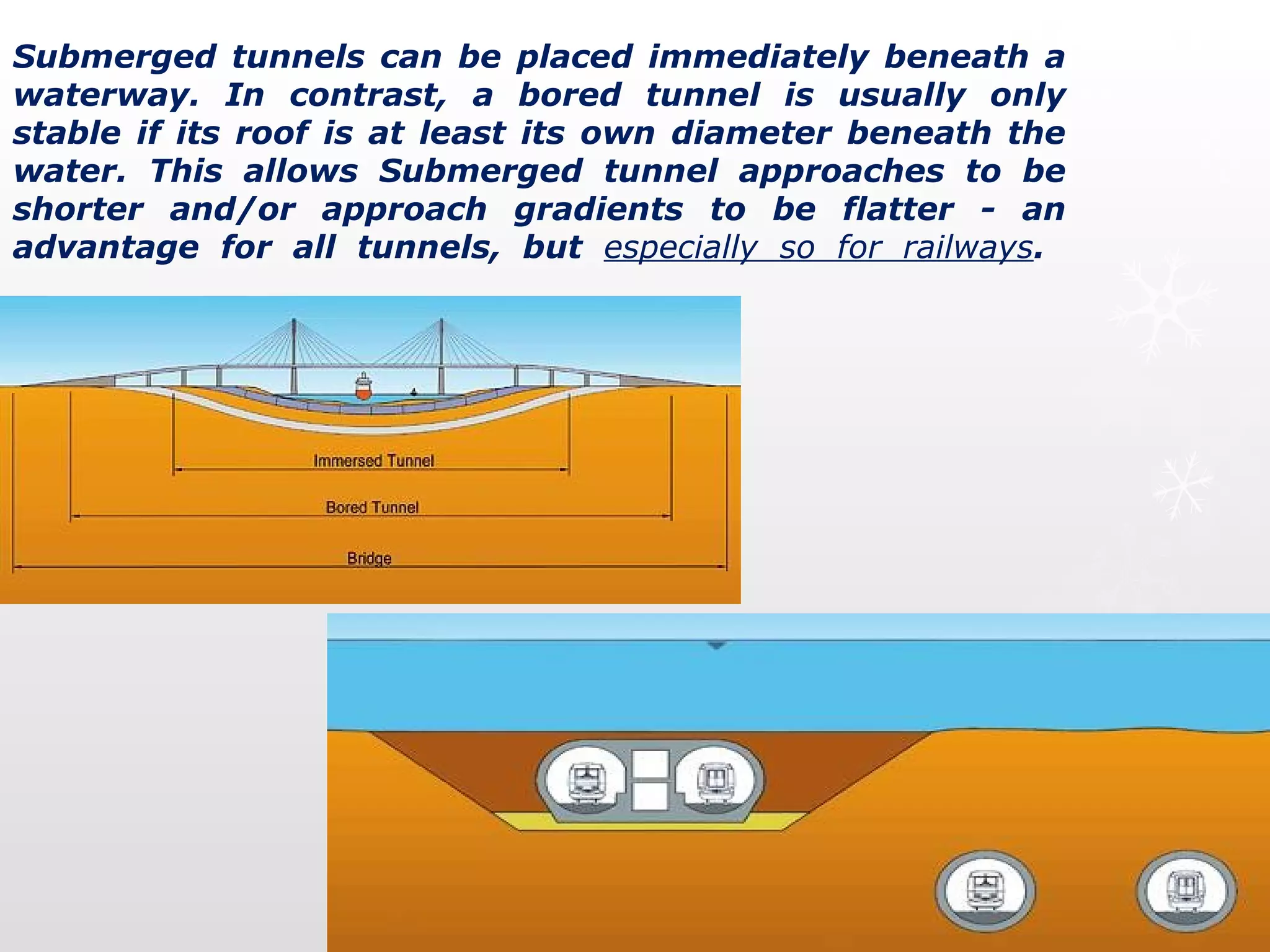

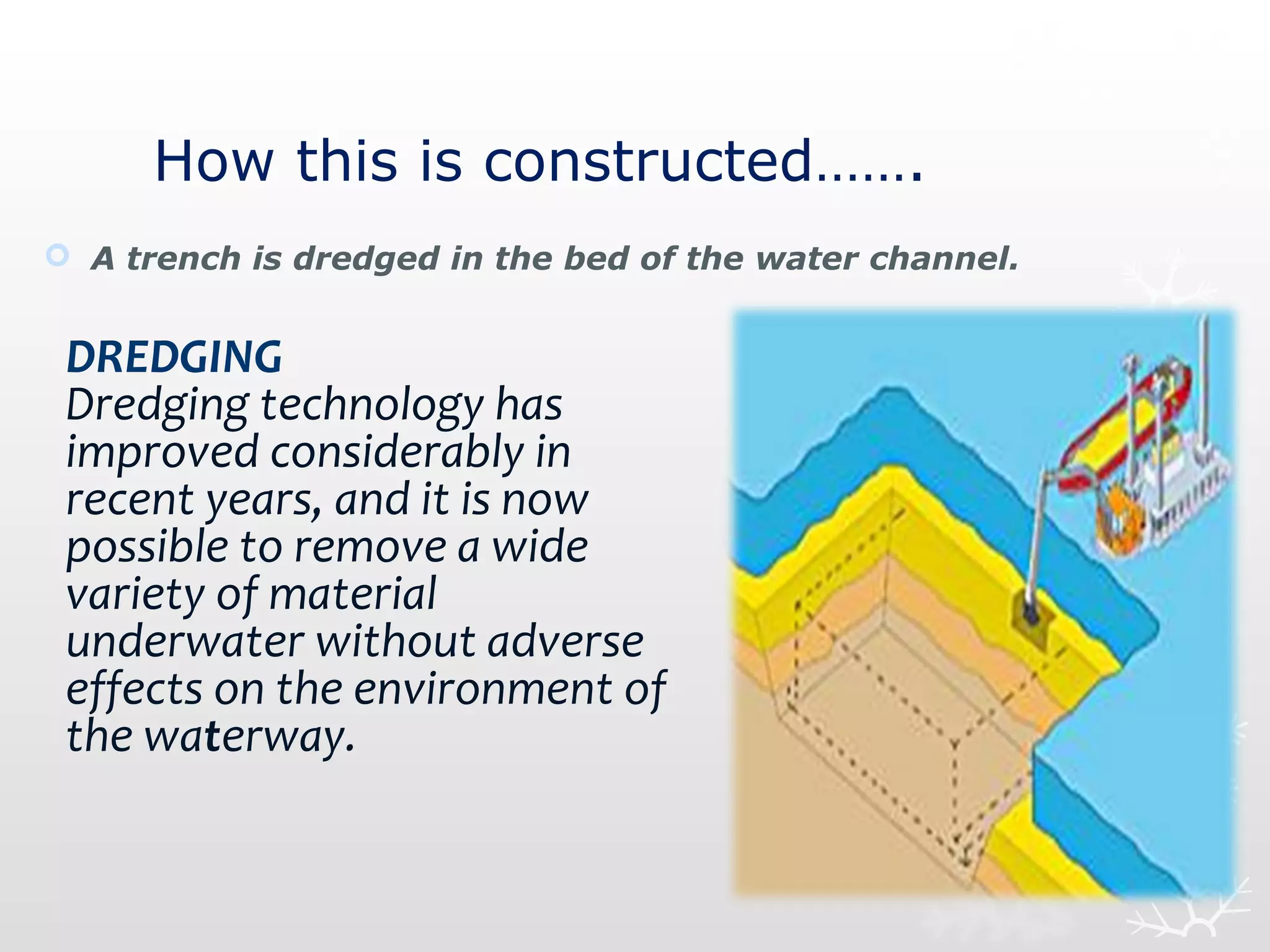

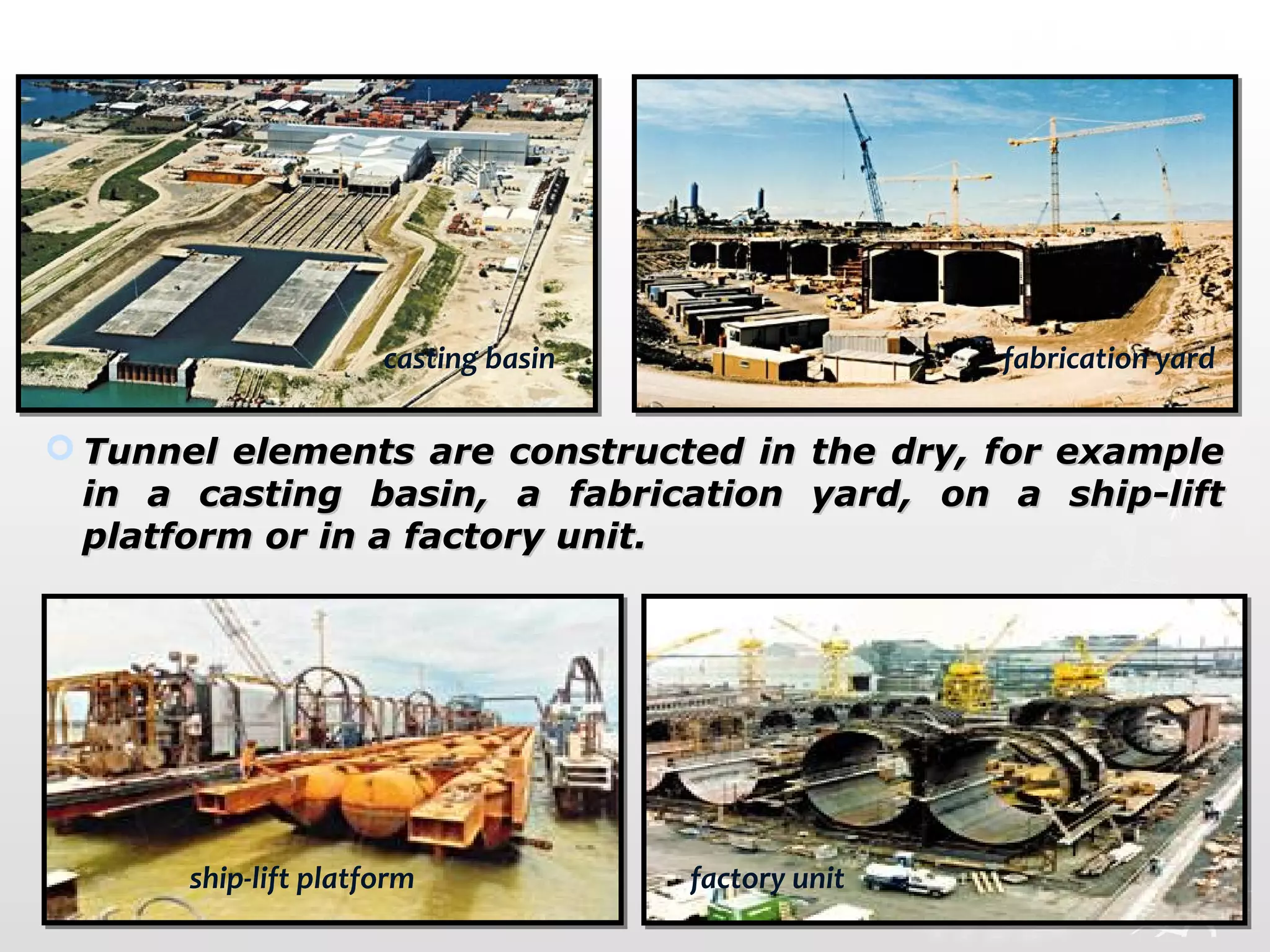

