The document discusses induction bending as an alternative to conventional welding for fabricating pipe spools. Some key points:

- Induction bending reduces fabrication costs, time, and inspection costs compared to conventional welding by eliminating many welds.

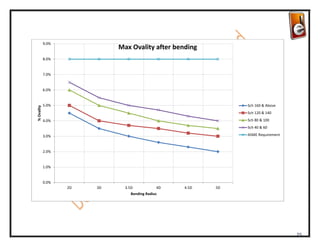

- It provides more flexibility in bending angles and radii compared to standard elbow fittings.

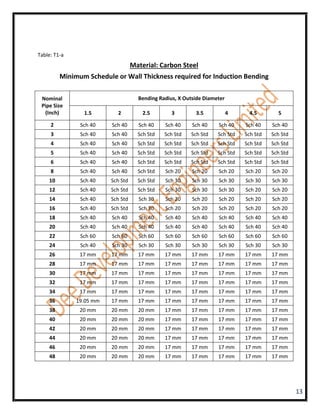

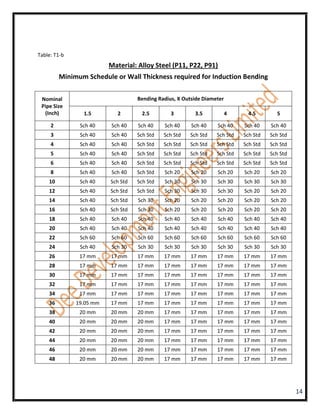

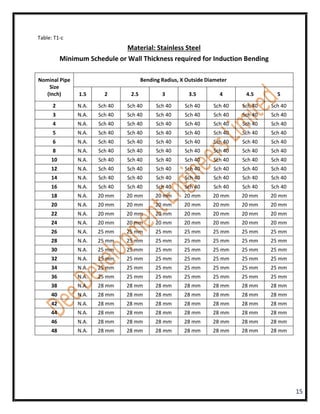

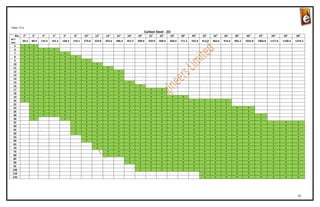

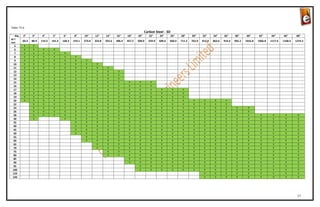

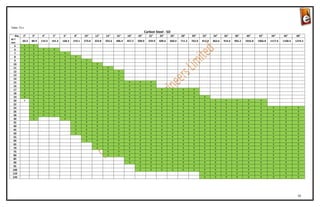

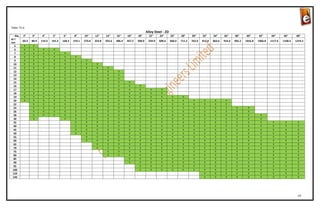

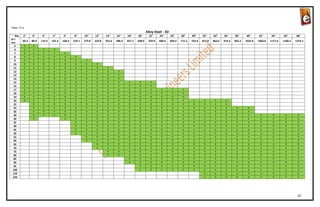

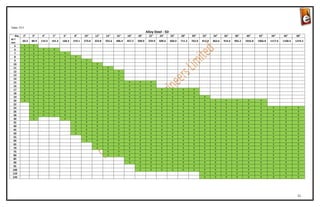

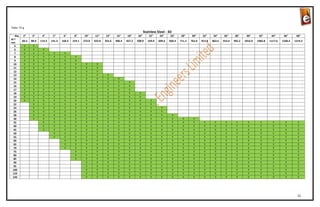

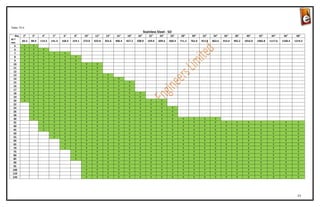

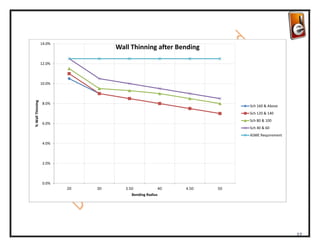

- Minimum bend radii depend on pipe diameter and wall thickness, ranging from 2D to 5D according to material type.

- Wall thinning must be considered and compensated for in pipe wall thickness calculations.

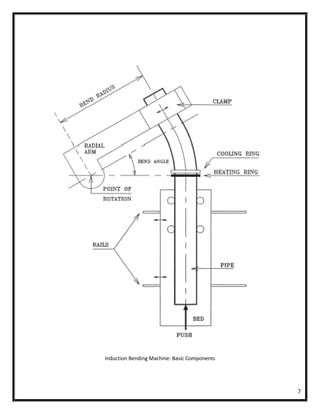

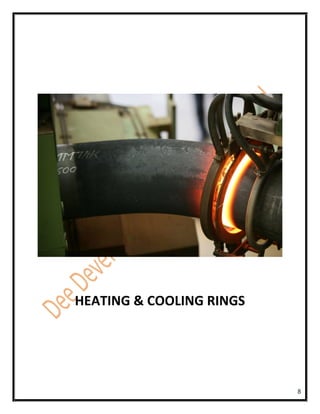

- The induction bending process involves heating a pipe section and bending it between clamped positions to form the desired radius.