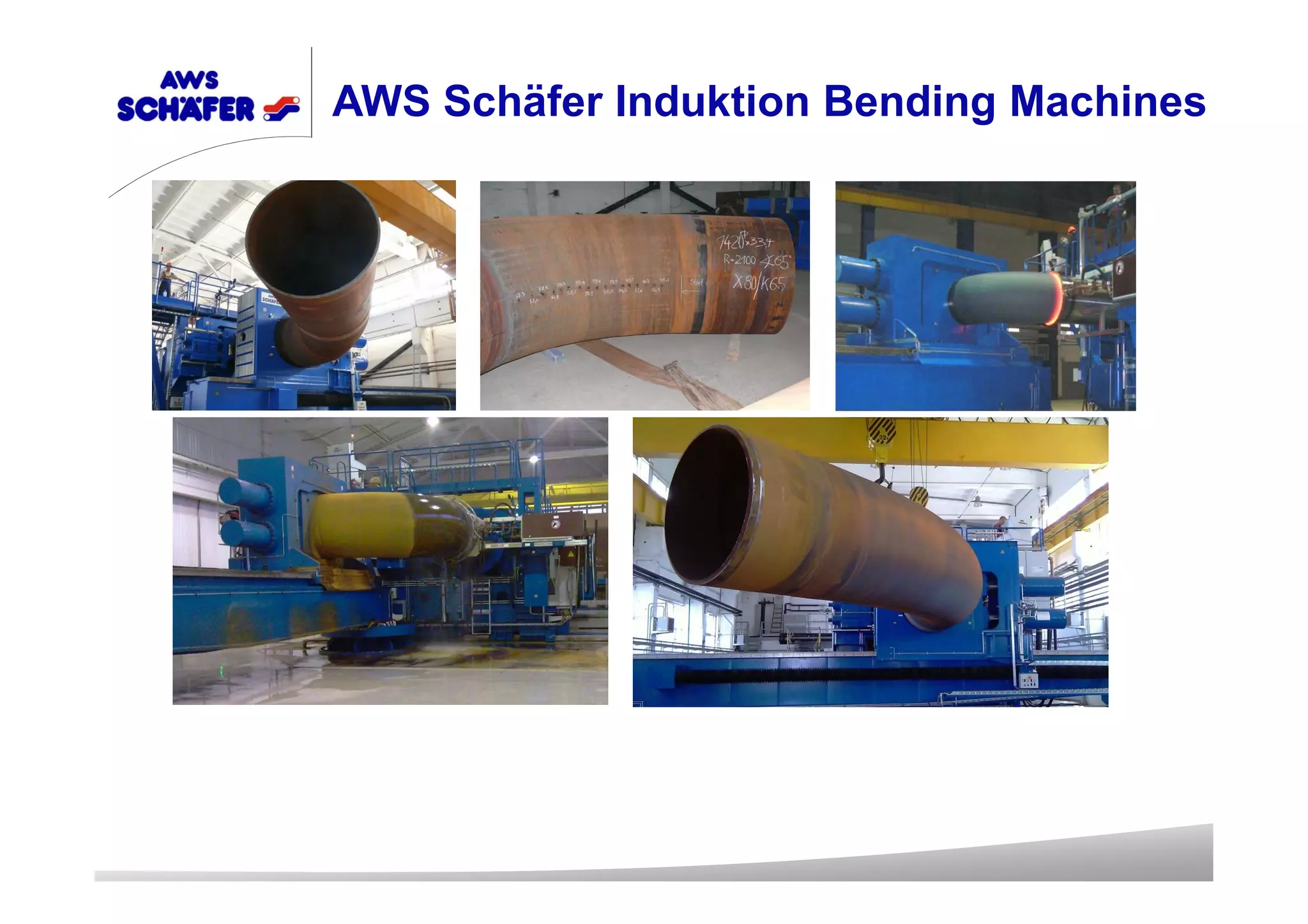

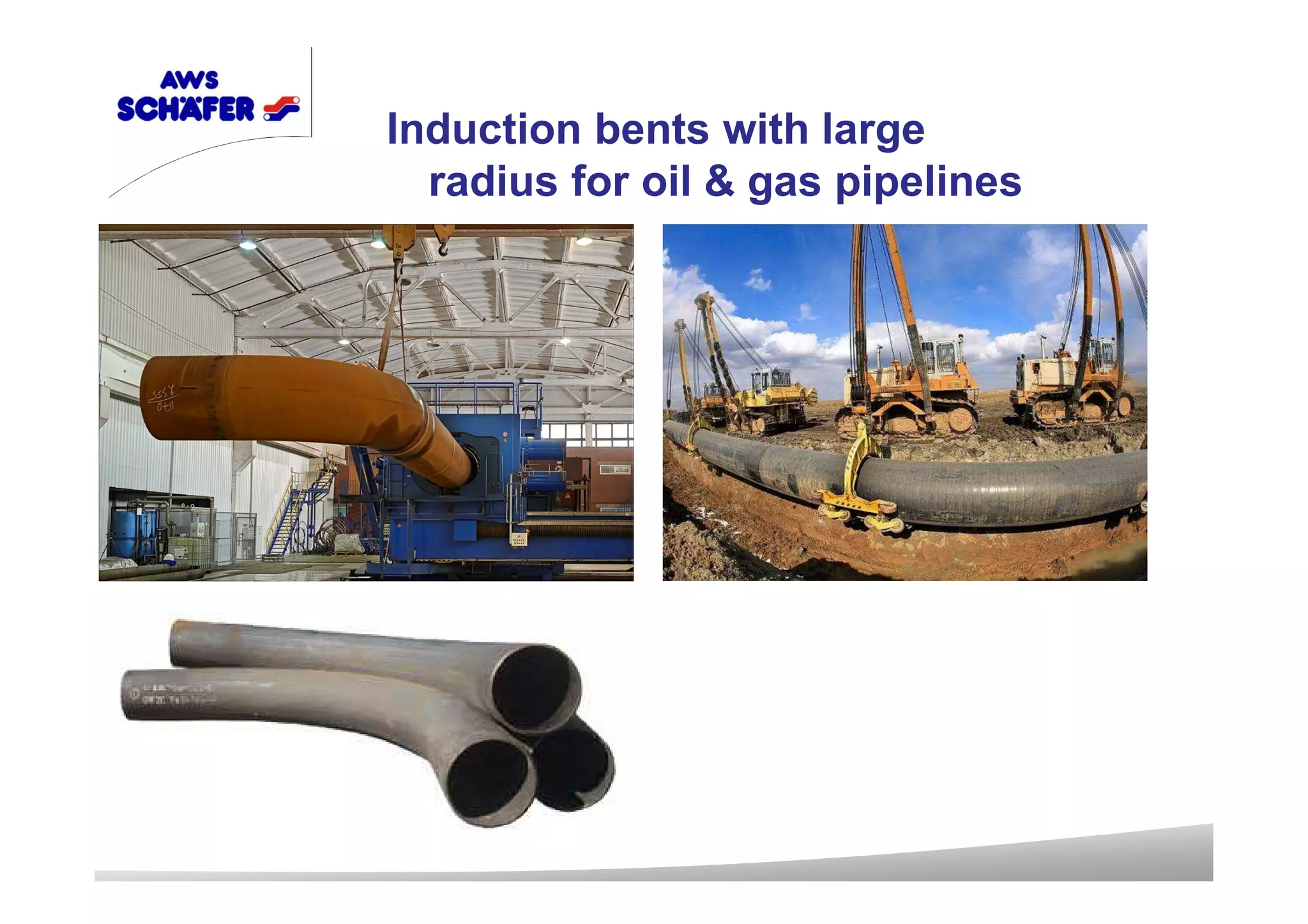

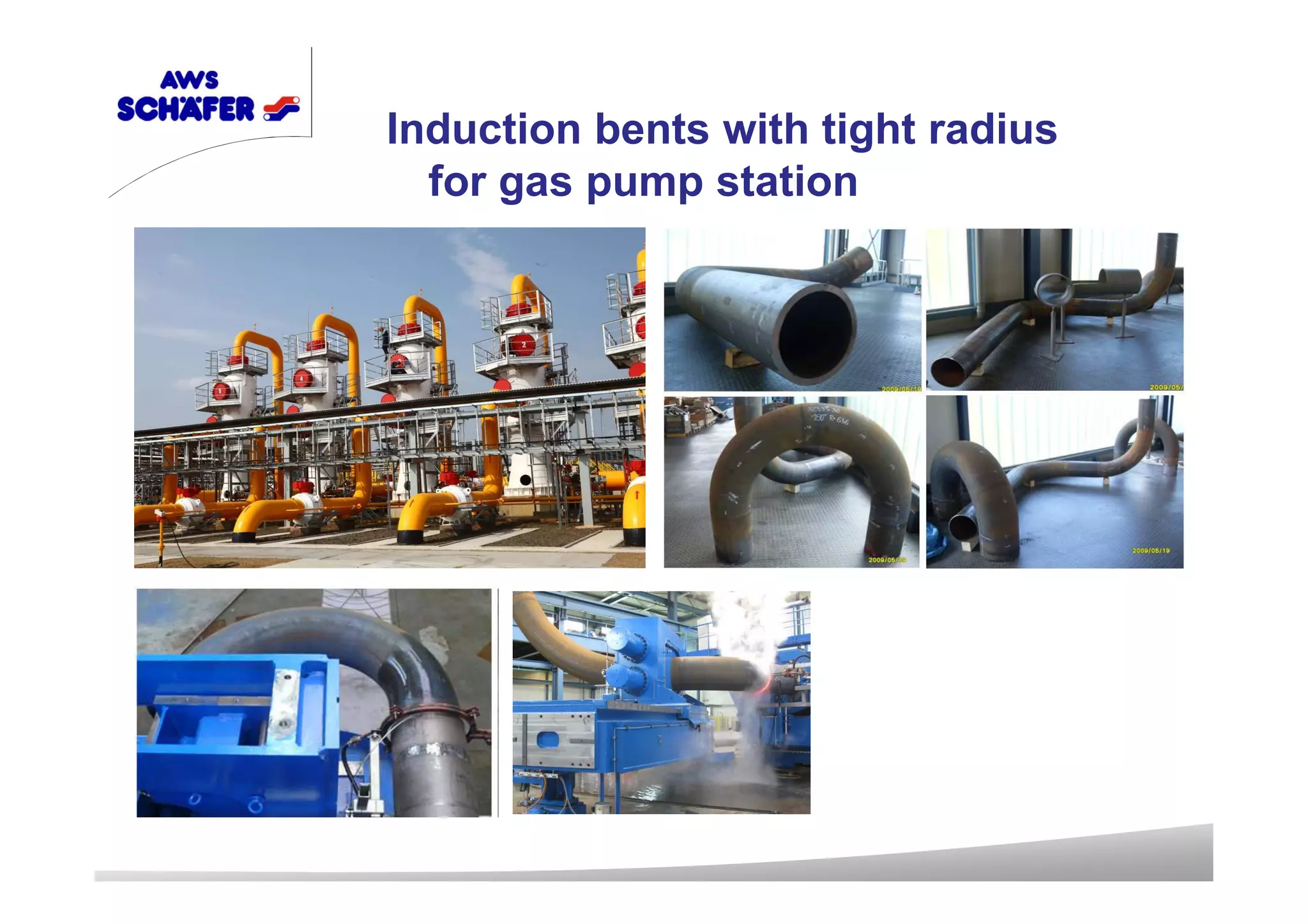

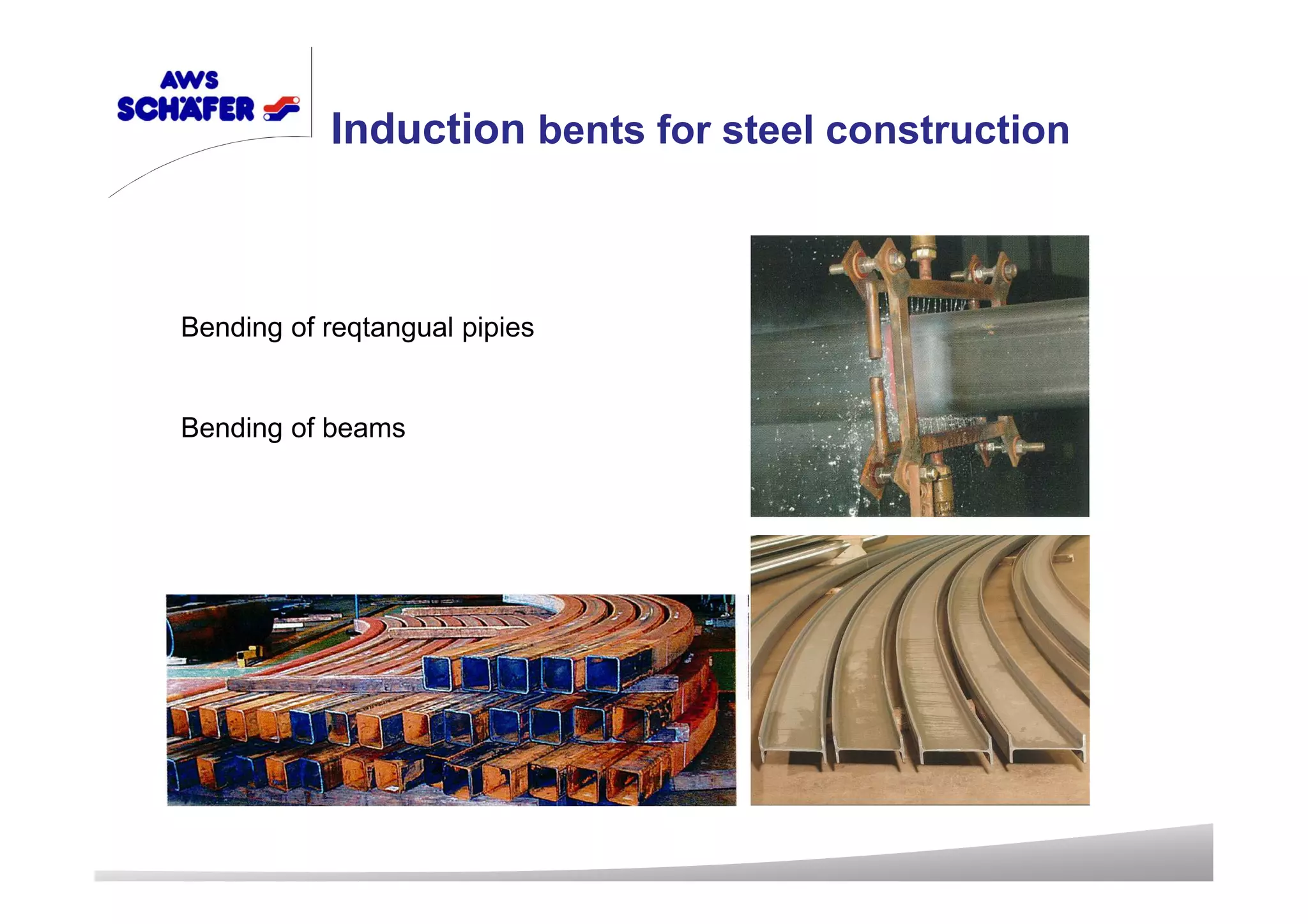