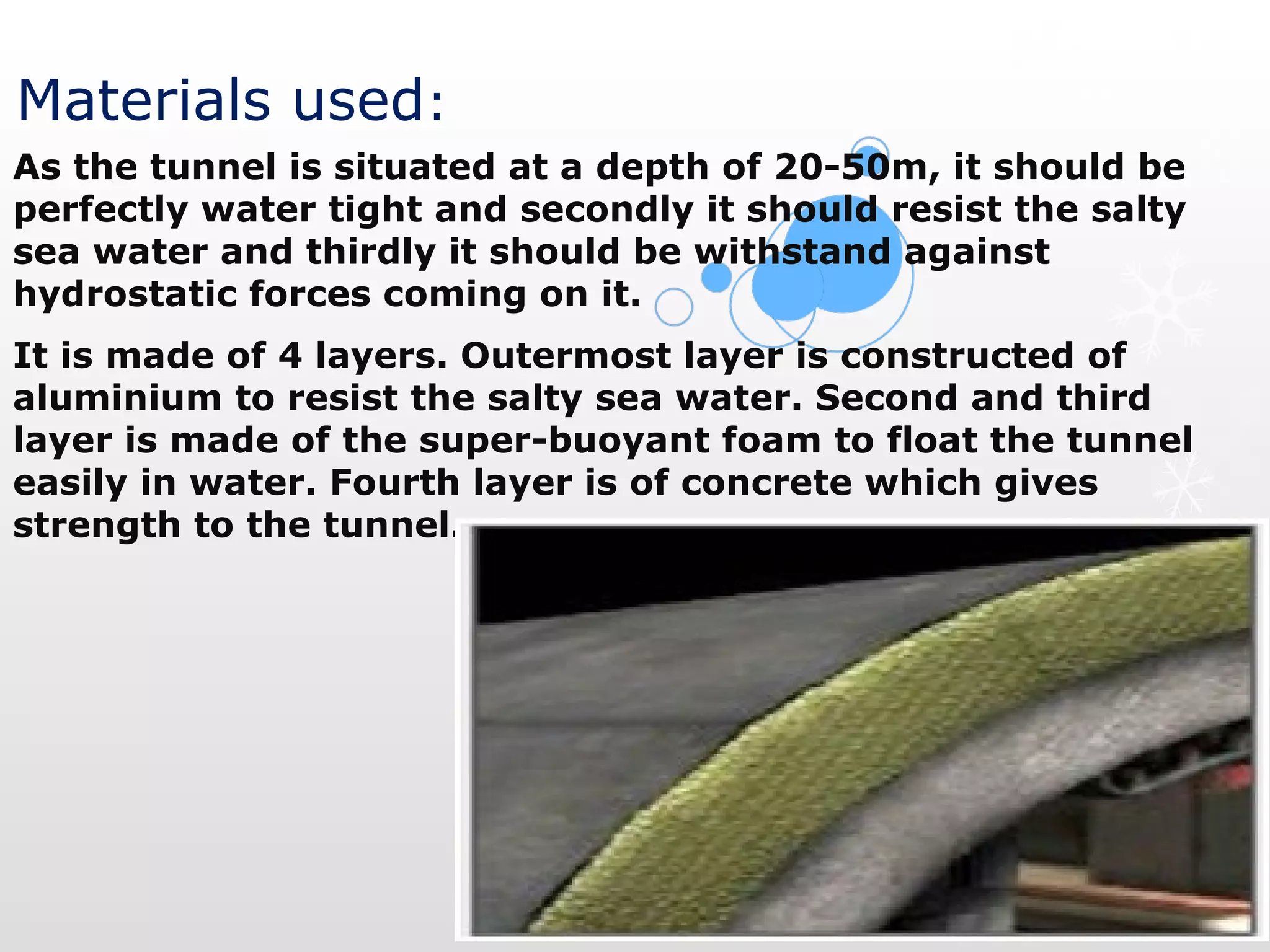

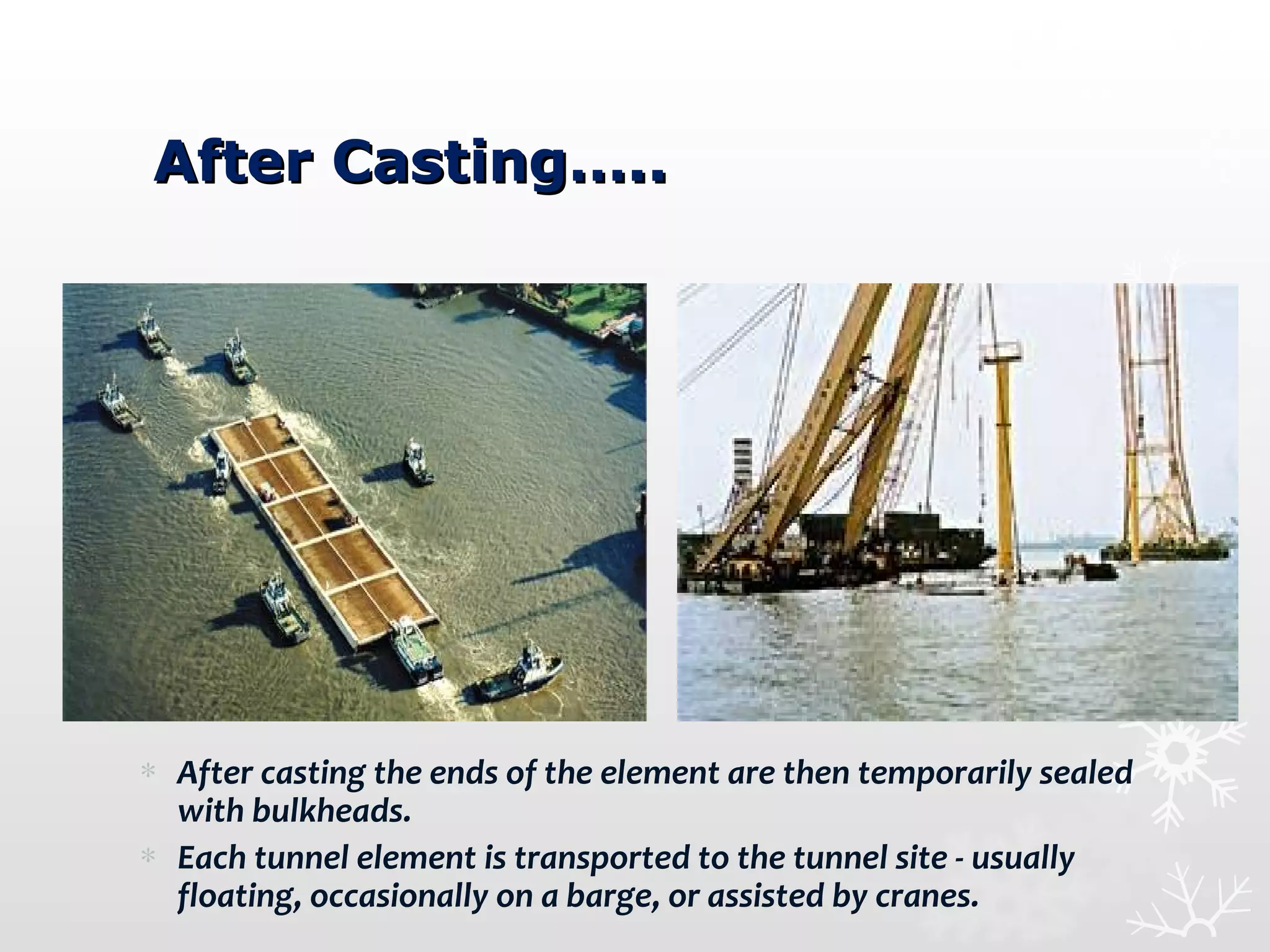

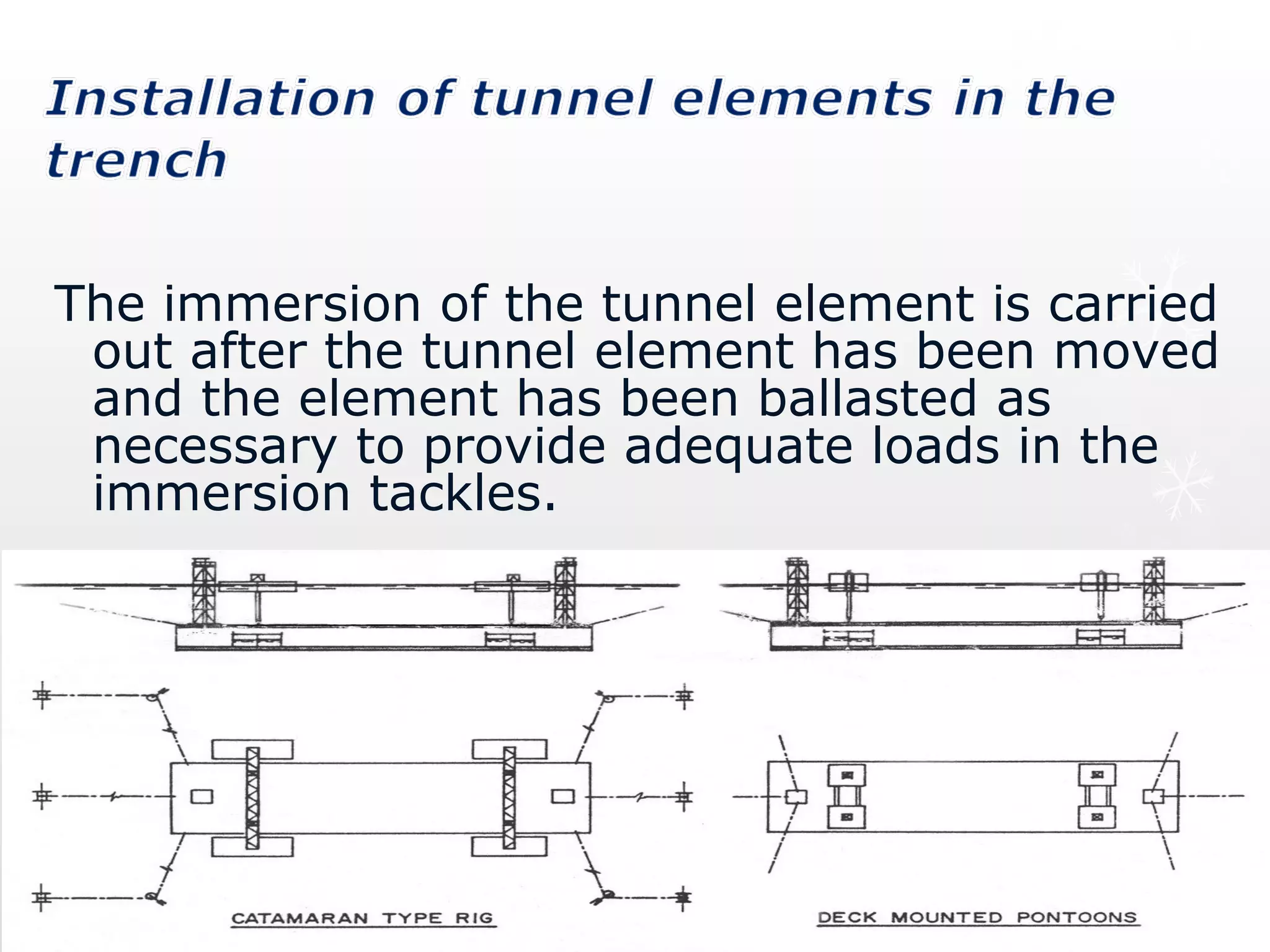

