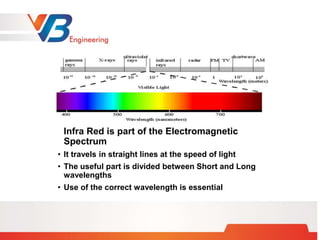

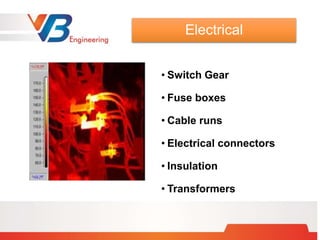

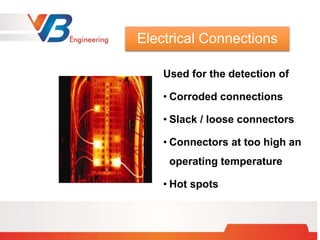

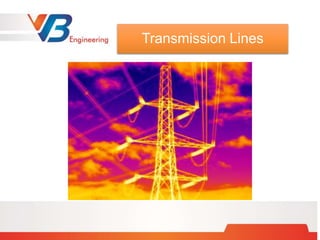

VB Engineering is an Indian company specializing in GIS and engineering integration, pioneering mobile app development, and GPS-based products. They successfully completed World Bank-funded projects in Africa and are the first to automate system study processes using advanced technology. The company emphasizes its expertise in thermal imaging and predictive maintenance through infrared thermography, aiming to improve product quality and reduce downtime across various industries.