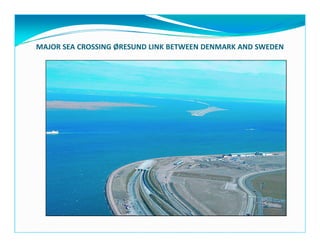

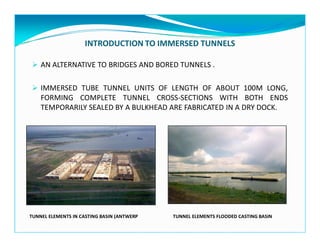

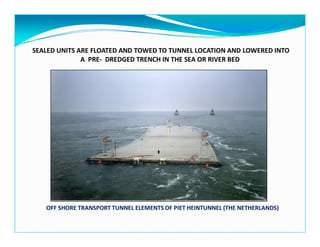

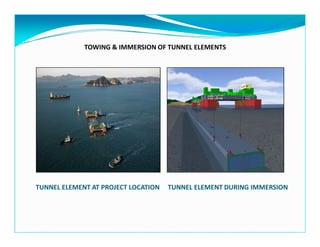

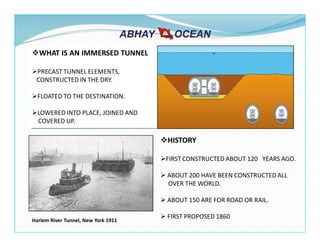

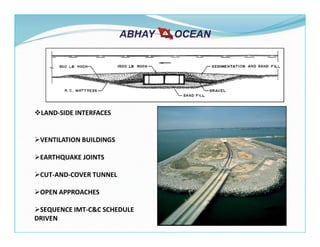

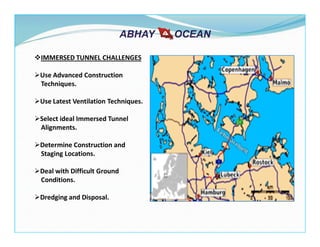

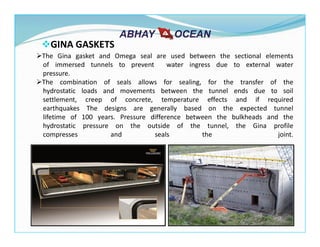

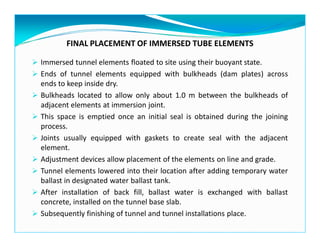

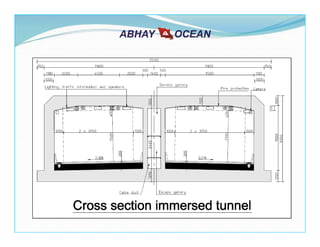

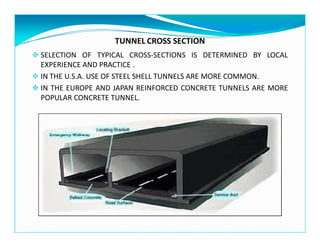

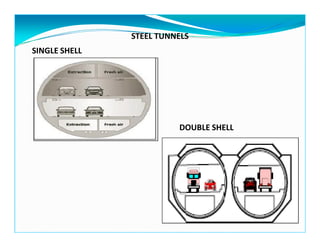

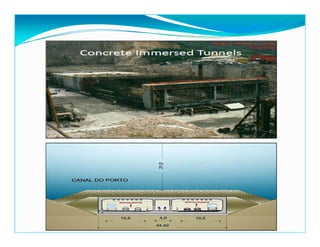

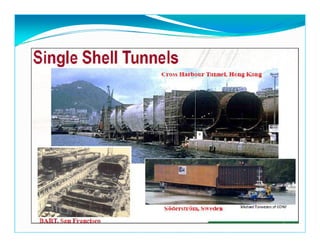

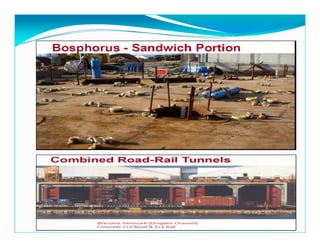

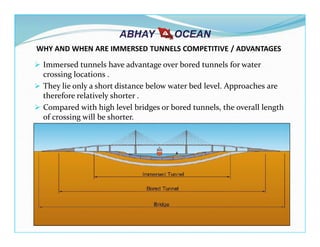

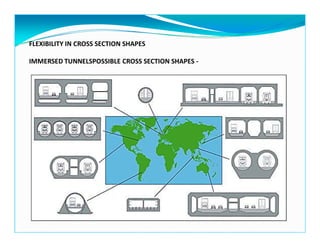

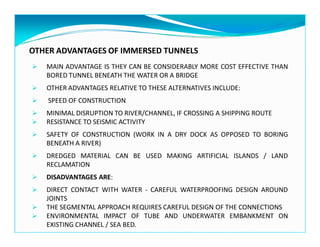

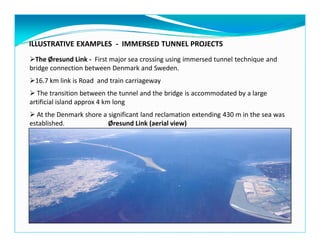

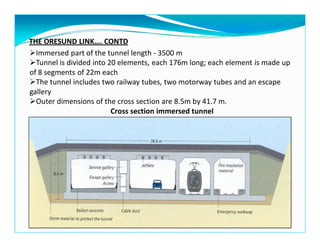

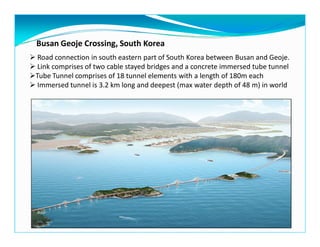