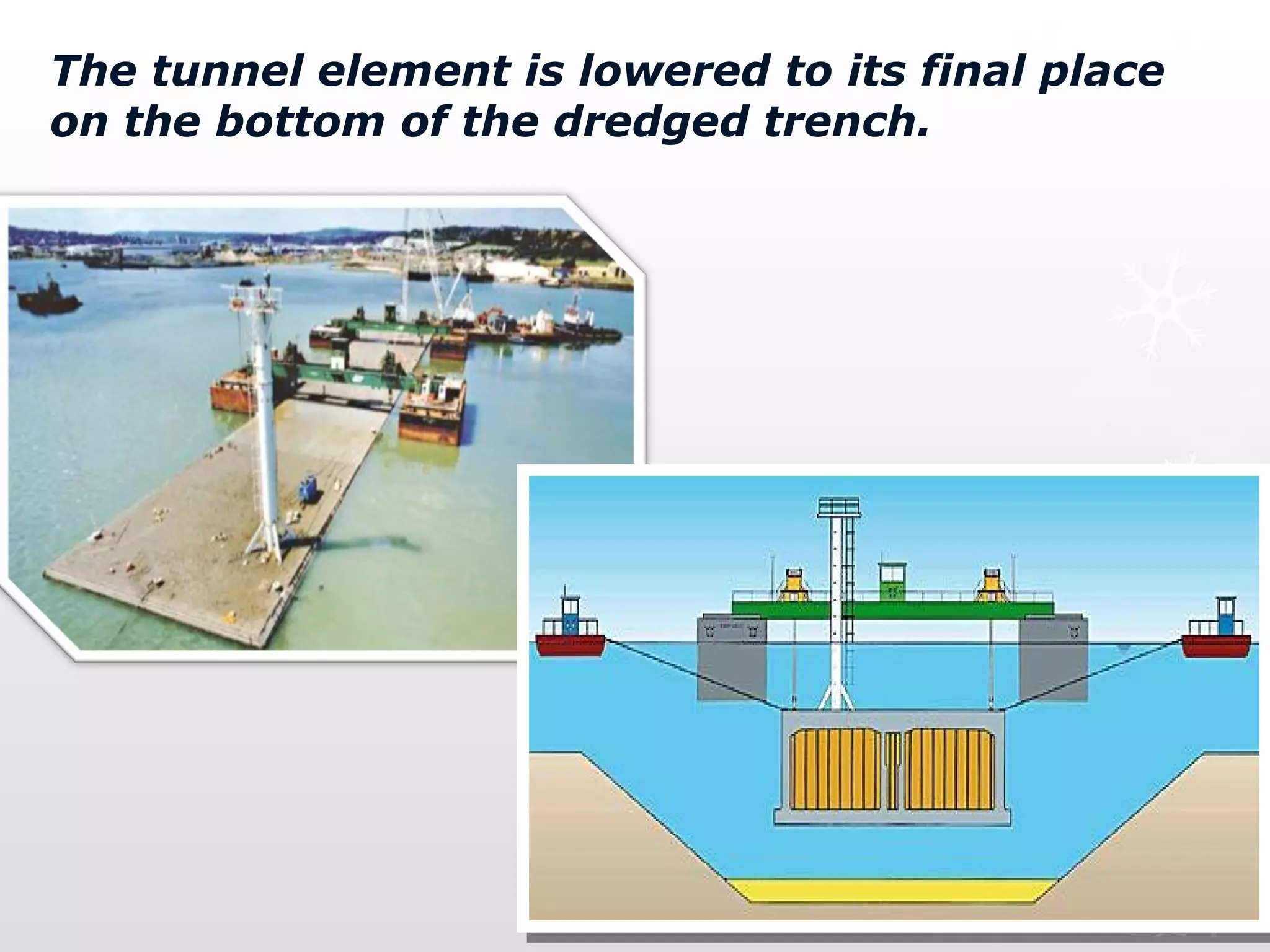

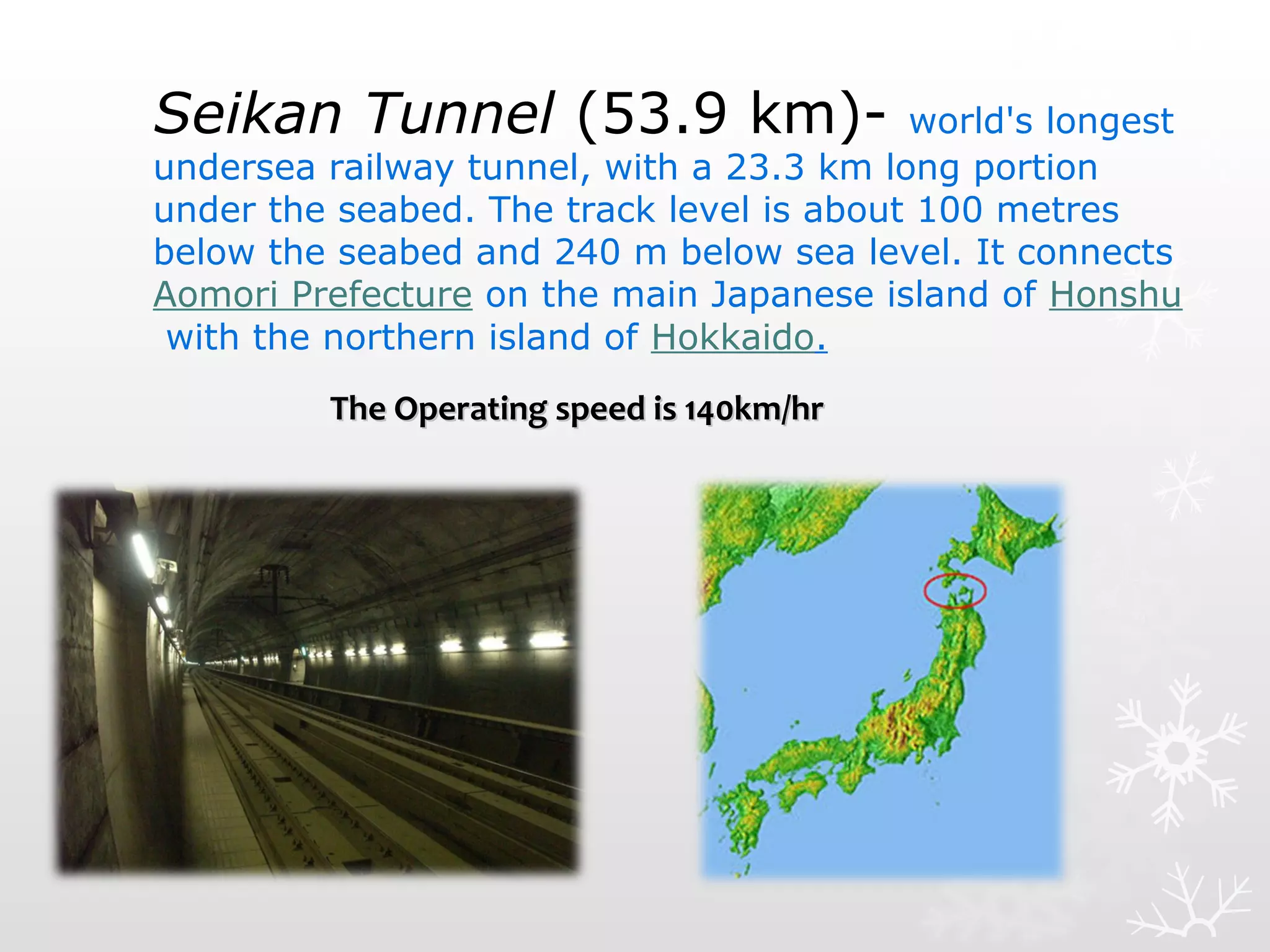

