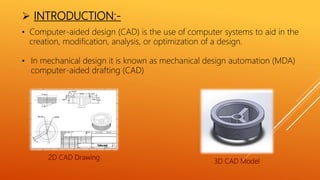

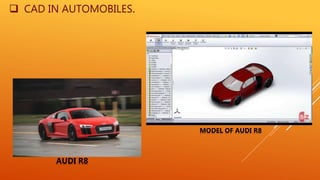

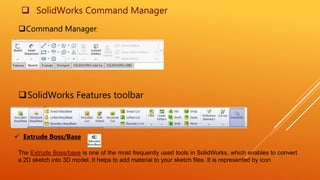

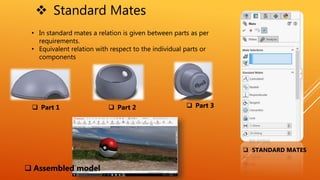

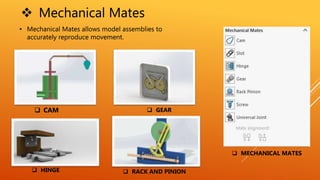

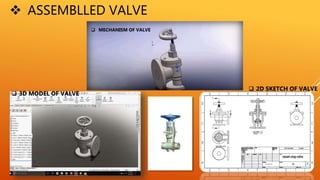

This document provides an overview of computer-aided design (CAD) software Solidworks. It discusses how CAD has evolved from paper drafting to 3D modeling to aid in design and manufacturing. Dassault Systems is introduced as the creator of Solidworks. Modeling methods in Solidworks like features/parts, command manager, and various modeling tools are explained. Other topics covered include surface modeling, sheet metal work, assembly mates, drawings, and examples like a gear train and safety valve projects. The document aims to introduce the capabilities and functions of the Solidworks CAD software.