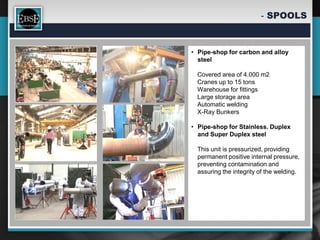

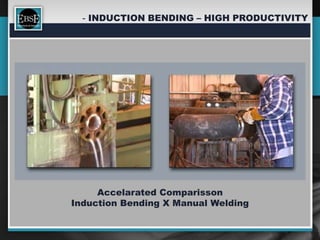

The document discusses The Shaw Group, a Fortune 500 company that provides engineering, construction, and manufacturing services globally. It has over 28,000 employees, 139 US locations, and 33 international locations. The company has various certifications and specializes in pipe spools through automated and high productivity welding and bending, including complex large diameters and special steel types. Induction bending is described as a highly productive method of bending pipe.