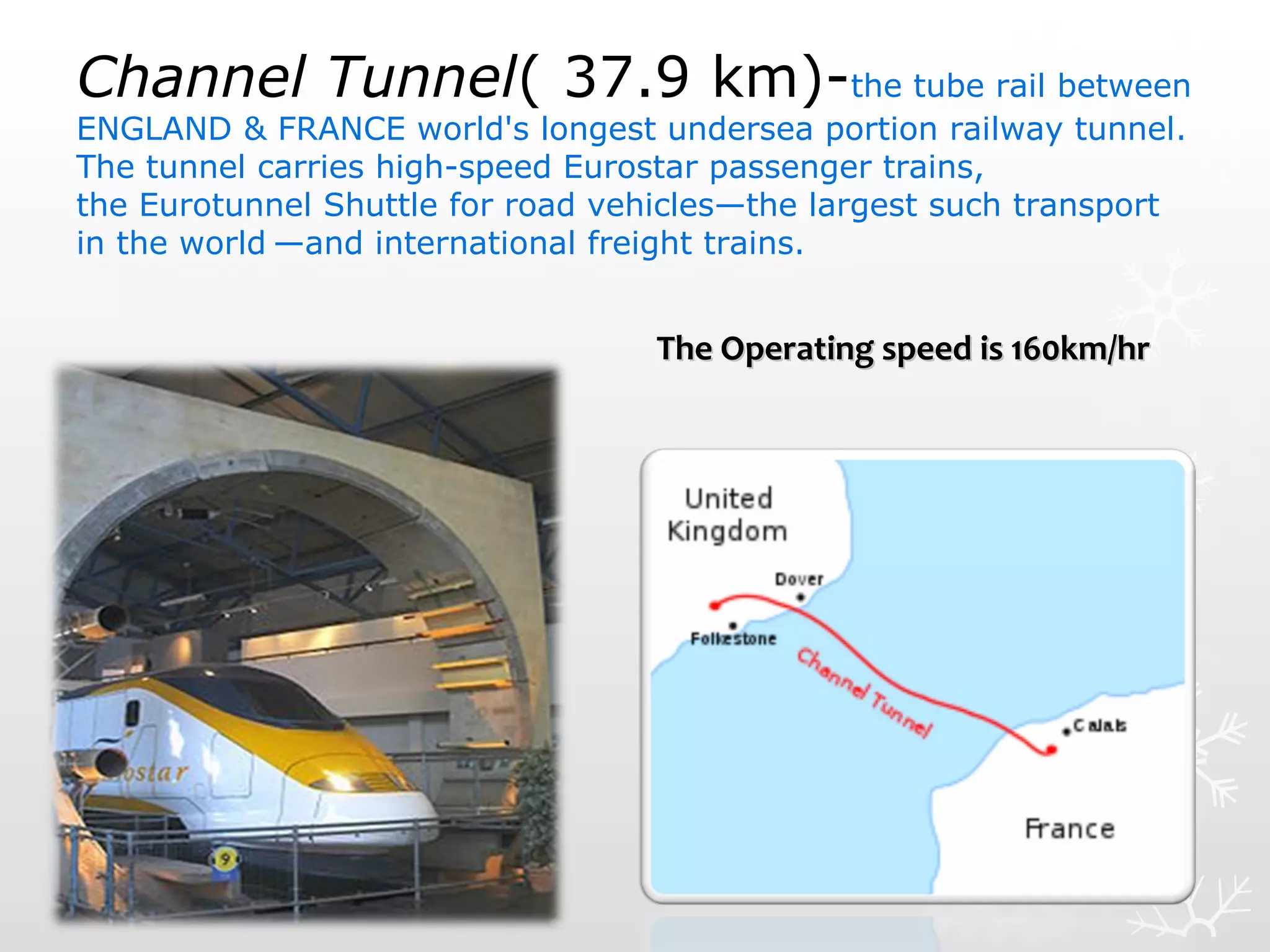

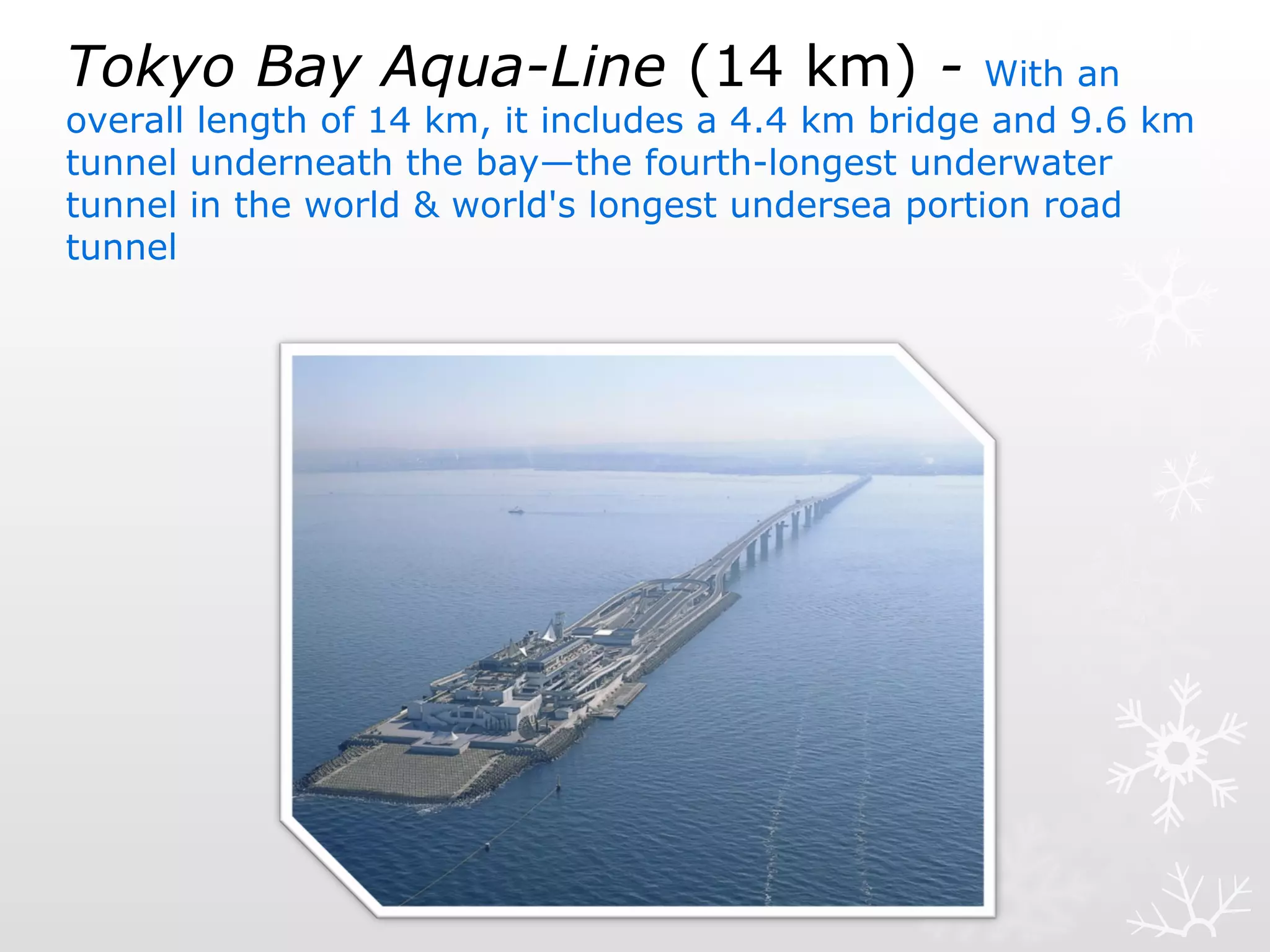

The document discusses submerged tunnels, which are passages built under bodies of water for various uses including transportation and utility purposes. These tunnels are constructed using prefabricated sections that are floated and sunk into dredged trenches, and they offer advantages such as reduced weight, faster construction, and less impact on seabed chemistry. Case studies of notable submerged tunnels like the Seikan and Channel Tunnels are provided to illustrate their scale and functionality.