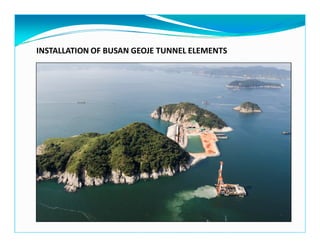

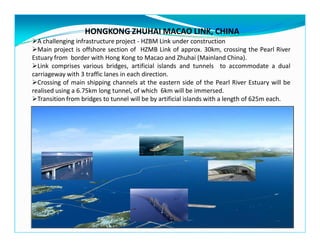

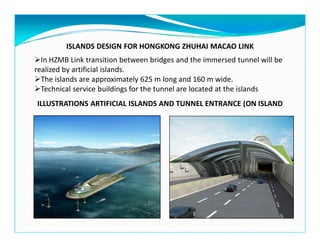

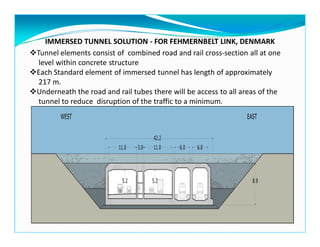

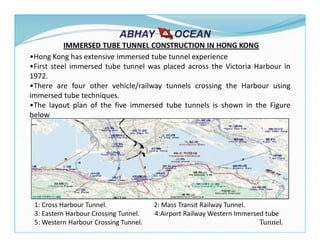

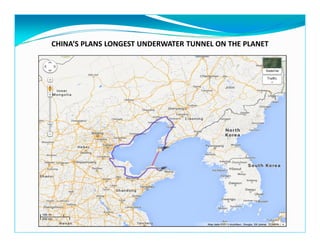

The document provides an introduction to immersed tube tunnel technology. It discusses how immersed tunnels are an alternative to bridges and bored tunnels for large sea crossings. Immmersed tunnel elements are constructed in a dry dock, floated and lowered into a pre-dredged trench, and joined together using gaskets to form a continuous tunnel. Several major immersed tunnel projects from around the world are described such as the Oresund Link between Denmark and Sweden and the planned Hong Kong-Zhuhai-Macao Link tunnel crossing. The challenges of immersed tunnel construction and their advantages over other options are also summarized.