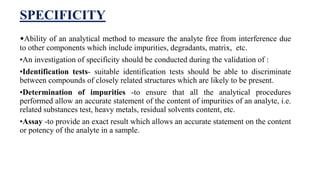

The ICH guidelines provide validation requirements for analytical procedures including accuracy, precision, specificity, linearity, range, limit of detection, and limit of quantification. Accuracy and precision should be established across the specified range and determined using multiple concentration levels in triplicate. Precision has three levels - repeatability under short-term conditions, intermediate precision over longer time periods and varied conditions, and reproducibility between laboratories. The limits of detection and quantification establish the lowest levels that can be detected and quantified. Linearity is evaluated across several concentration levels and statistical measures. The range demonstrates performance within the intended concentrations. Specificity ensures no interference from impurities or matrix.