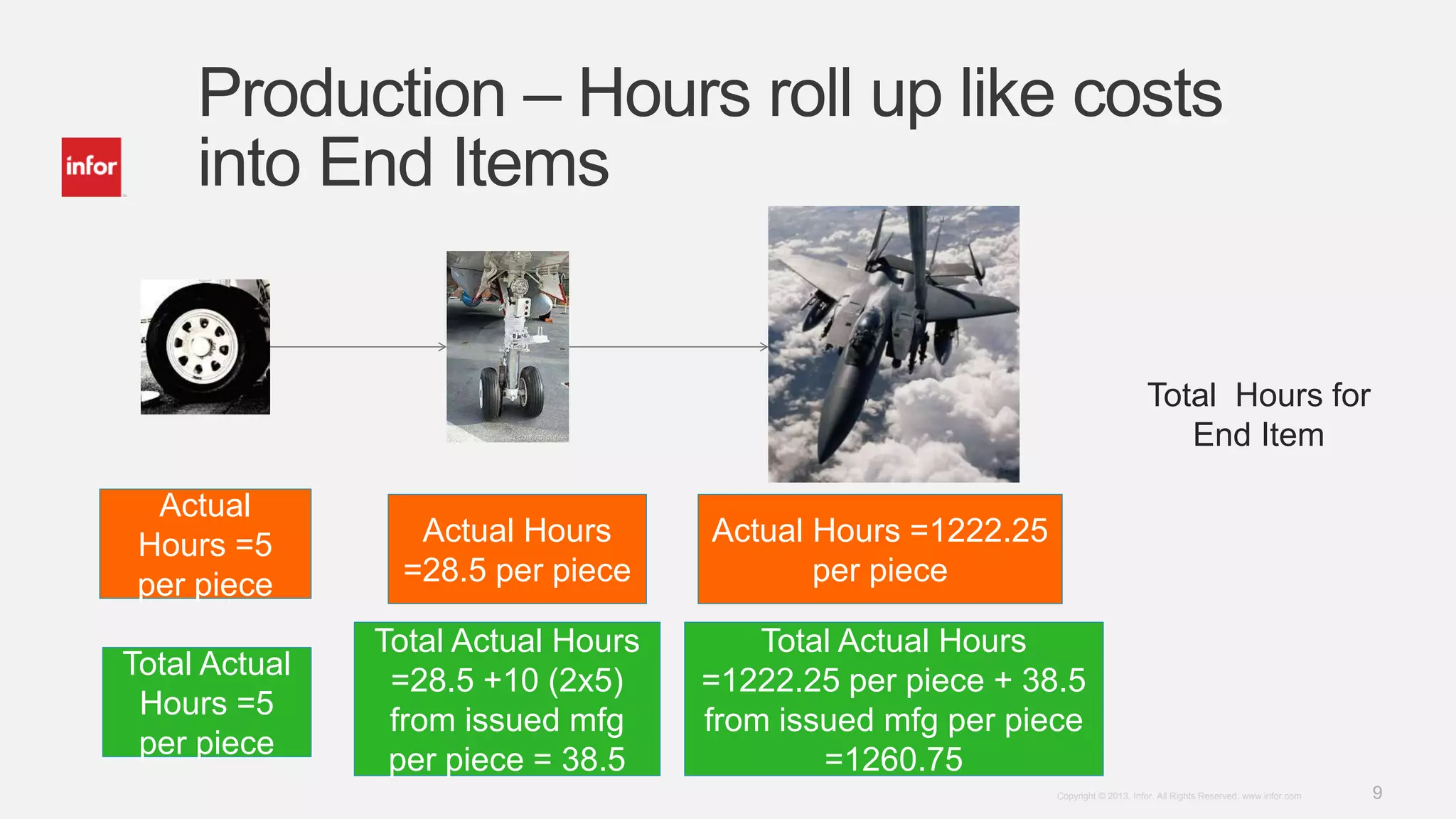

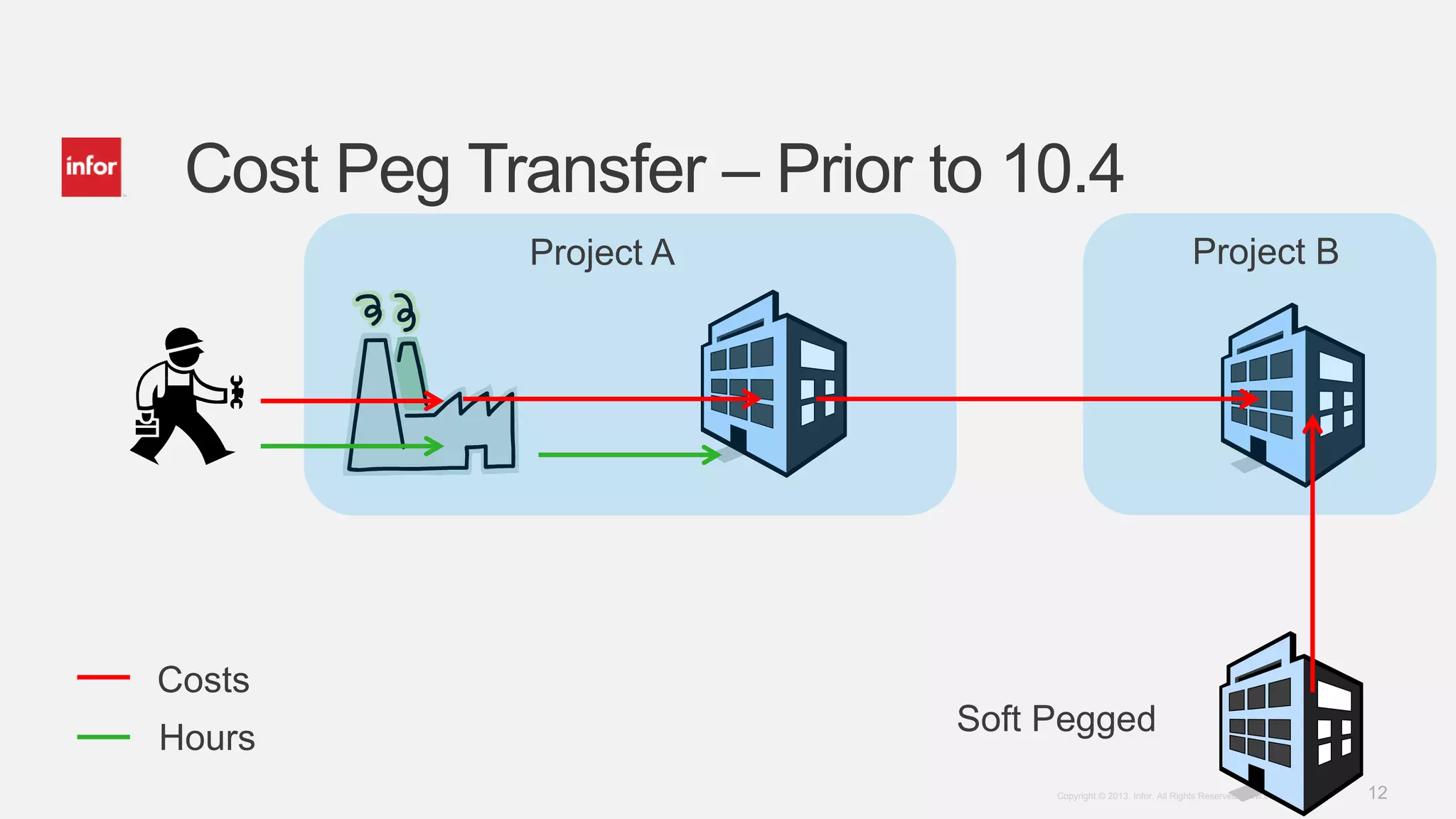

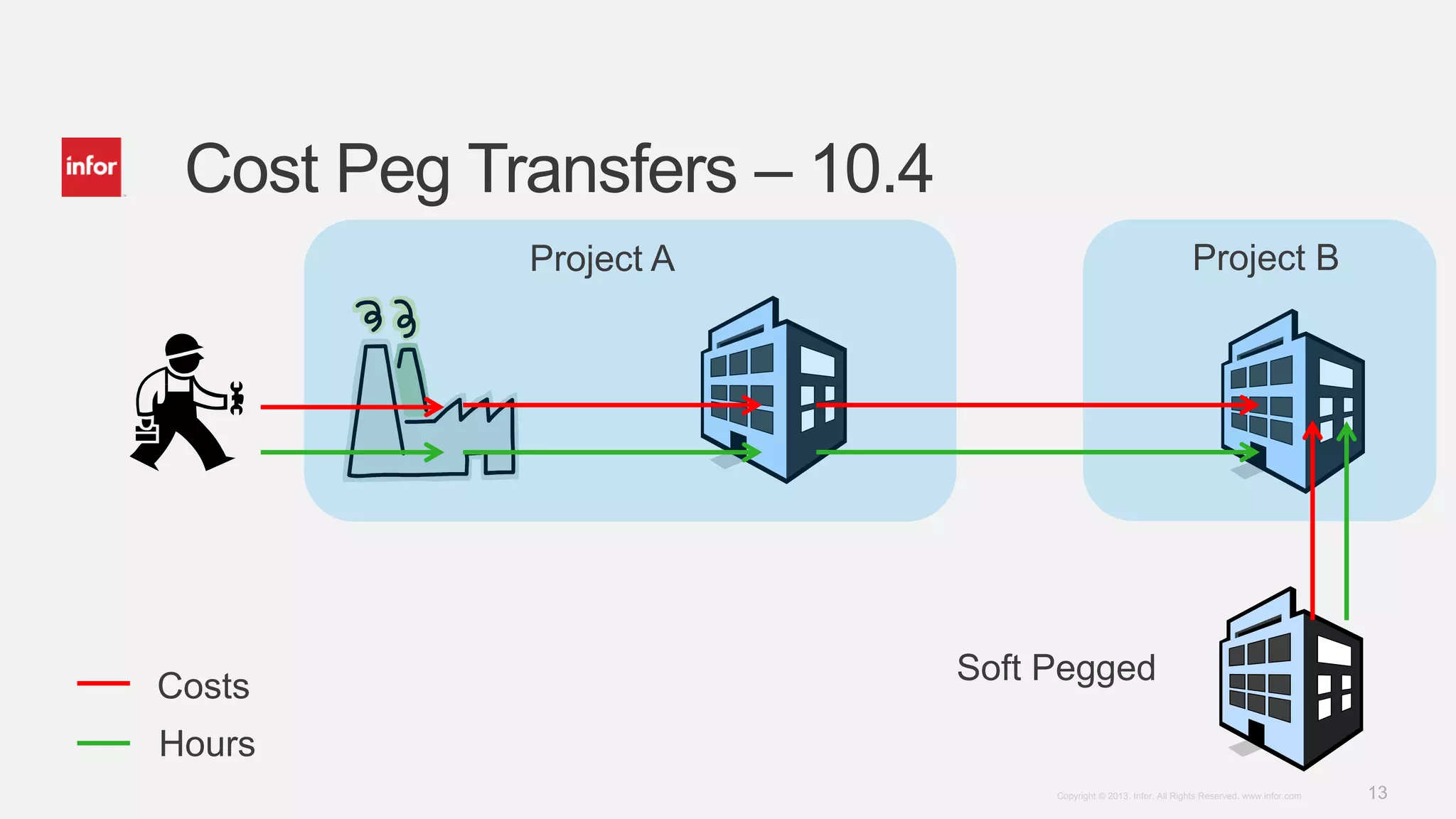

