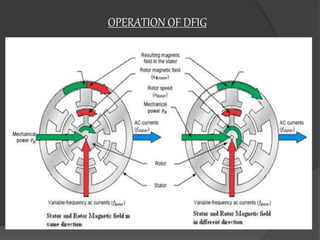

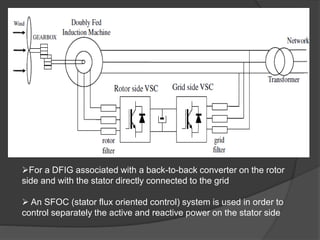

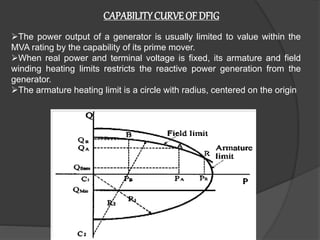

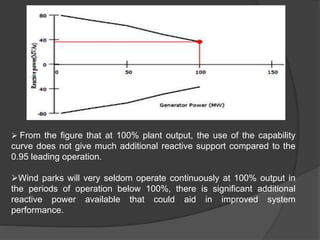

The document discusses the reactive power capability (rpc) of doubly fed induction generators (DFIG) in grid-connected systems, highlighting its limitations and operational characteristics. It emphasizes the importance of converter rating and PWM selection to enhance rpc, and the role of DFIGs as a reactive resource compared to traditional synchronous generators. The conclusion suggests that adopting a capability curve for DFIG wind farms could improve their efficiency and regulatory compliance.