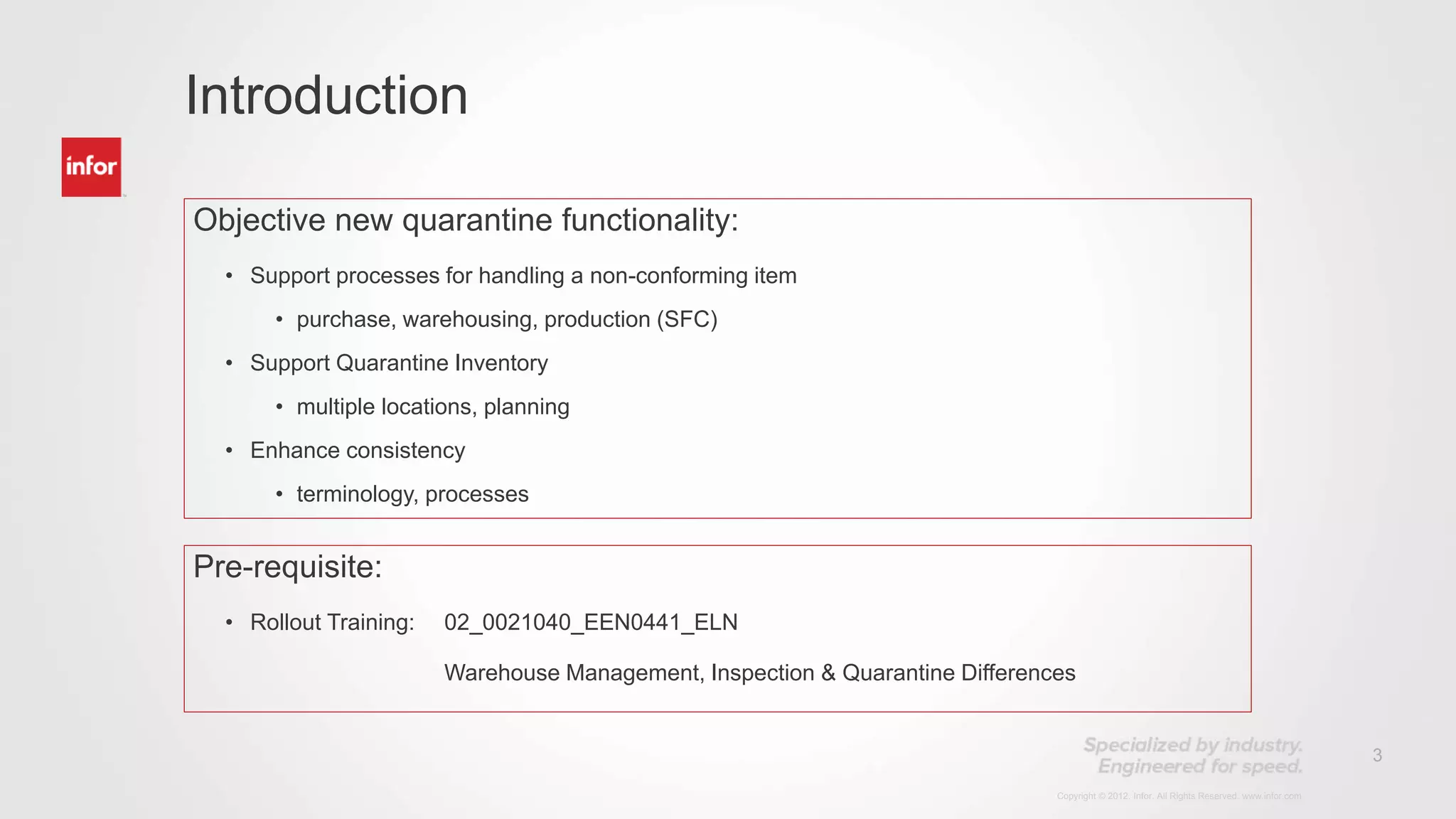

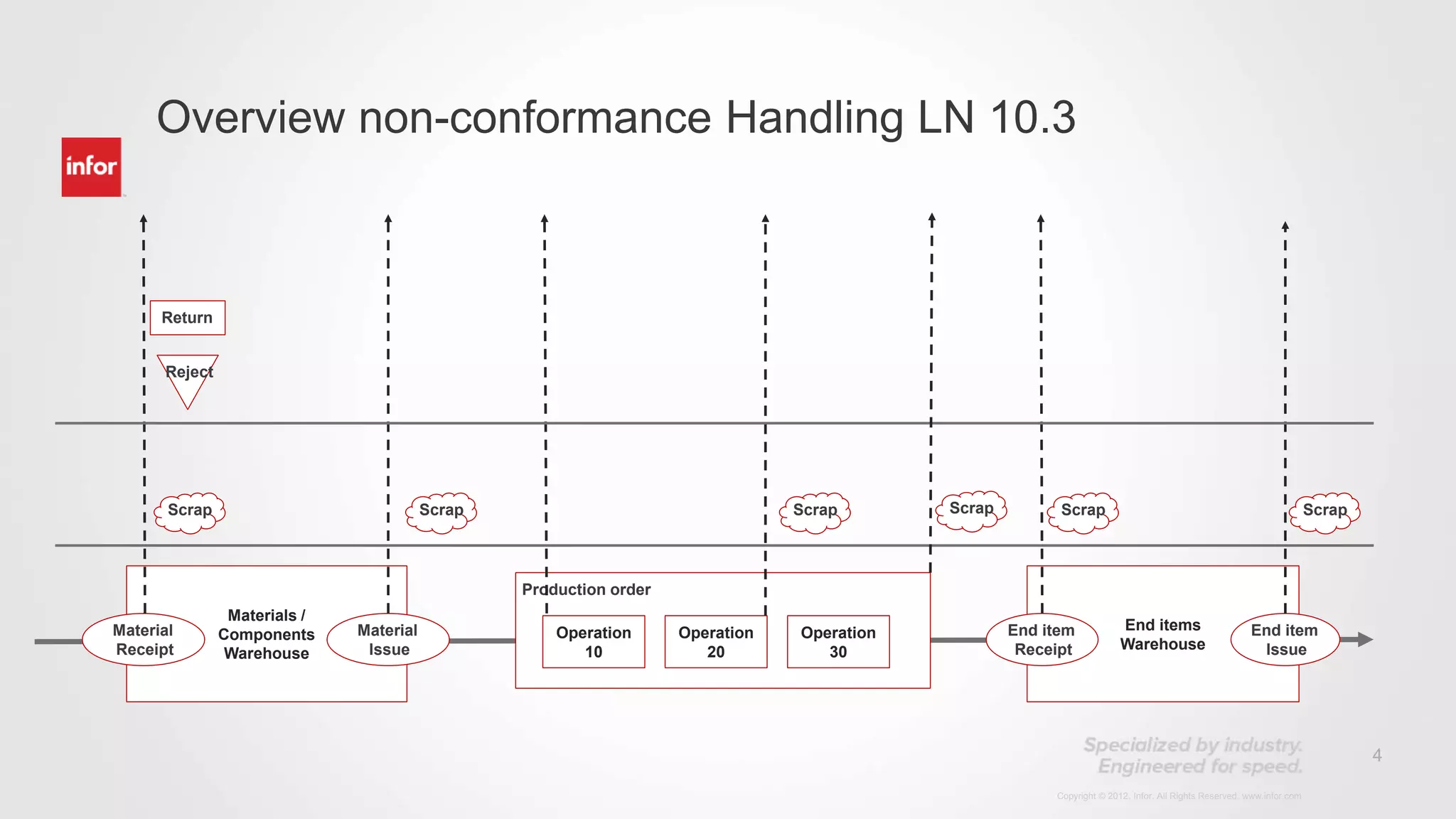

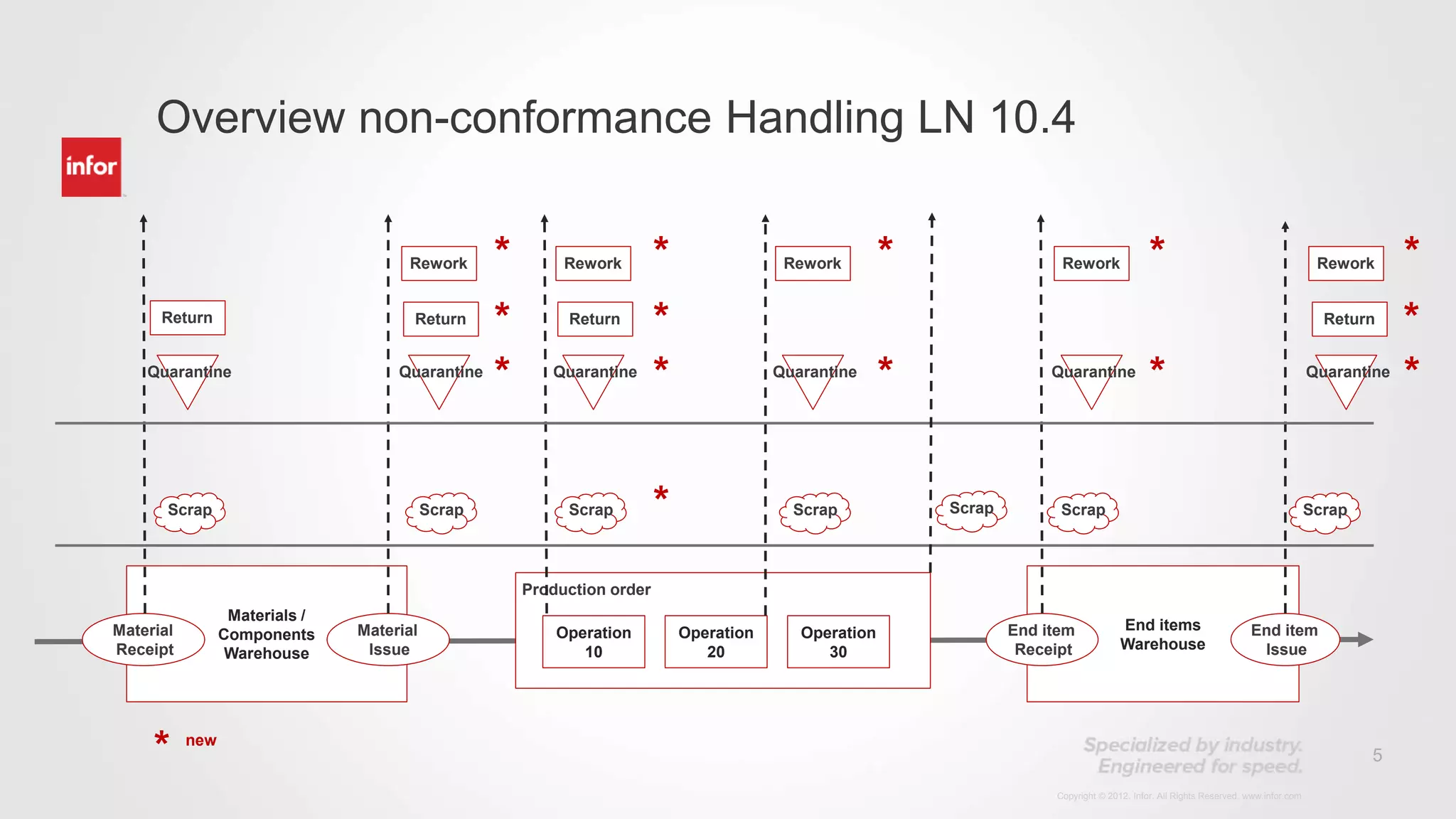