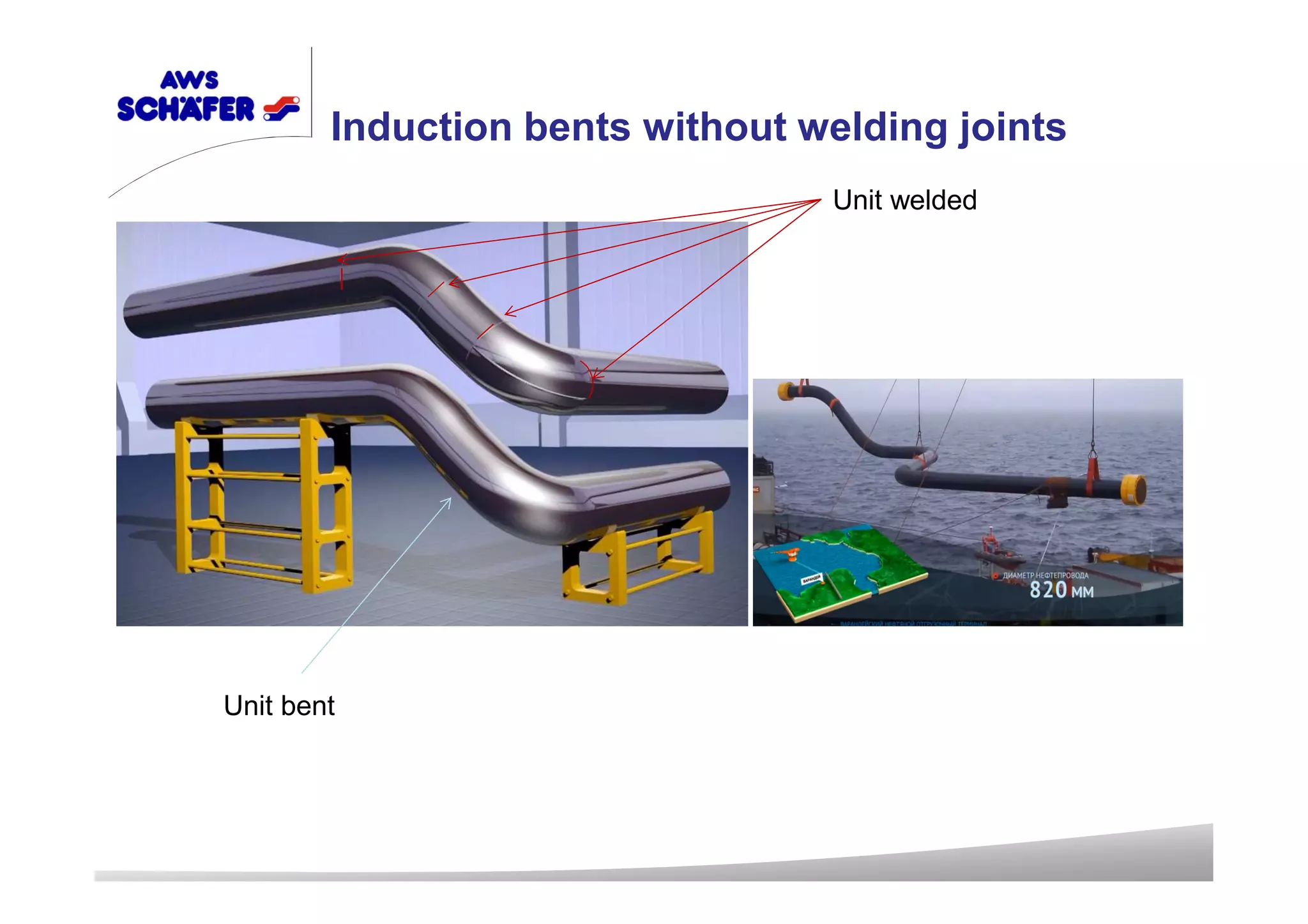

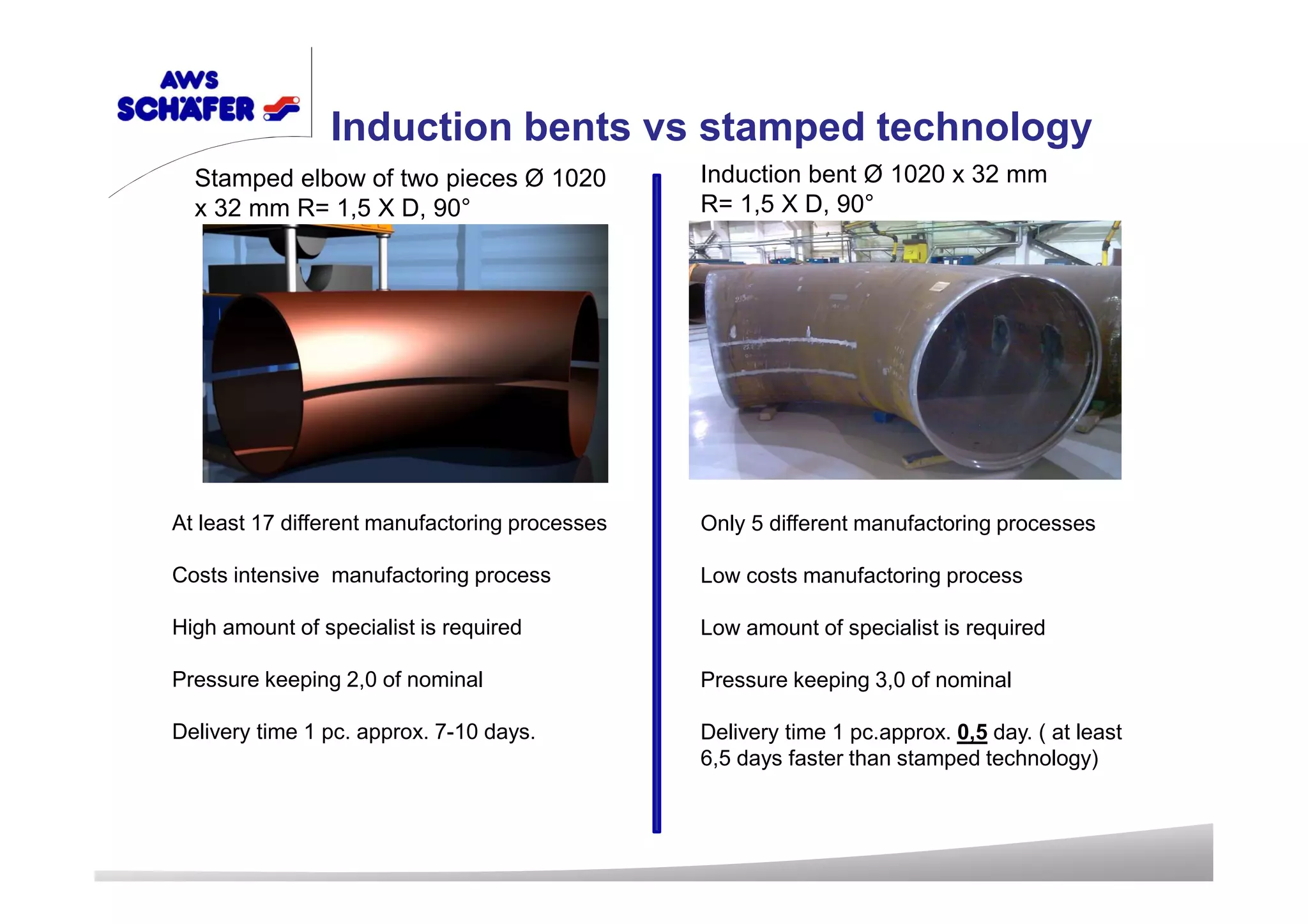

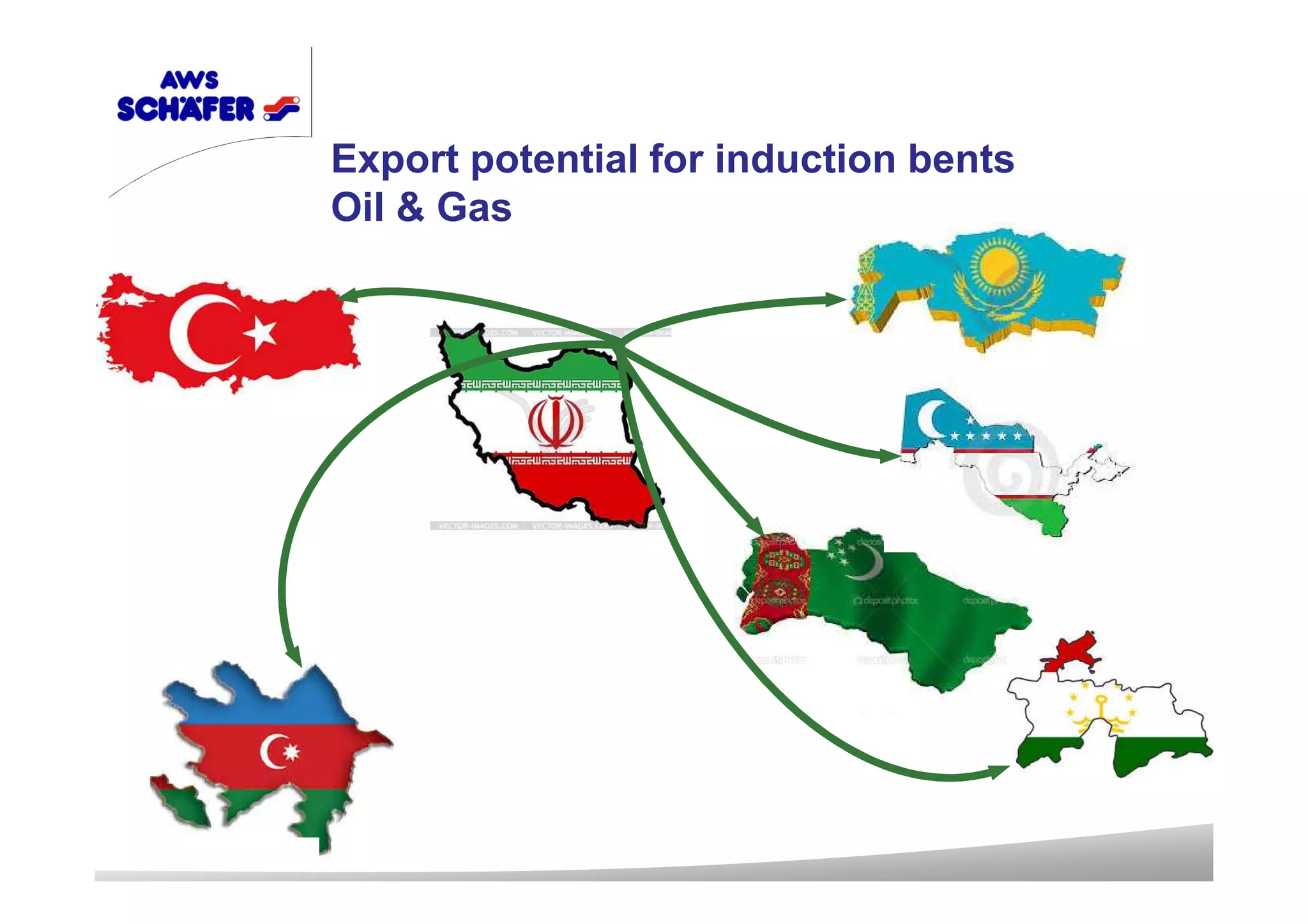

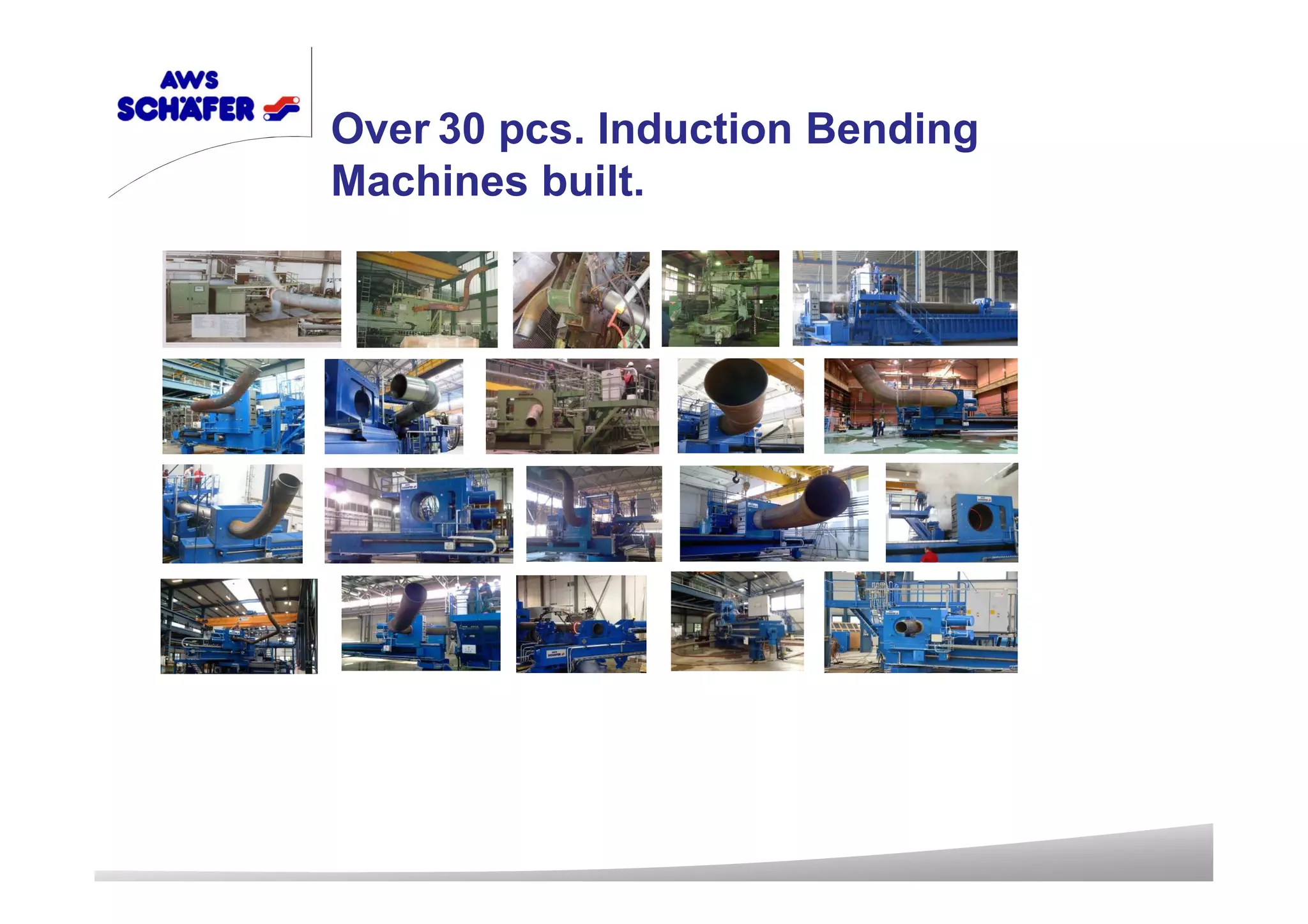

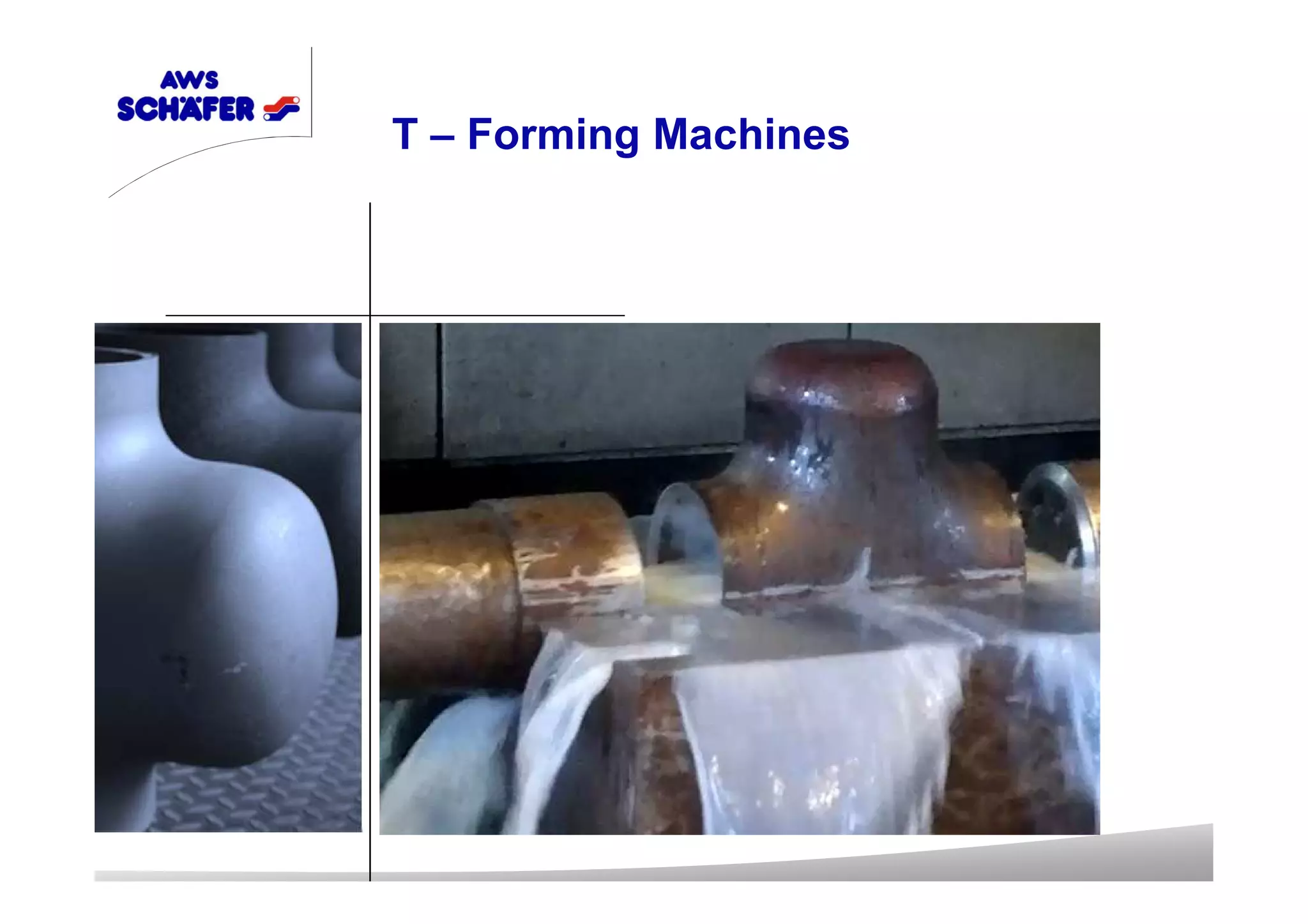

