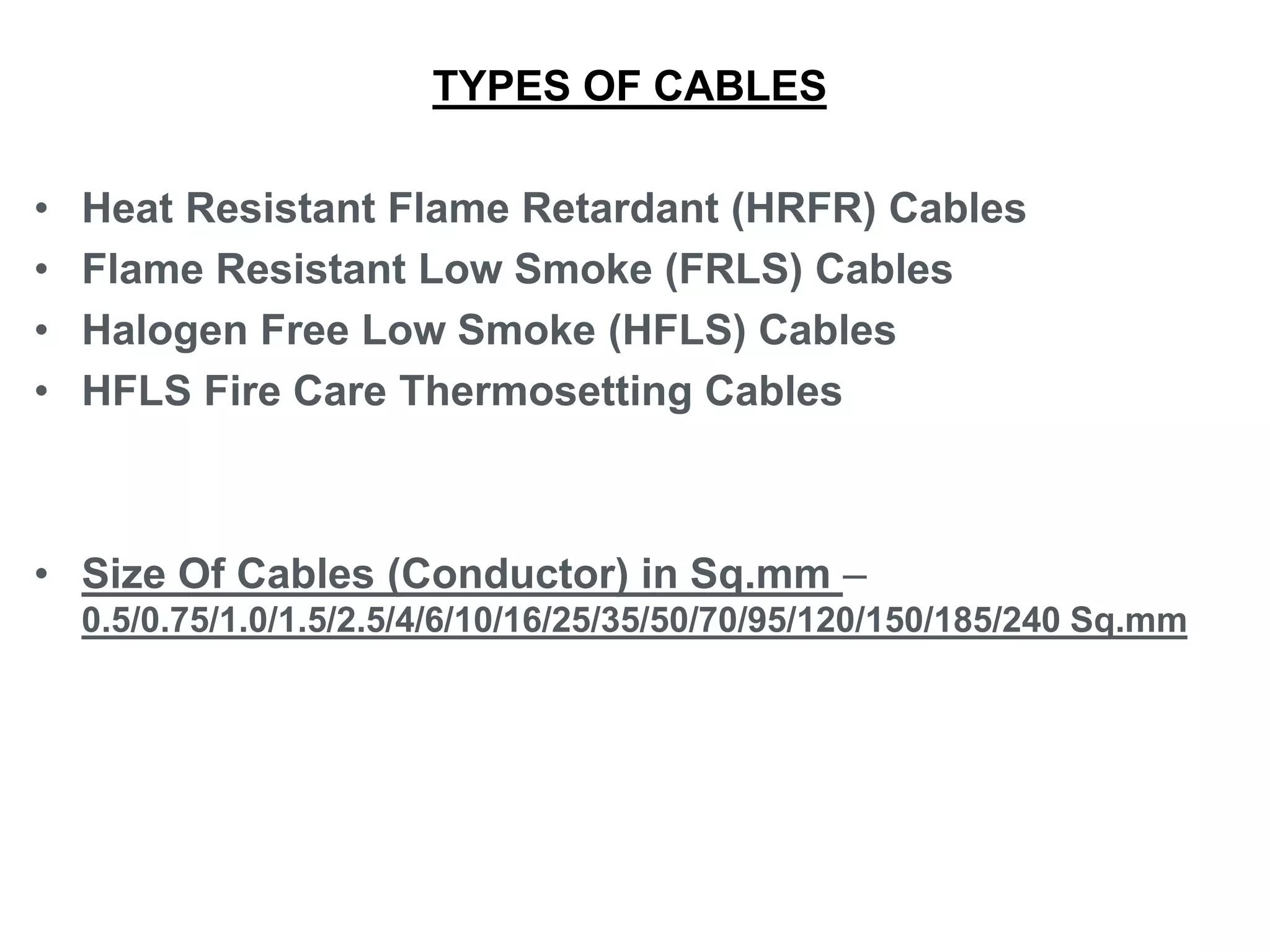

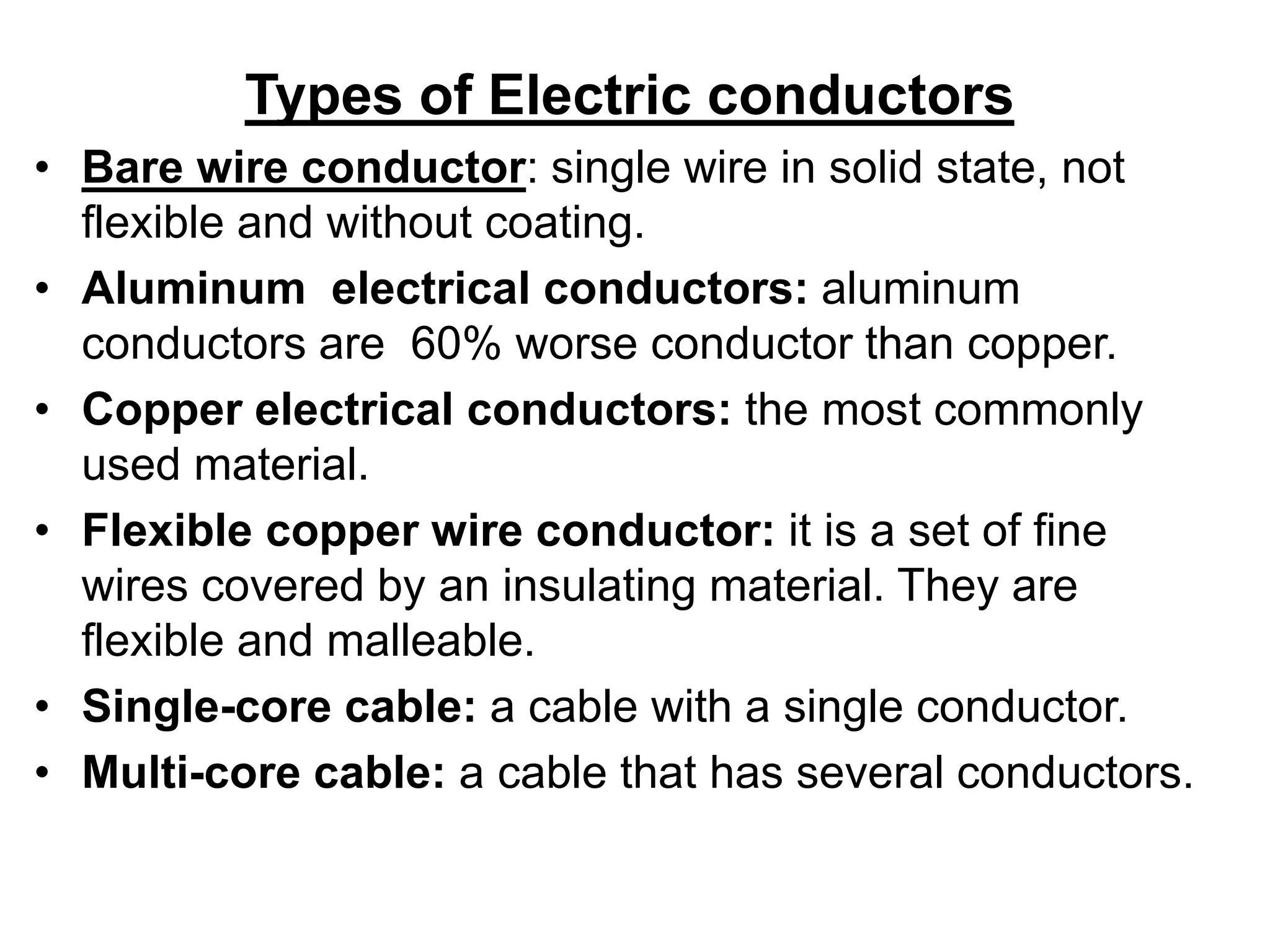

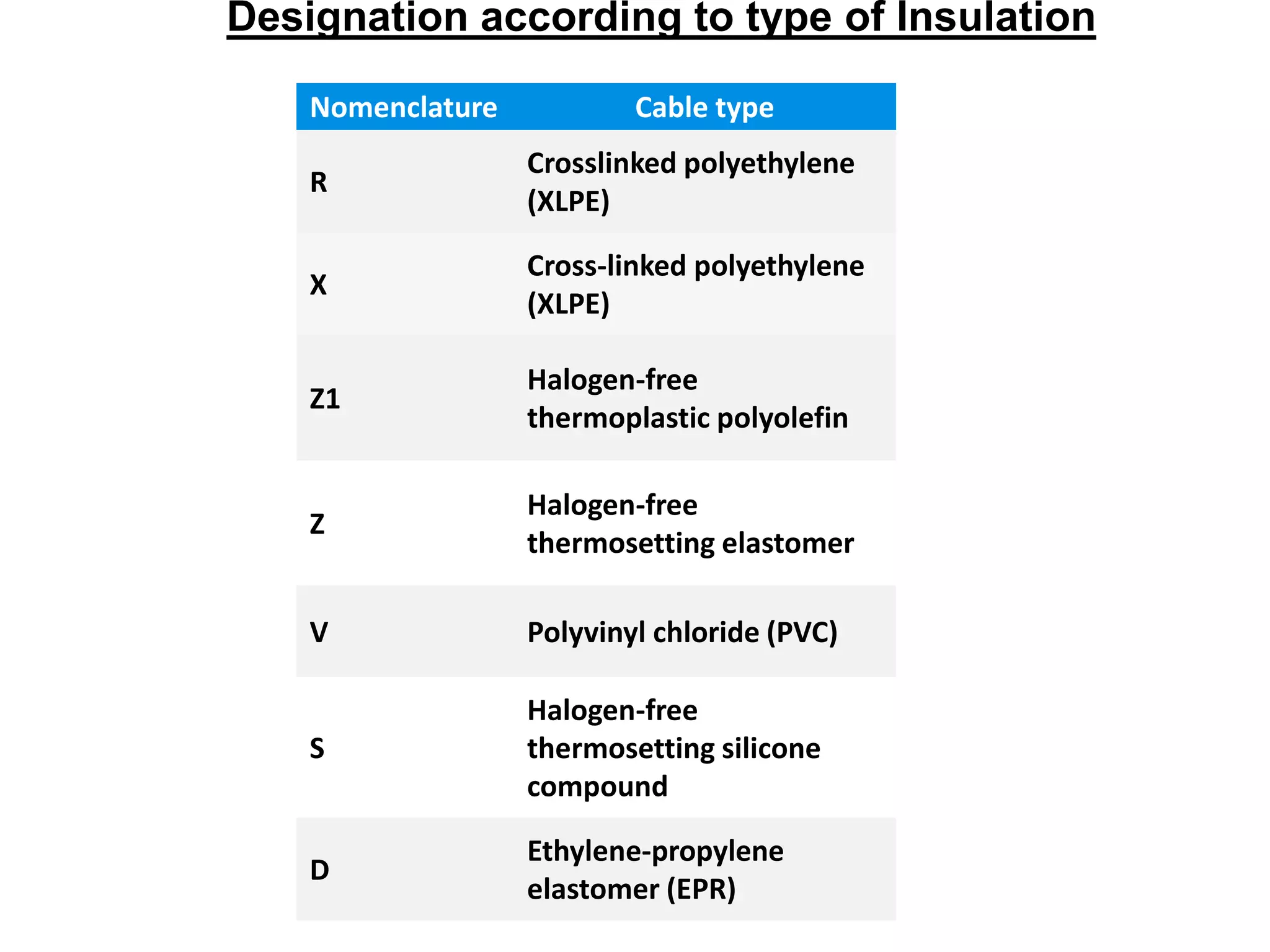

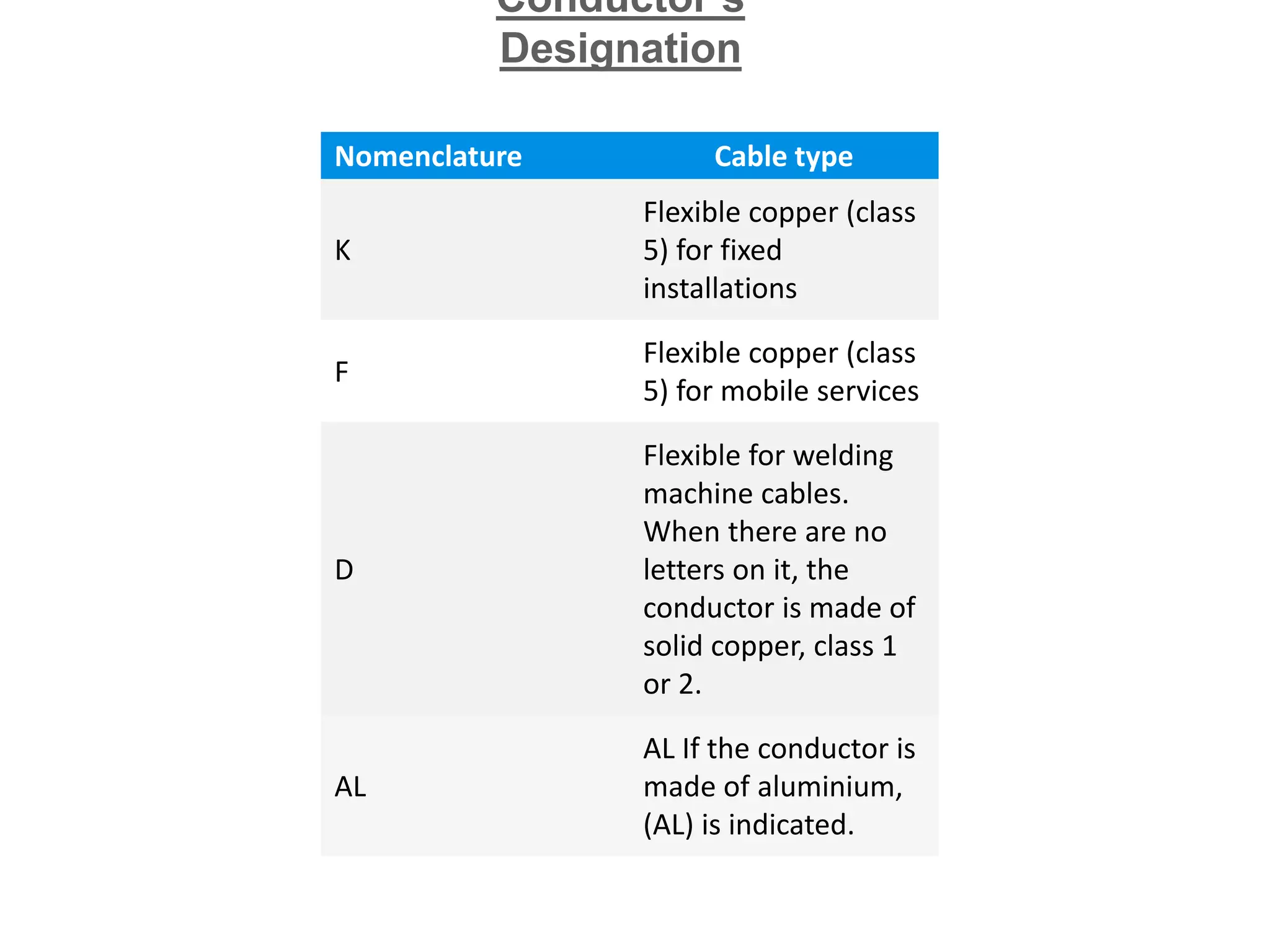

This document discusses types of electrical cables used in house wiring. It describes several types of cables including heat resistant flame retardant cables, flame resistant low smoke cables, and halogen free low smoke cables. It also discusses cable components like the conductor, insulation, auxiliary elements, and outer sheath. Various types of insulations are described including thermoplastic and thermosetting insulations. Cable nomenclature and color coding standards are also summarized along with common units of measurement and tests performed on cables.