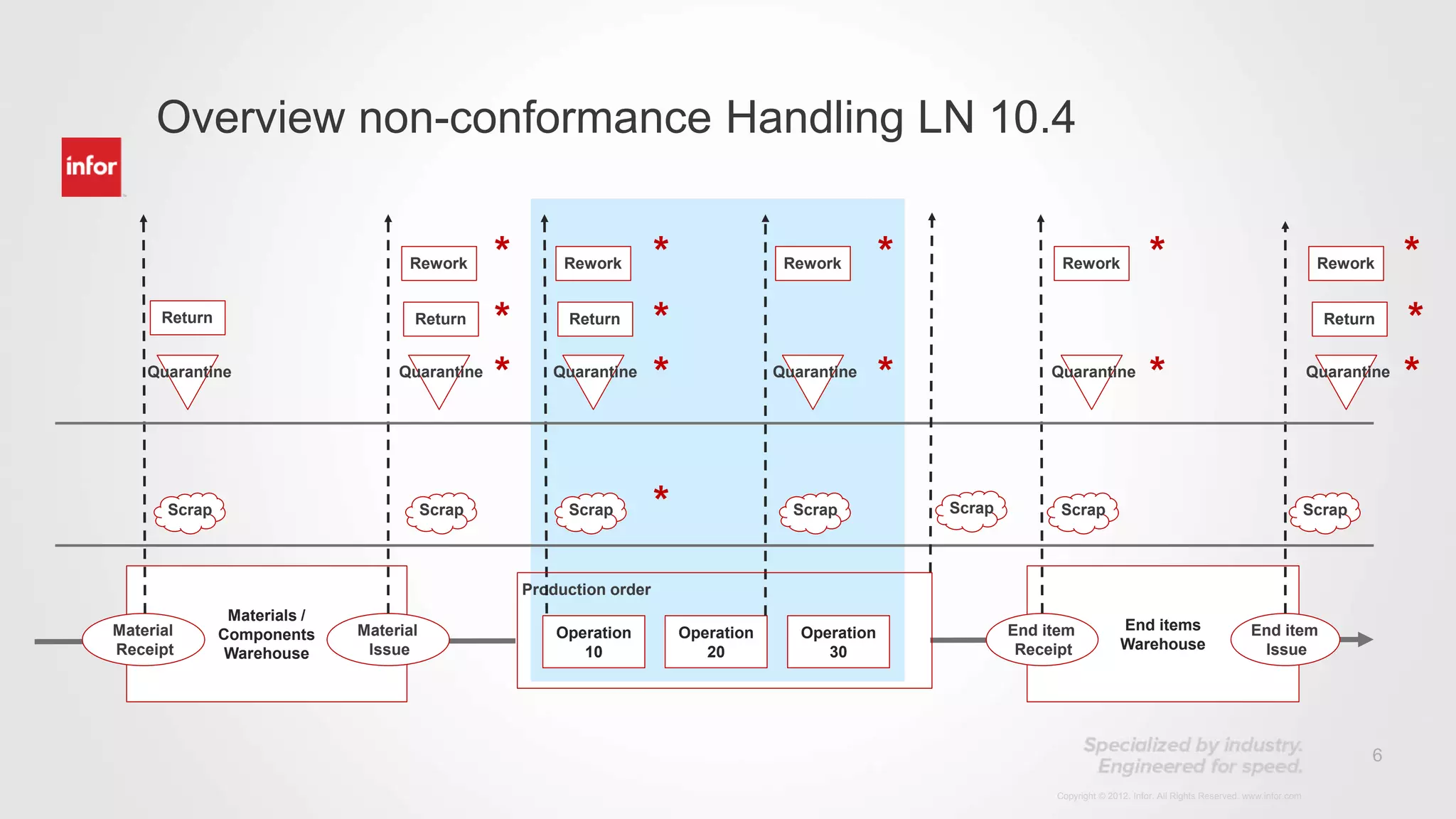

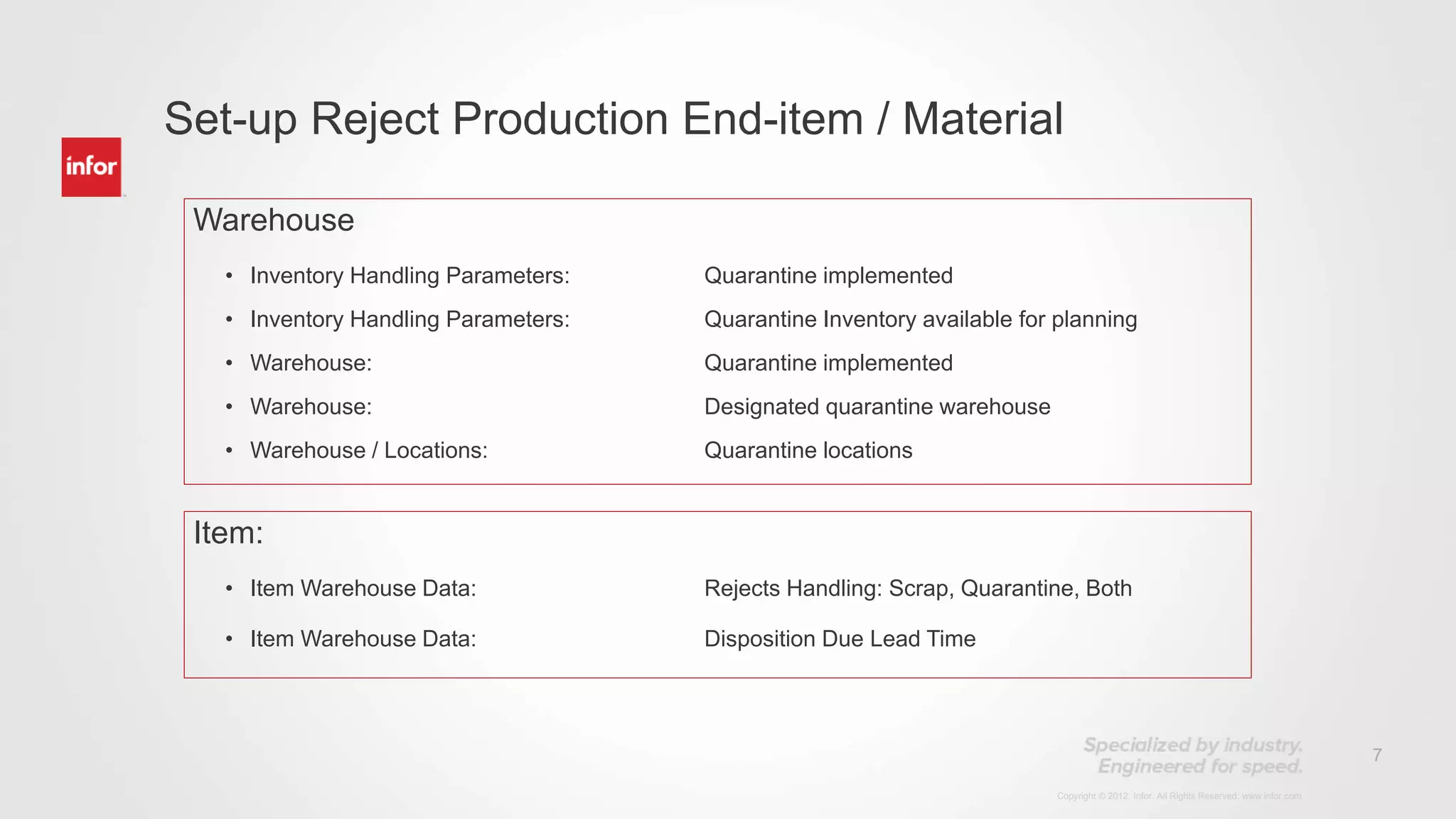