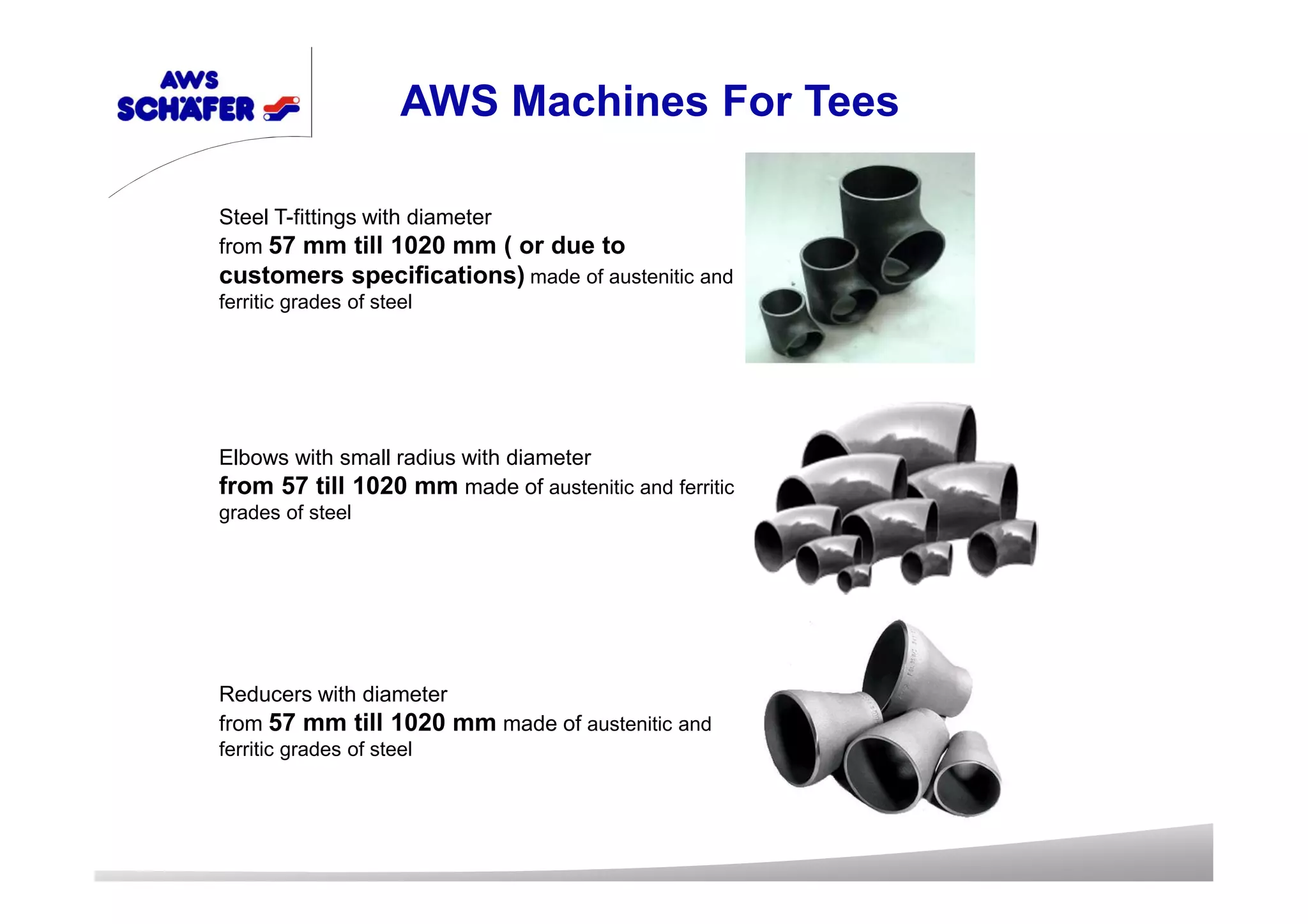

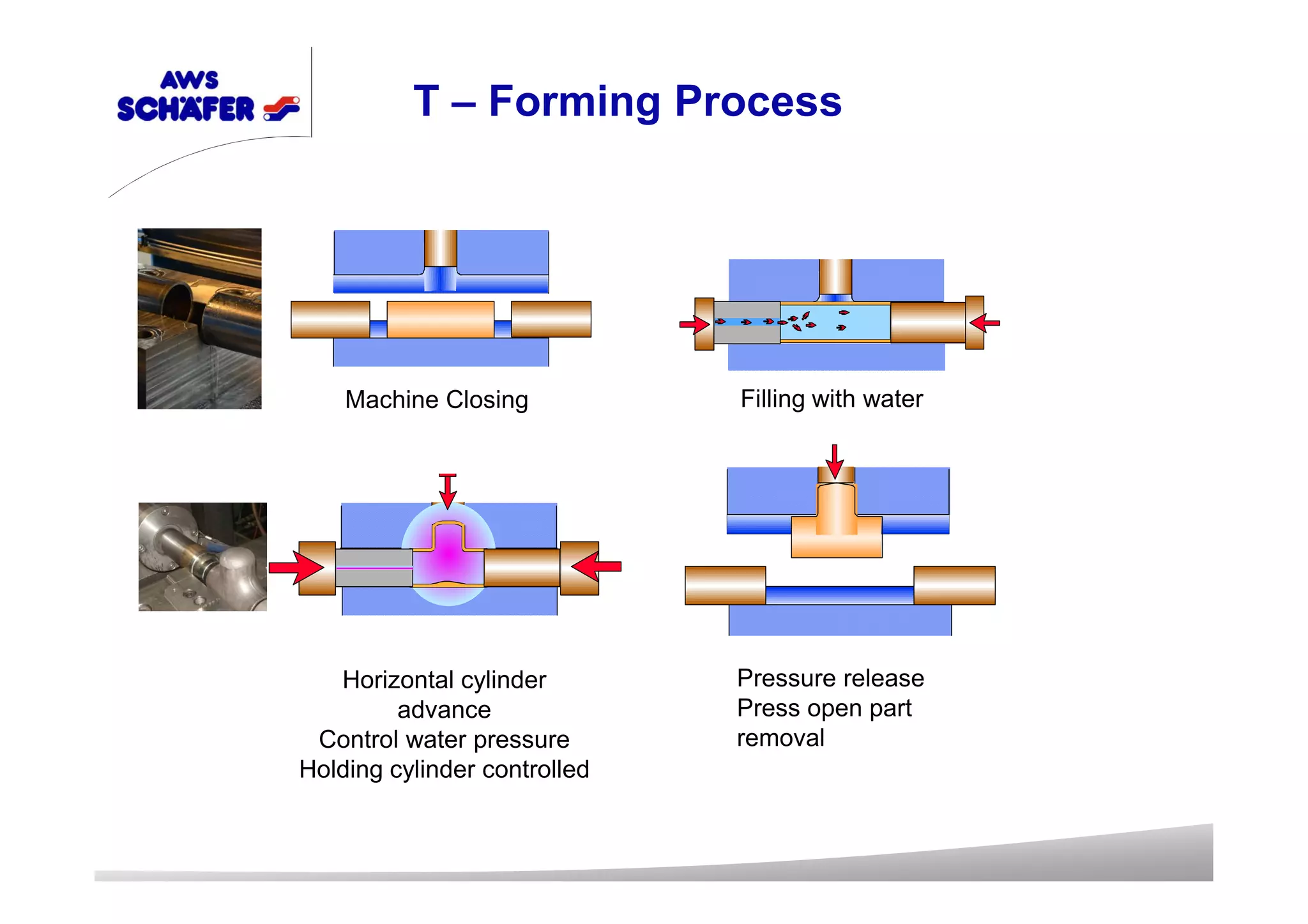

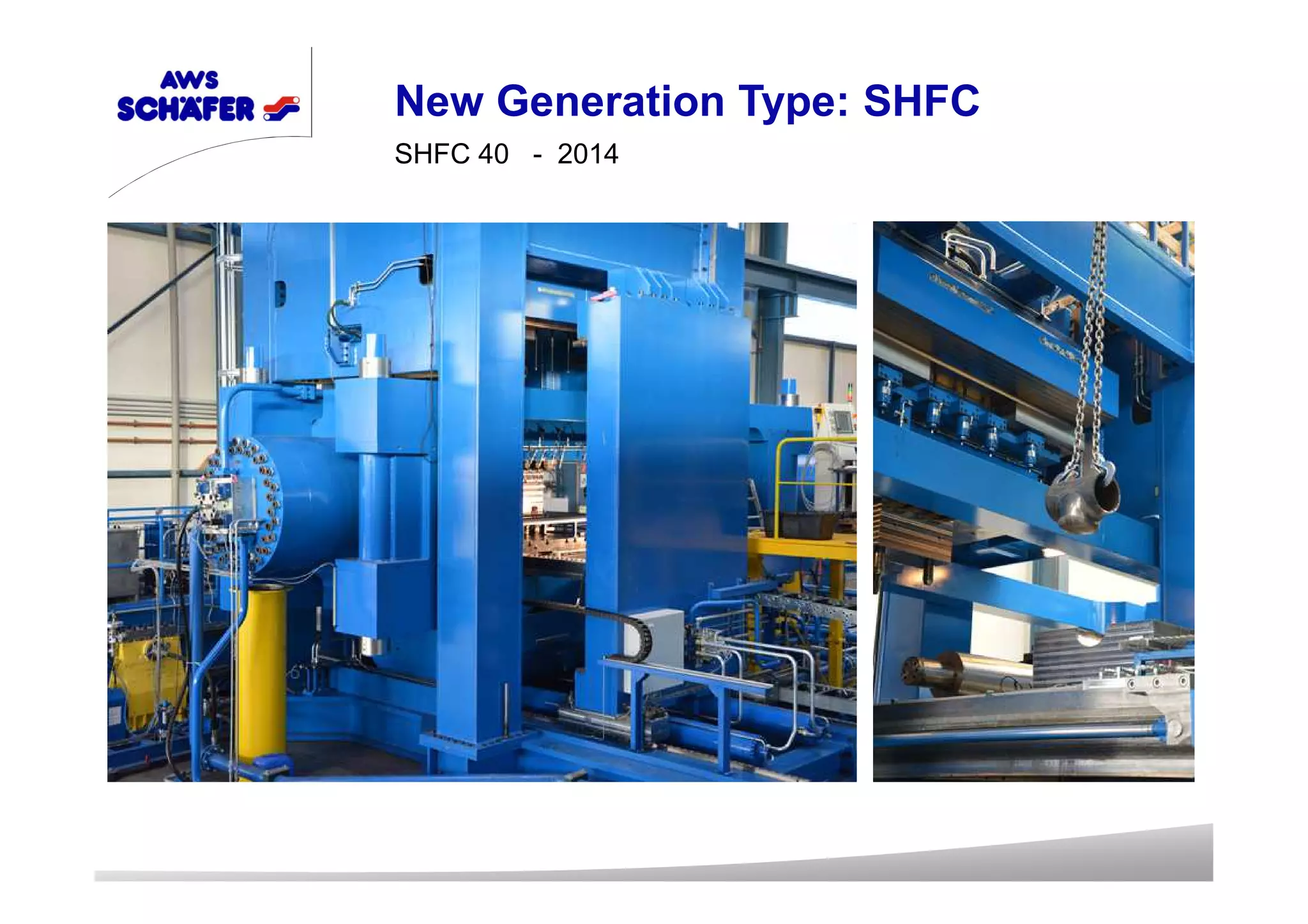

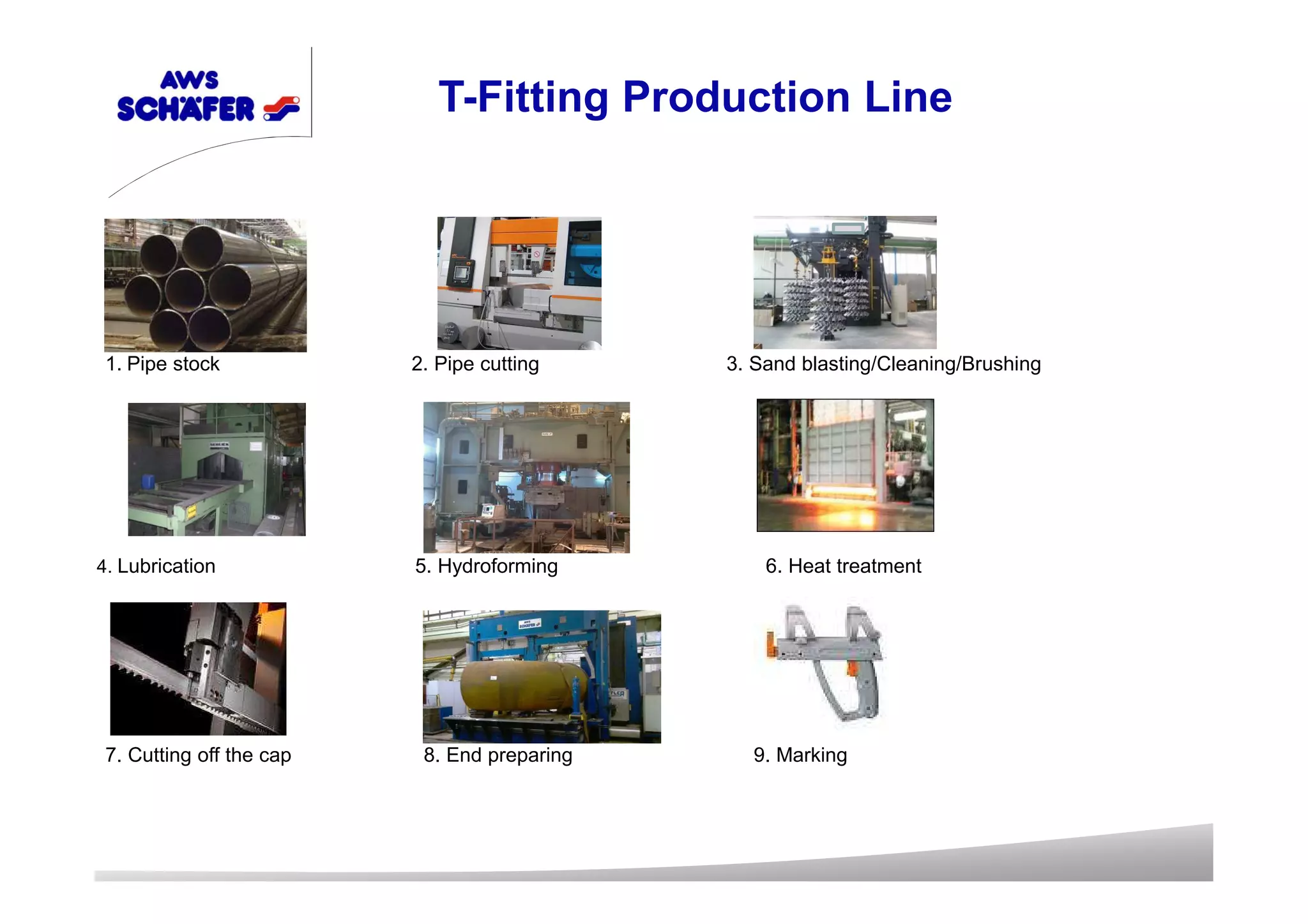

