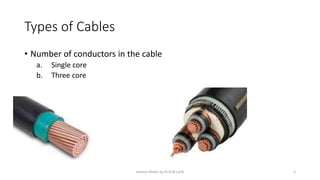

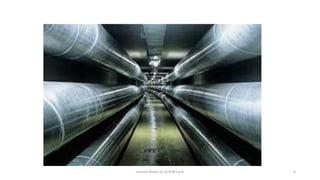

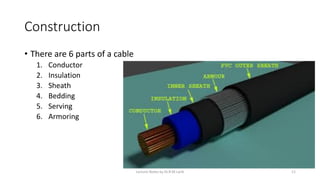

There are two main ways to transmit electrical power: overhead cables or underground cables. Underground cables have several advantages over overhead cables such as being safer, requiring lower maintenance, and having higher reliability. Underground cables come in various types depending on factors like the number of conductors, voltage rating, and insulating material used. Proper installation methods are also important, with options including direct burial, using troughs or tunnels. Cables have several components including conductors, insulation, sheathing, bedding, serving, and armoring. The choice of materials for each component depends on considerations like conductivity, insulation strength, and resistance to heat and chemicals.

![• Ductility-the material's ability to be stretched into a wire.

• Copper has a higher ductility than alternate metal conductors with the

exception of gold and silver.[18] Because of copper’s high ductility, it is easy

to draw down to diameters with very close tolerances.

• Creep resistance- the gradual deformation of a material from constant

expansions and contractions under “load, no-load” conditions. This process

has adverse effects on electrical systems: terminations can become loose,

causing connections to heat up or create dangerous arcing.

• Copper has excellent creep characteristics that minimizes loosening at

connections. For other metal conductors that creep, extra maintenance is

required to check terminals periodically and ensure that screws remain

tightened to prevent arcing and overheating

Lecture Notes by Dr.R.M.Larik 15](https://image.slidesharecdn.com/powercables-200710095632/85/Power-cables-15-320.jpg)