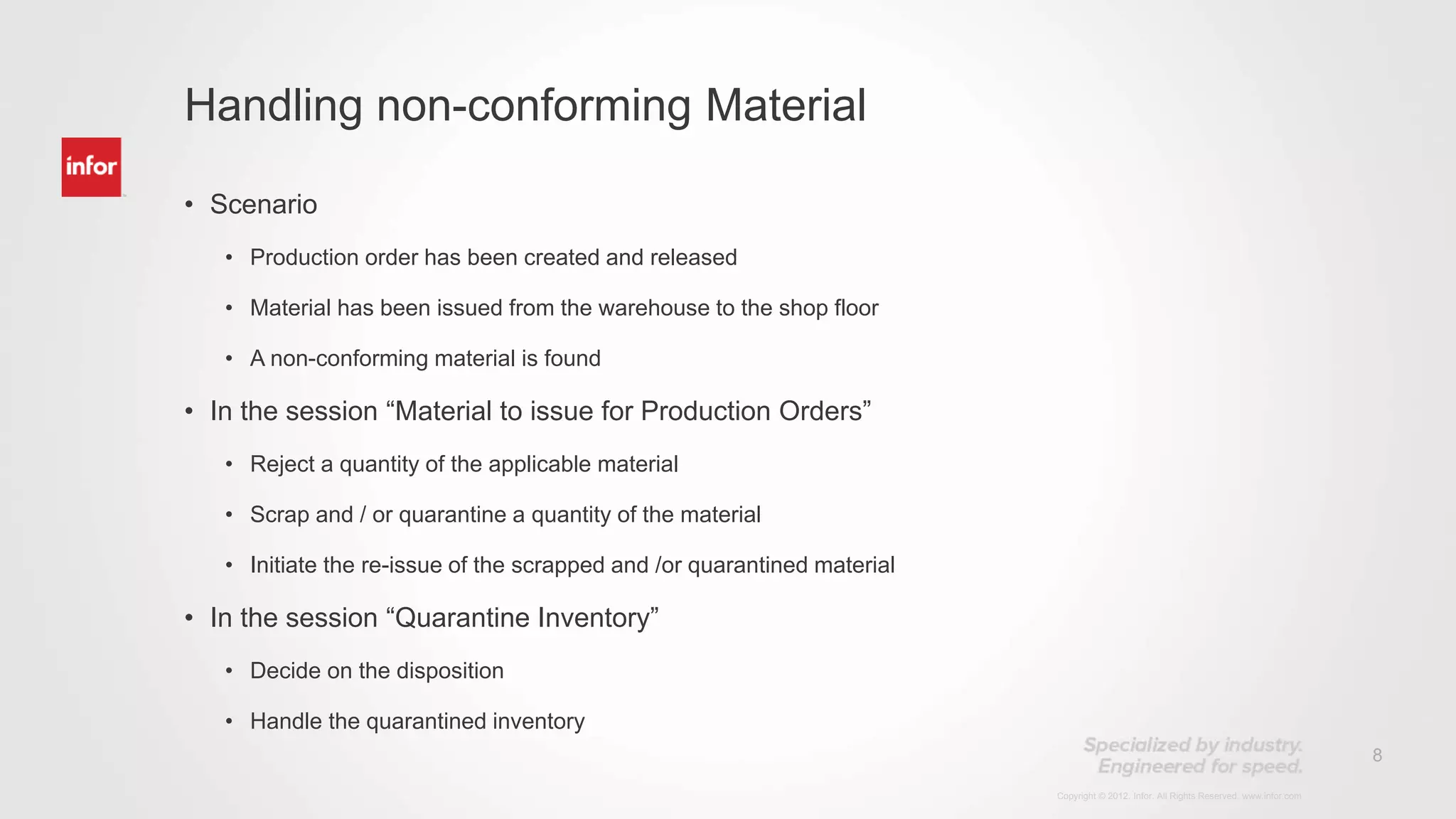

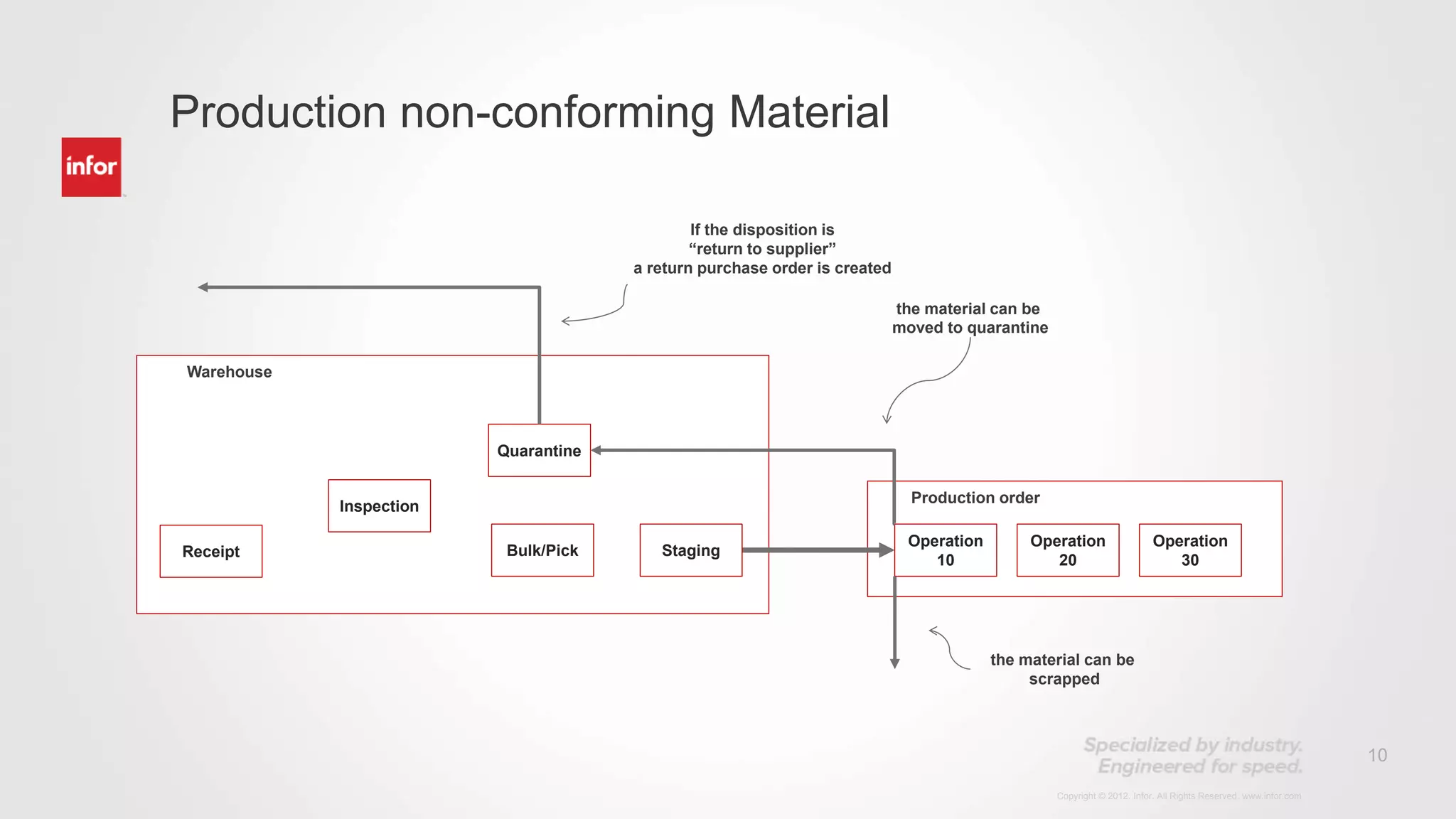

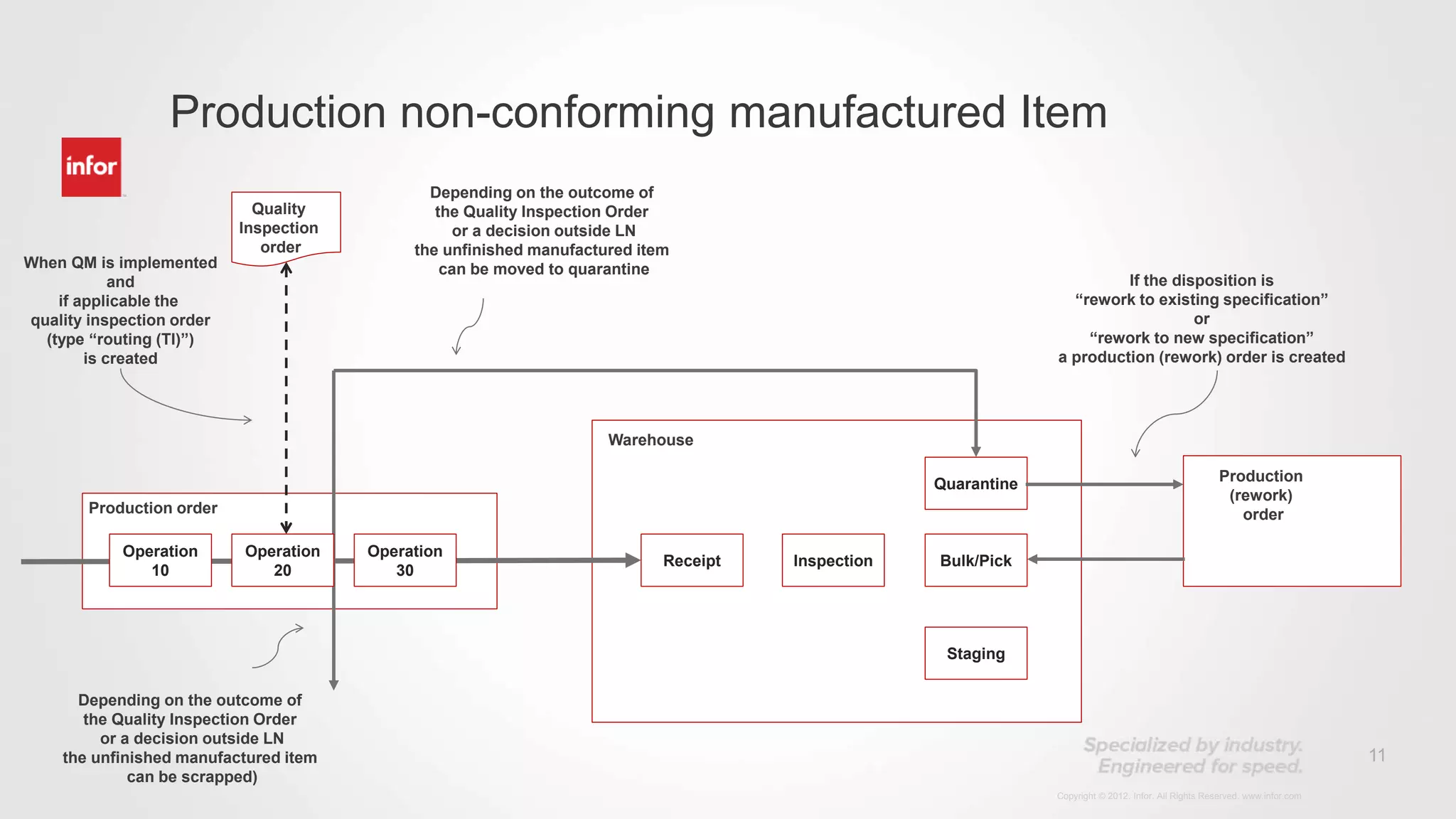

The document provides an overview of the differences in non-conformance handling between Infor LN versions 10.3 and 10.4. Key changes in 10.4 include the addition of a quarantine functionality to support processes for handling non-conforming items during purchase, warehousing and production. The quarantine functionality allows for multiple quarantine locations and supports quarantine inventory planning. The document also reviews how to set up and use the new quarantine functionality for rejecting non-conforming production materials and end items.