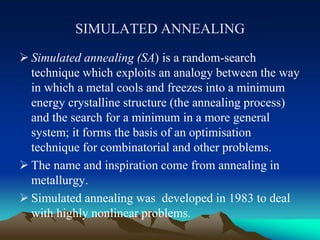

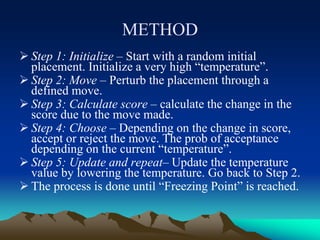

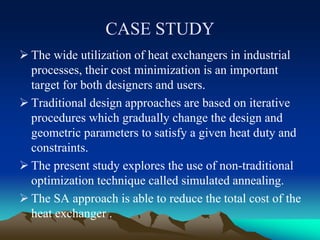

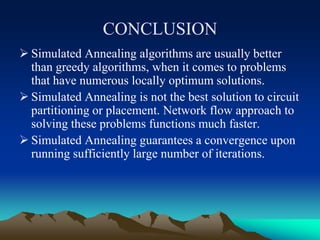

The document discusses simulated annealing, a random-search optimization technique inspired by the annealing process in metallurgy, developed in 1983 for nonlinear problems. It outlines the method which includes initialization, perturbation, and temperature-controlled acceptance of moves, demonstrating its application in optimizing industrial processes like heat exchangers. While simulated annealing is effective for problems with many local optima, it has limitations compared to other methods like network flow algorithms.