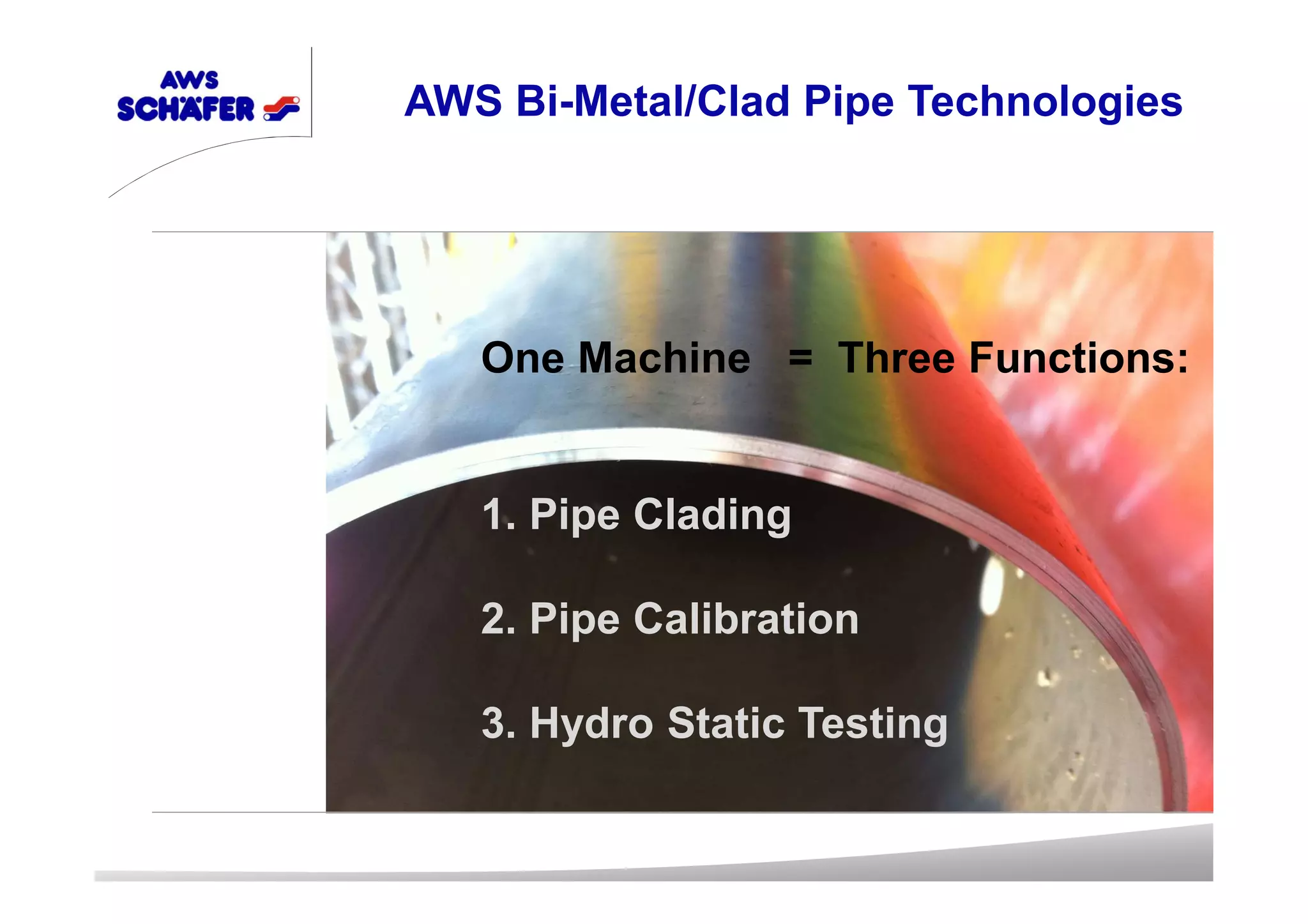

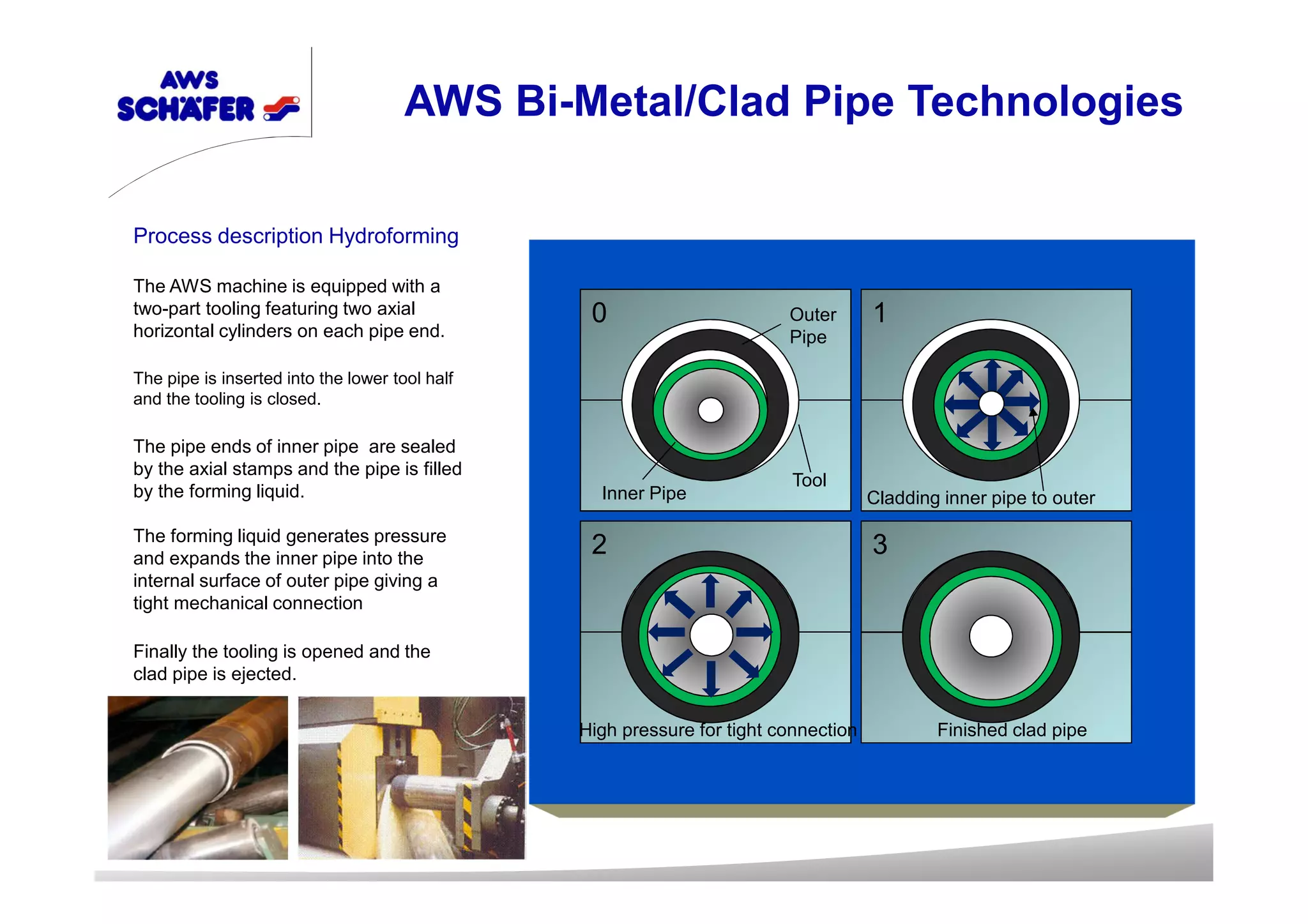

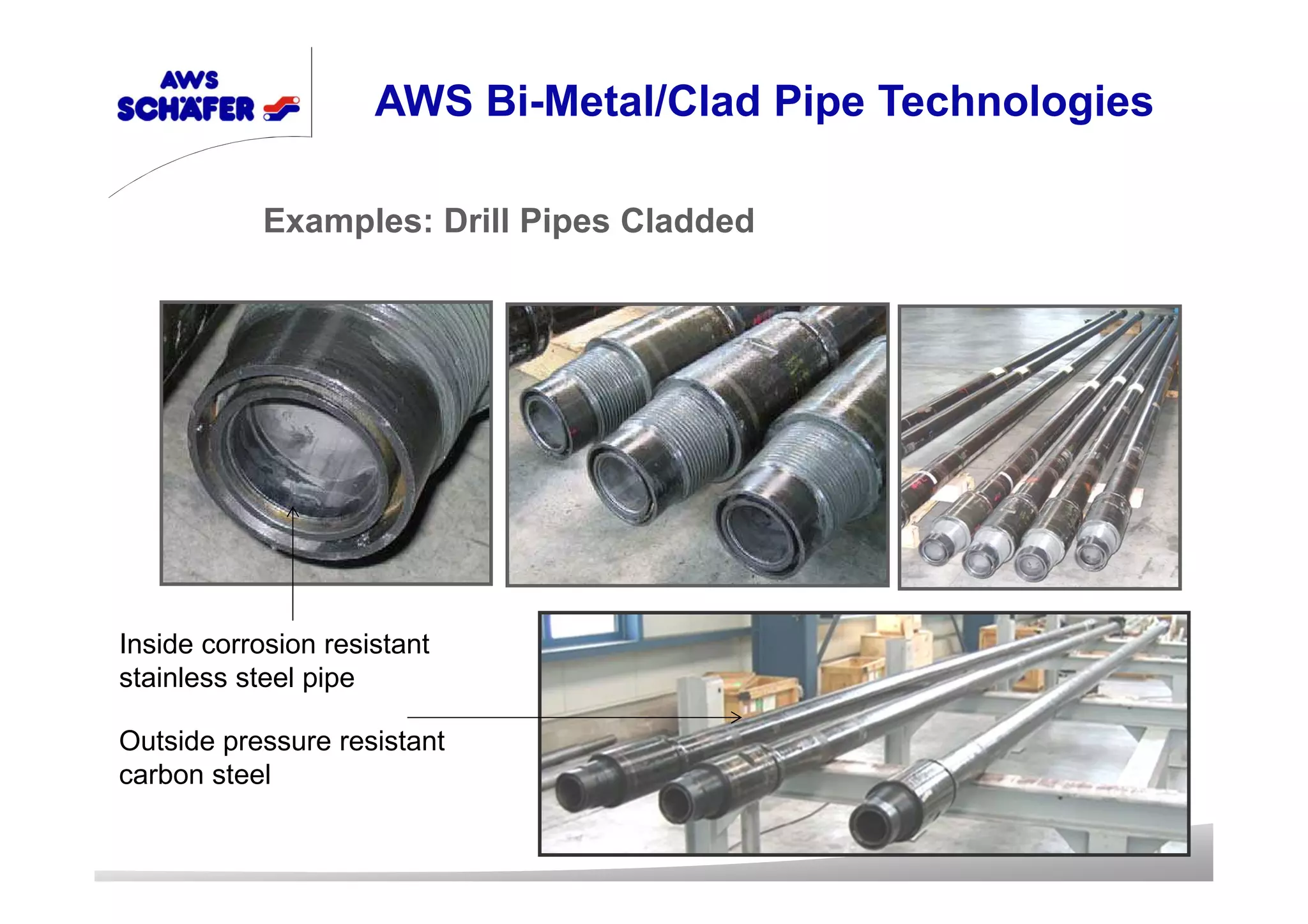

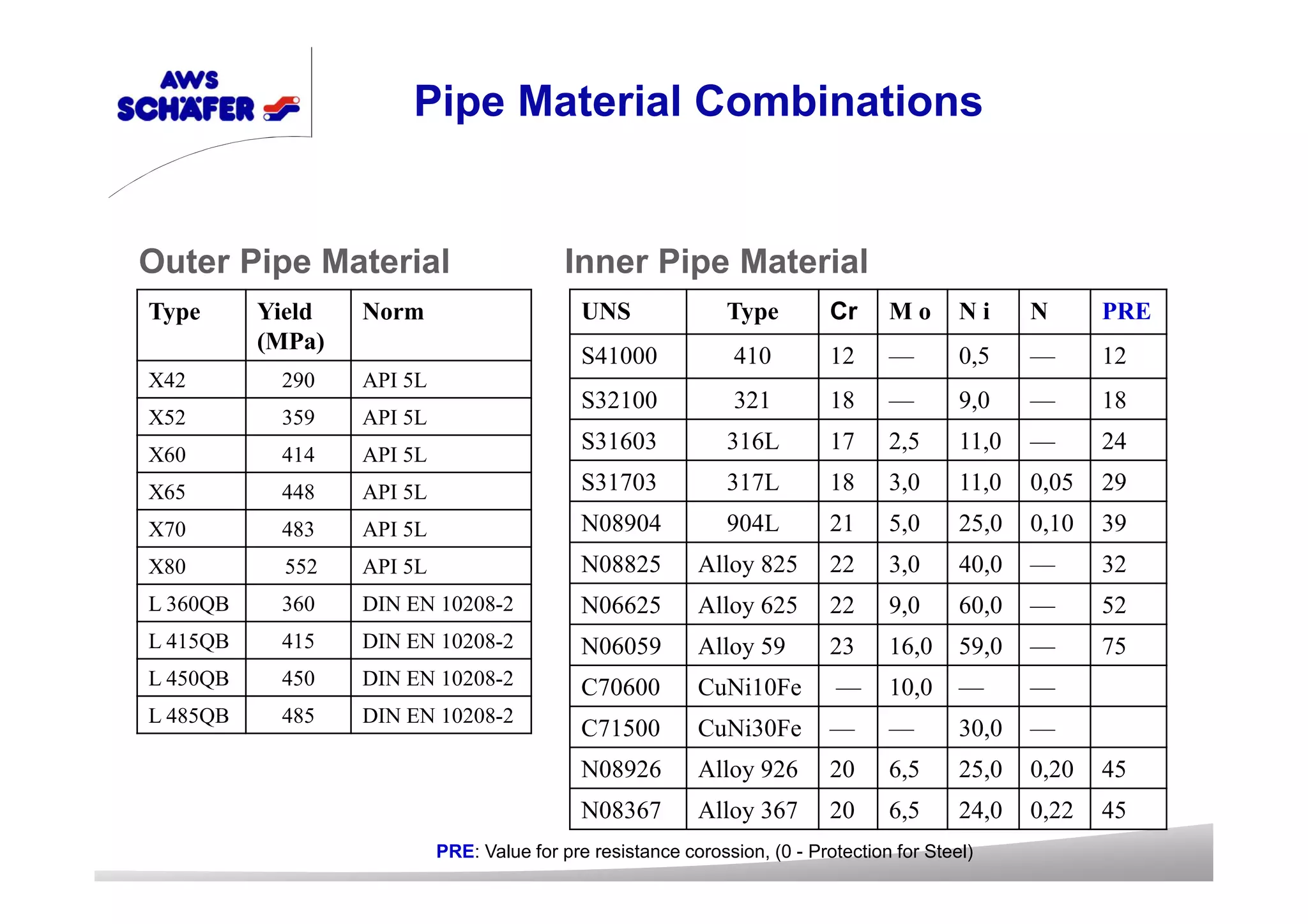