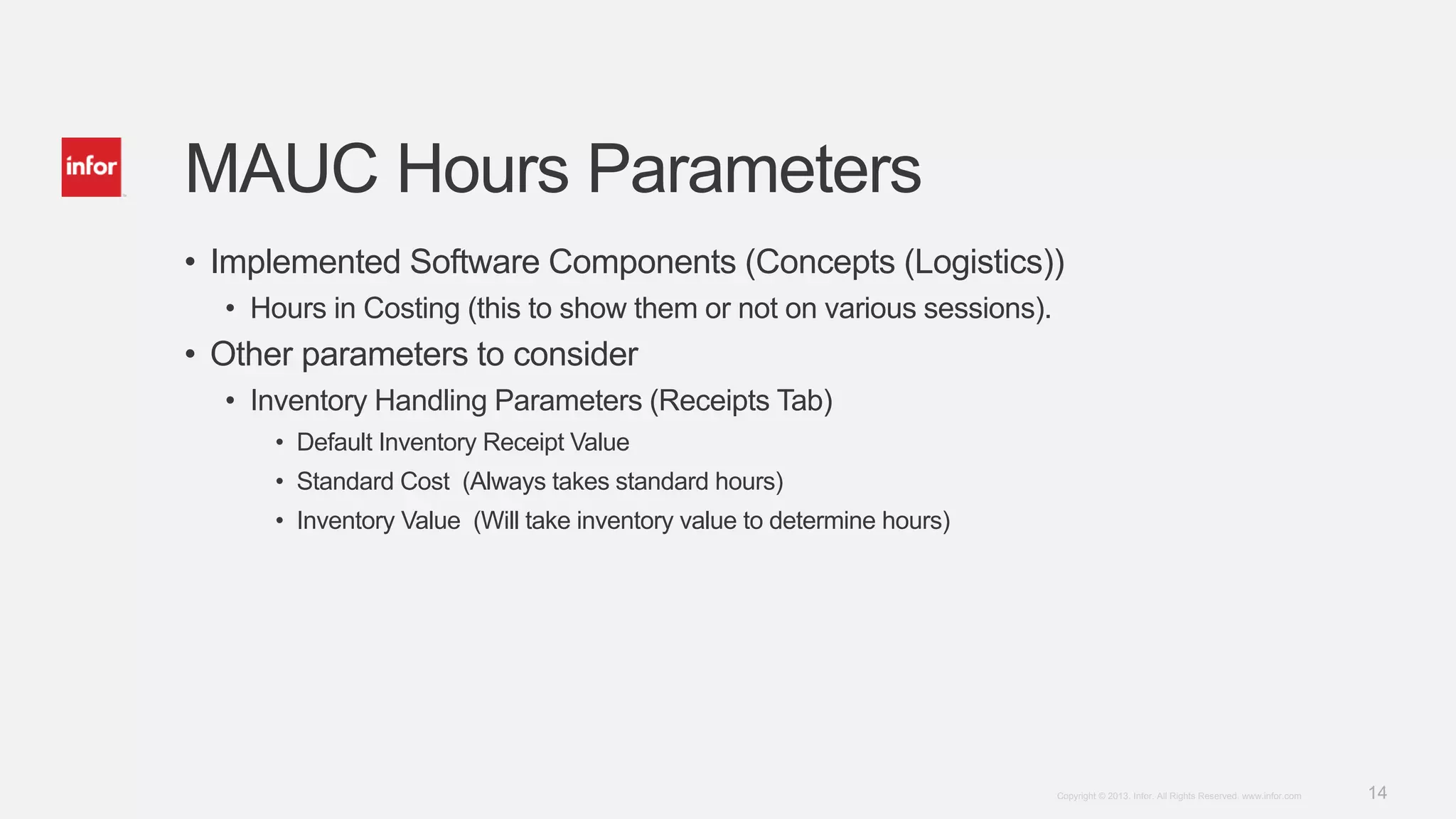

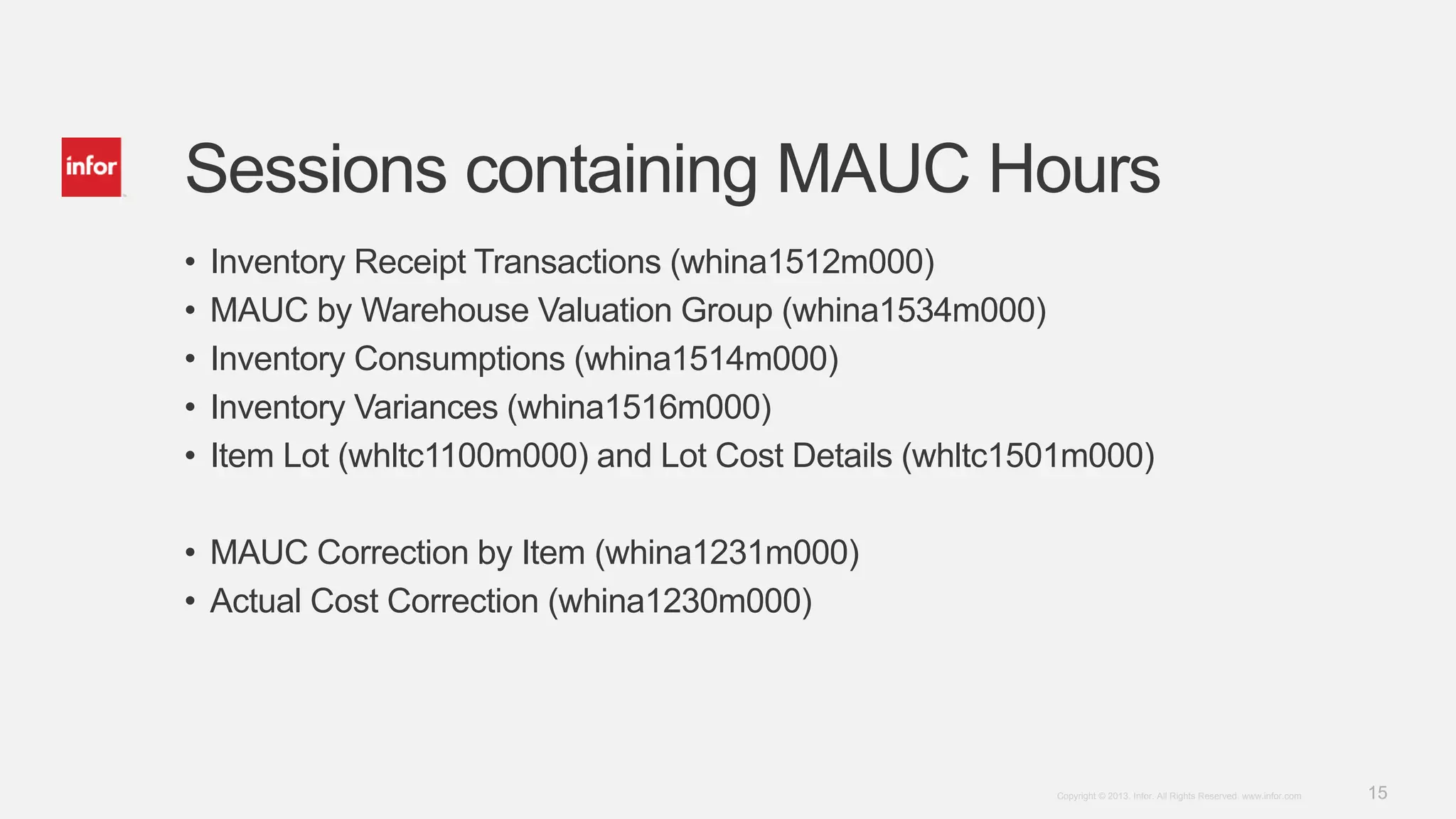

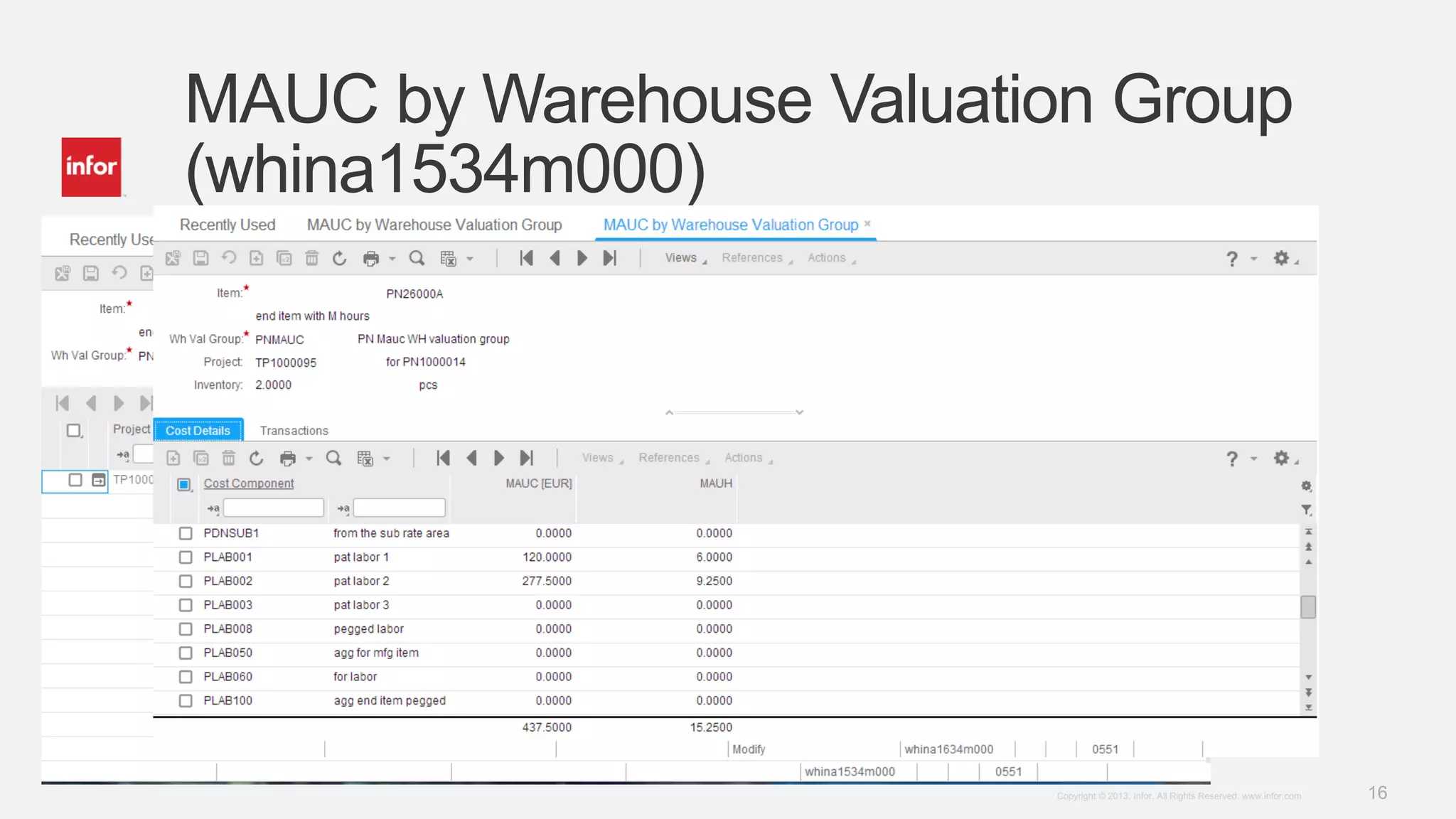

