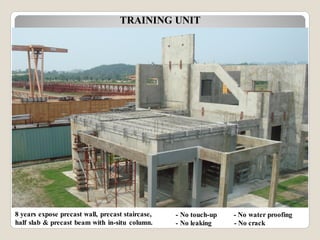

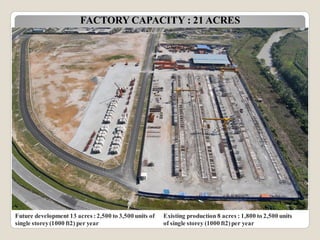

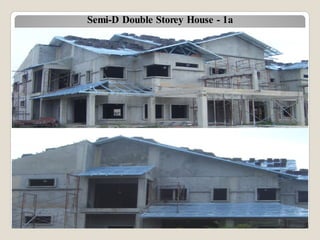

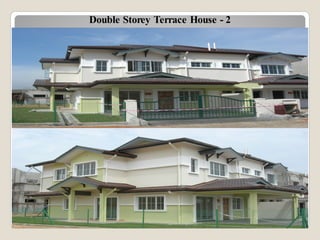

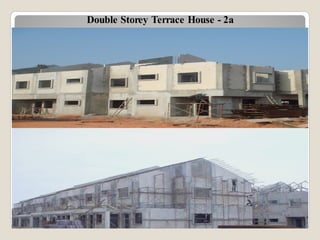

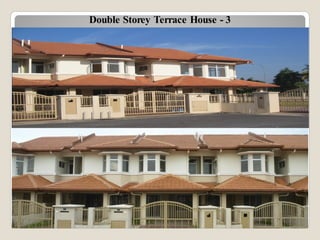

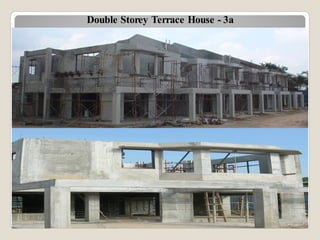

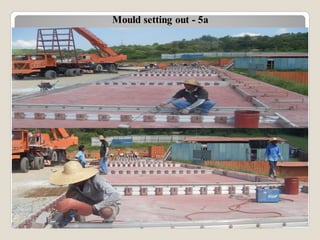

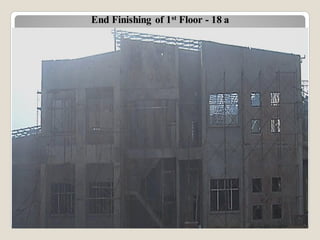

The HC Precast System is a patented industrialized building system in the U.S. and Malaysia designed for efficient construction with customizable wall thicknesses and fire resistance. It minimizes site work by providing a complete precast building system, reducing the need for traditional brick wall assembly and enhancing construction speed and quality. The system aims to invite partnerships with government and private developers to demonstrate its benefits in terms of quality, speed, and environmental impact.