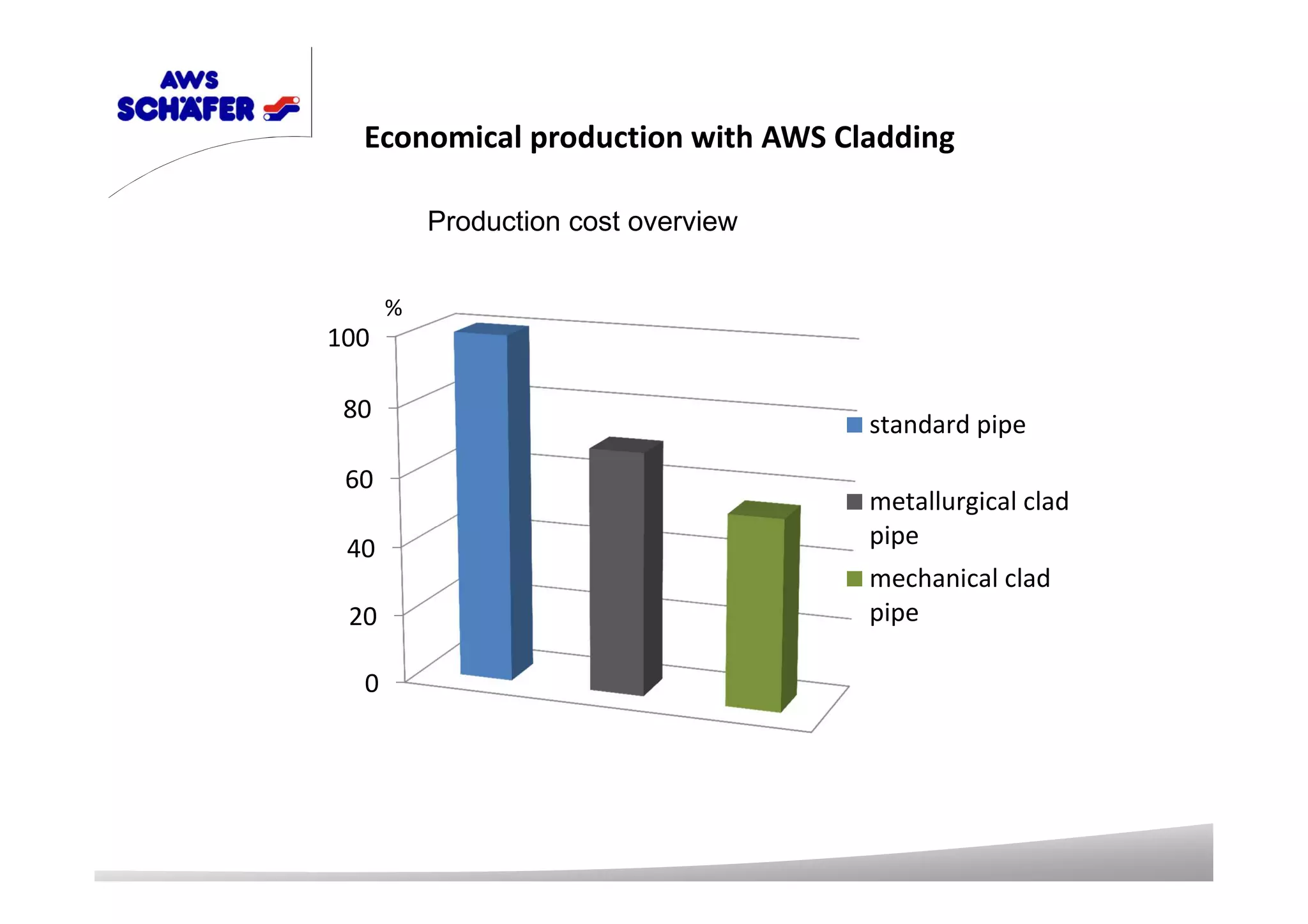

AWS Schäfer has over 50 years of experience manufacturing pipe forming machines. Their induction bending machines can bend pipe with radii from 1.5 times the pipe diameter to 40 diameters, and can preserve straight sections before, after, and between bends. This results in high quality bends with minimal wall thinning and fewer welds. Their hydroforming machines can produce tees from pipe with diameters from 57mm to 1020mm out of various steel grades. Cladding machines can apply a corrosion-resistant inner layer to carbon steel pipe for uses like oil and gas drilling where corrosion is a concern. This extends the lifetime of pipes 10 times compared to carbon steel.