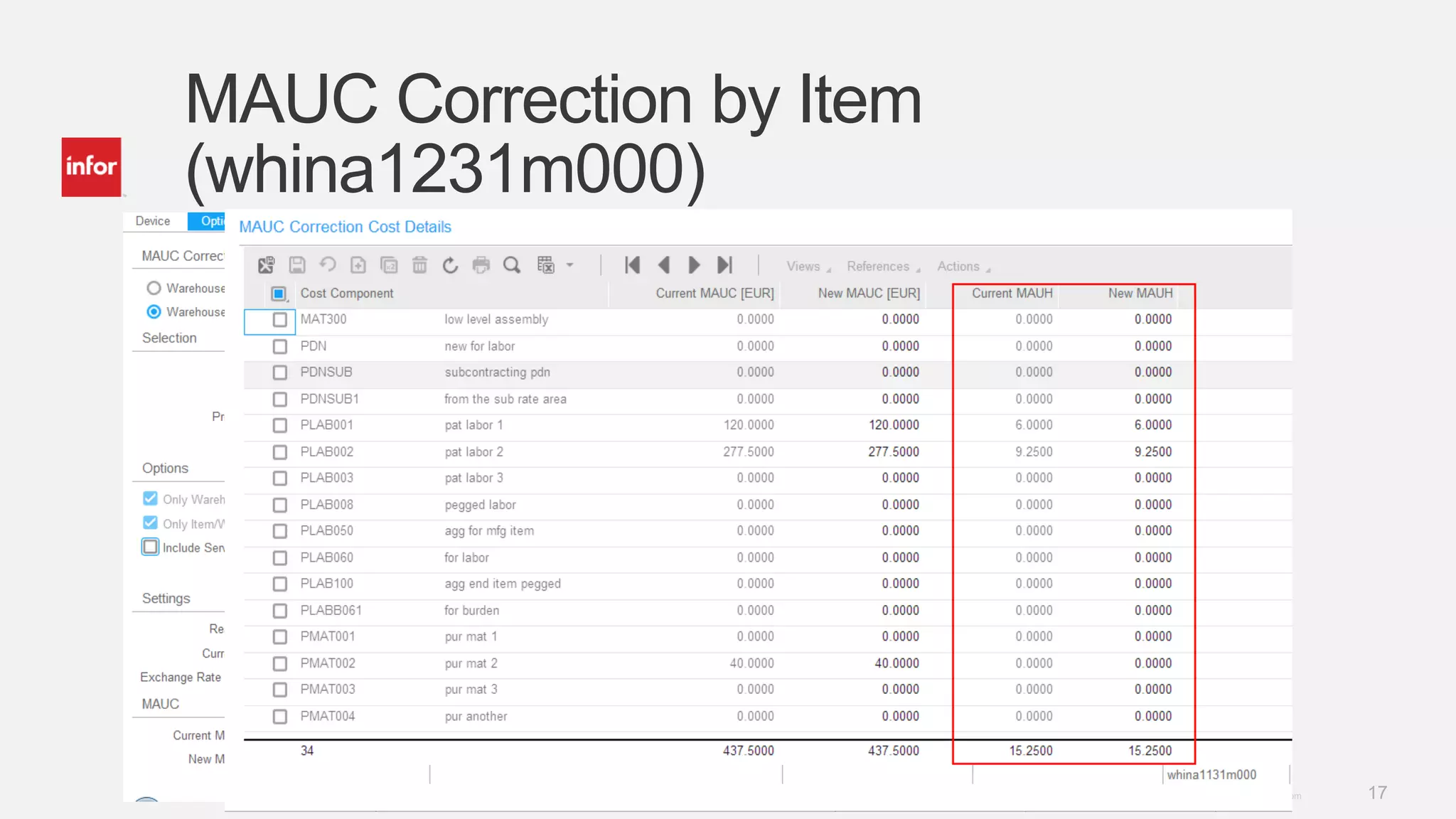

The document outlines the need for aerospace and defense (A&D) companies to incorporate moving average unit cost (MAUC) hours into their inventory valuation to ensure accurate overhead application and invoicing across projects. It details the business requirements and problems encountered due to the lack of production hours associated with item values, leading to incorrect costing and project profitability. The proposed solution includes retaining production hours and implementing a new software field for transferring hours and costs between projects.