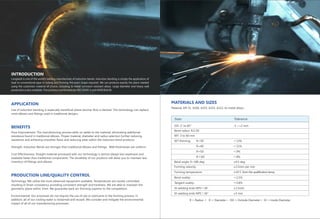

Longtaidi is a leading manufacturer of induction bends that uses induction bending technology to replace elbows and fittings. Induction bending involves applying controlled heat to pipe to form the desired shape. This provides benefits like eliminating welds, maintaining uniform wall thickness for strength, and often being less expensive than traditional components. Longtaidi has advanced equipment to closely control temperatures during forming for consistent quality. Materials bent include carbon steels, stainless steels, and corrosion-resistant alloys in sizes from 2 to 60 inches in diameter.